Method and device for detecting engine oil adaptability

A detection method and an adaptable technology, applied in the field of oil adaptability detection methods and devices, can solve problems such as inability to accurately evaluate oil, inability to truly reflect the actual impact of oil volatilization, etc., so as to avoid excessive emission and oxygen sensor poisoning and modification steps Simple, low-impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

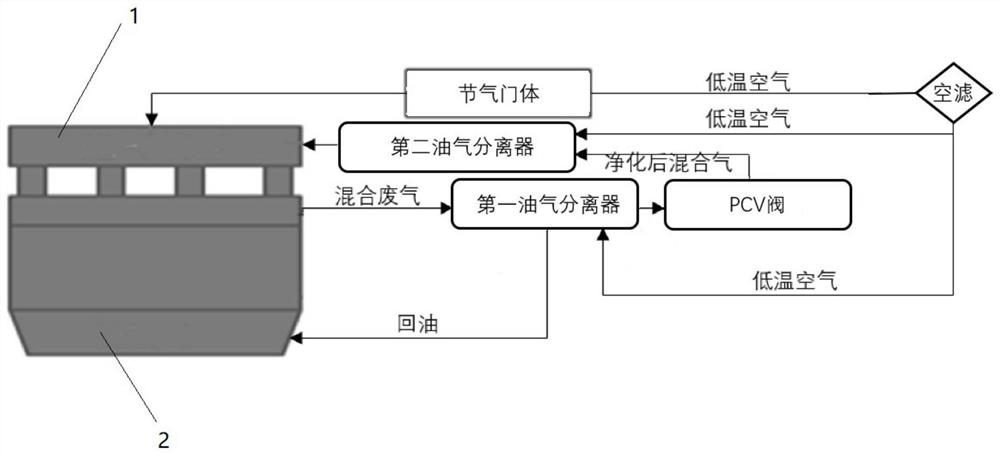

[0040] Refer to attached figure 1 , an engine oil adaptability detection device provided in an embodiment of the present invention includes an air filter (hereinafter referred to as air filter), an engine, an oil-air separation system and a second oil-air separator, and the engine includes a crankcase and an intake manifold Pipe 1, the oil-gas separation system includes a first oil-gas separator and a PCV valve, the air filter is respectively connected to the first oil-gas separator and the second oil-gas separator through pipelines, the crankcase, the first oil-gas separator The device, the PCV valve, the second oil-gas separator and the intake manifold 1 are connected in sequence.

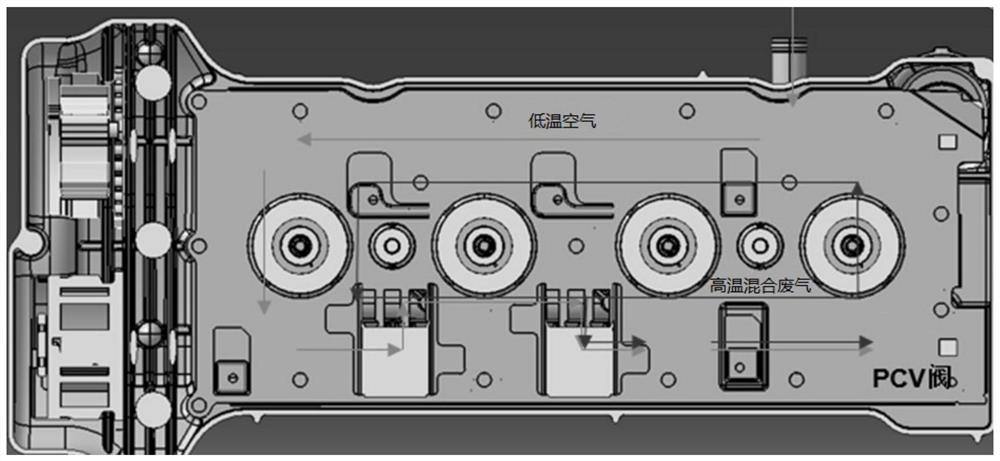

[0041] as attached figure 2 As shown, the first oil-gas separator is a cylinder head cover integrated labyrinth oil-gas separator, and the first oil-gas separator includes a first air inlet, a first oil outlet and a first exhaust port. The incoming low-temperature air enters the first oil-air ...

Embodiment 2

[0045] A method for detecting engine oil adaptability provided by an embodiment of the present invention includes the following steps:

[0046] 1) A second oil-gas separator is connected between the oil-gas separation system of the vehicle and the intake manifold 1, the second oil-gas separator is detachable, the vehicle is a methanol vehicle, and the engine oil used by the methanol vehicle is methanol oil;

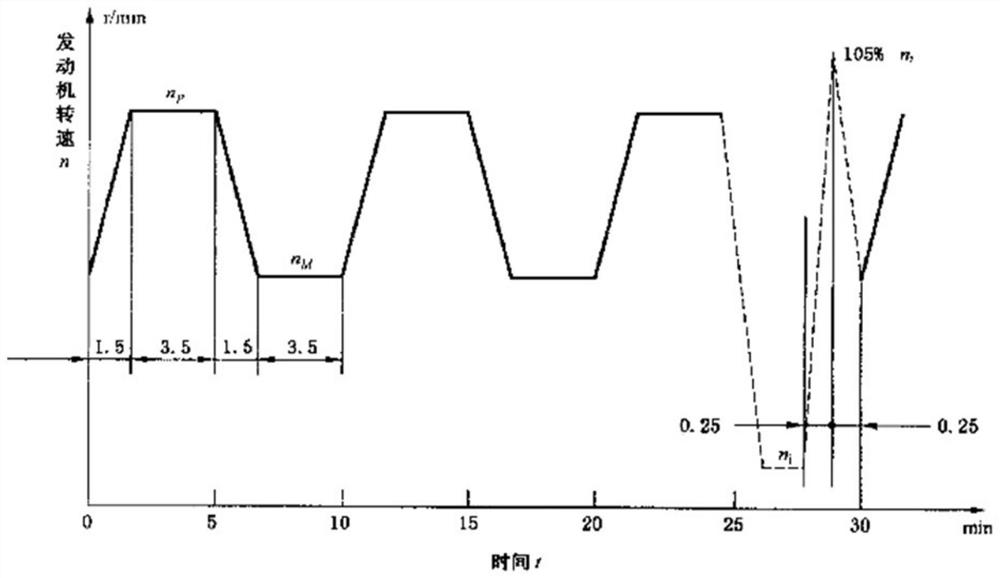

[0047] 2) According to the alternating load test specification in the GB / T 19055 standard, carry out a 50-100h cycle test on the vehicle, and each cycle runs for 30 minutes. The specific operation is as follows: image 3 Shown (solid line means full throttle):

[0048] a. Fully open the throttle, from the speed of maximum net torque (n M ) rises evenly to the speed of maximum net power (n P ), which lasted 1.5min; at n P Run stably for 3.5 minutes; then drop to n evenly M , which lasted 1.5min; at n M Stable operation for 3.5min. Repeat the above alternating workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com