A Method for Realizing Vertical Take-off and Landing and Horizontal Flight with Segmented Bottom Drive Type Wing

A vertical take-off and landing, plate-wing technology, applied to vertical take-off and landing aircraft, aircraft, transportation and packaging, etc., can solve the problems of not smooth and natural vertical take-off and landing mode conversion, divergence of chord blowing airflow, and insufficient vertical lift. To achieve the effects of no sudden change in the control effect, smooth changes in control parameters, and improved flight efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

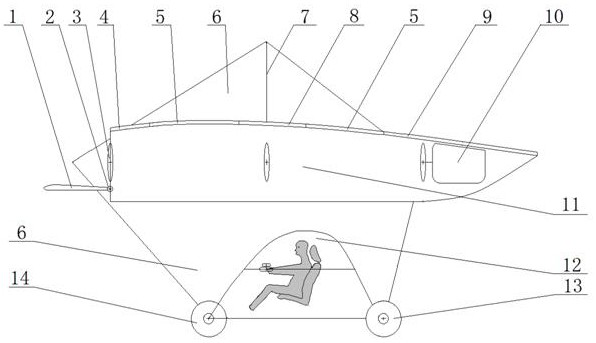

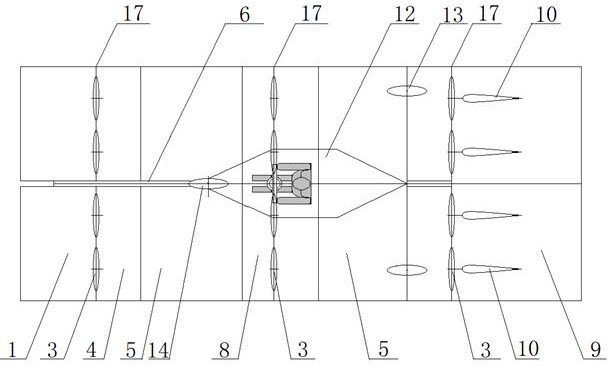

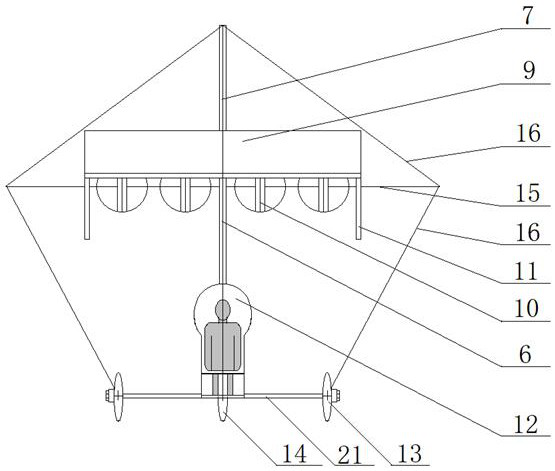

[0040] Embodiment 1: as Figure 1-19 Shown, the method that the present invention realizes vertical take-off and landing and horizontal flight with segmented bottom drive type plate wing is: adopt the sheet fuselage (the height-to-width ratio of fuselage is 5) aircraft of large-area plate-shaped wing for wing , the large-area plate-shaped wing is designed as a combined type, and it is divided into three sections of movable strip-shaped wings and two sections of fixed strip-shaped wings along the transverse direction. The movable strip-shaped wings and fixed strip-shaped wings are arranged alternately like zebra crossings. Through the tilting of the movable strip-shaped wing, the movable strip-shaped wing and the fixed strip-shaped wing can be combined into an integral plate-shaped wing to adapt to horizontal flight, and the movable strip-shaped wing can be opened laterally like a shutter A strip-shaped air intake hole is formed to realize vertical take-off and landing; a secti...

Embodiment 2

[0047] Embodiment 2: as Figure 1-19 As shown, the method for realizing vertical take-off and landing and horizontal flight of the present invention with segmented bottom-driven plate wings is the same as that of Embodiment 1. The wings of the aircraft adopt large-area combined plate-shaped wings, and the fuselage adopts an aspect ratio of 6. sheet body. The large-area plate-shaped wing is divided into 5 sections of movable strip-shaped wings and 4 sections of fixed strip-shaped wings along the transverse direction, and 3 sections of activities are set between the frontmost movable strip-shaped wing and the rearmost movable strip-shaped wing. The strip-shaped wing and 4 fixed strip-shaped wings, the bottom of each movable strip-shaped wing is fixed side by side with a group of jet engine driving devices, the distance between two adjacent groups of driving devices (that is, two adjacent The distance between the movable strip-shaped wings) is greater than 6 times the diameter D...

Embodiment 3

[0048] Embodiment 3: as Figure 1-19 As shown, the method for realizing vertical take-off and landing and horizontal flight of the present invention with segmented bottom-driven plate wings is the same as that of embodiment 1. The wings of the aircraft adopt large-area combined plate-shaped wings, and the fuselage adopts an aspect ratio of 4. sheet body. The large-area plate-shaped wing is divided into 8 sections of movable strip-shaped wings and 7 sections of fixed strip-shaped wings along the transverse direction, and 6 sections of activities are set between the frontmost movable strip-shaped wing and the rearmost movable strip-shaped wing. Strip-shaped wings and 7 sections of fixed strip-shaped wings, a group of 10 propeller drive devices are fixed side by side under each movable strip-shaped wing, and the distance between two adjacent sets of drive devices (that is, two adjacent movable The distance between the strip-shaped wings) is greater than 10 times the diameter D o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com