Adjustable resistance knob repair method

A knob and resistor technology, applied in the manufacture of adjustable resistors, resistors, and resistors, can solve the problems of the difficulty of adjustable resistor cores, and achieve the effects of less difficulty in replacement, low production costs, and reduced experimental costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention will be further described:

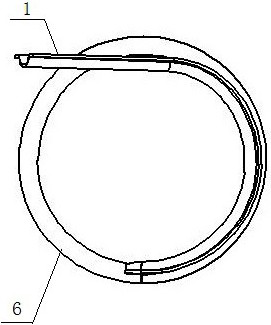

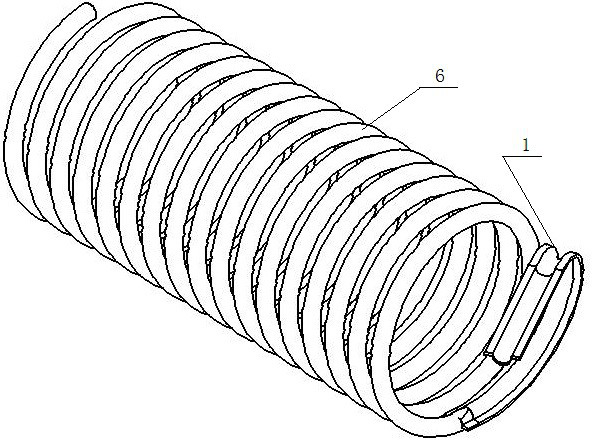

[0028] combine Figure 1-Figure 6 As shown, this adjustable resistance knob maintenance method uses the sliding head guide 1 to slide the resistance core 7 onto the resistance coil 6. Guide smoothly onto the coil.

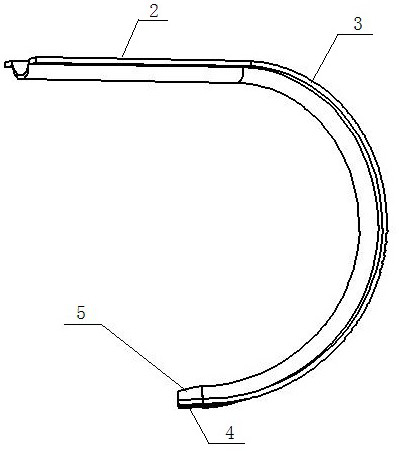

[0029] refer to Figure 4 , Figure 5 , the sliding head guide 1 is composed of a sliding head guide handle 2, a sliding head gap track 3, and a buffer protection connector 4. The sliding head guide handle 2 is provided with an arc-shaped groove along the length direction, and the arc-shaped groove protrudes upwards, and the arc-shaped Edges are arranged on both sides of the notch of the groove along the length direction. The slider gap track 3 is an arc-shaped body formed by bending another arc-shaped groove with edges. One end of the slider gap track 3 is fixed with the slider guide handle 2. Slide The other end of the head gap track 3 is spliced to fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com