Lactase-containing double microcapsule, preparation method therefor, and use thereof

A lactase and microcapsule technology, which is applied to the double microcapsules containing lactase, its preparation and application fields, can solve problems such as lactase microencapsulation has not been carried out, achieves the solution of lactose intolerance and improves microencapsulation. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0128] Preparation of Double Microcapsules of Lactase

[0129] Ⅰ. Materials and methods

[0130] 1. Materials and Reagents

[0131] 1) Material

[0132] (1) Core material

[0133] Godo YNL-2 (Godo Shusei Co., Ltd., Tokyo, Japan) was used as lactase. The enzyme is derived from Kluyveromyces lactis with an activity of 7,448 units / g. Herein, 1 unit is defined in such a way that 1 μmol of o-nitrophenyl-β-D-galactopyranoside (ONPG) is decomposed into o-nitrophenol and D-galactose per minute.

[0134] (2) Coating material

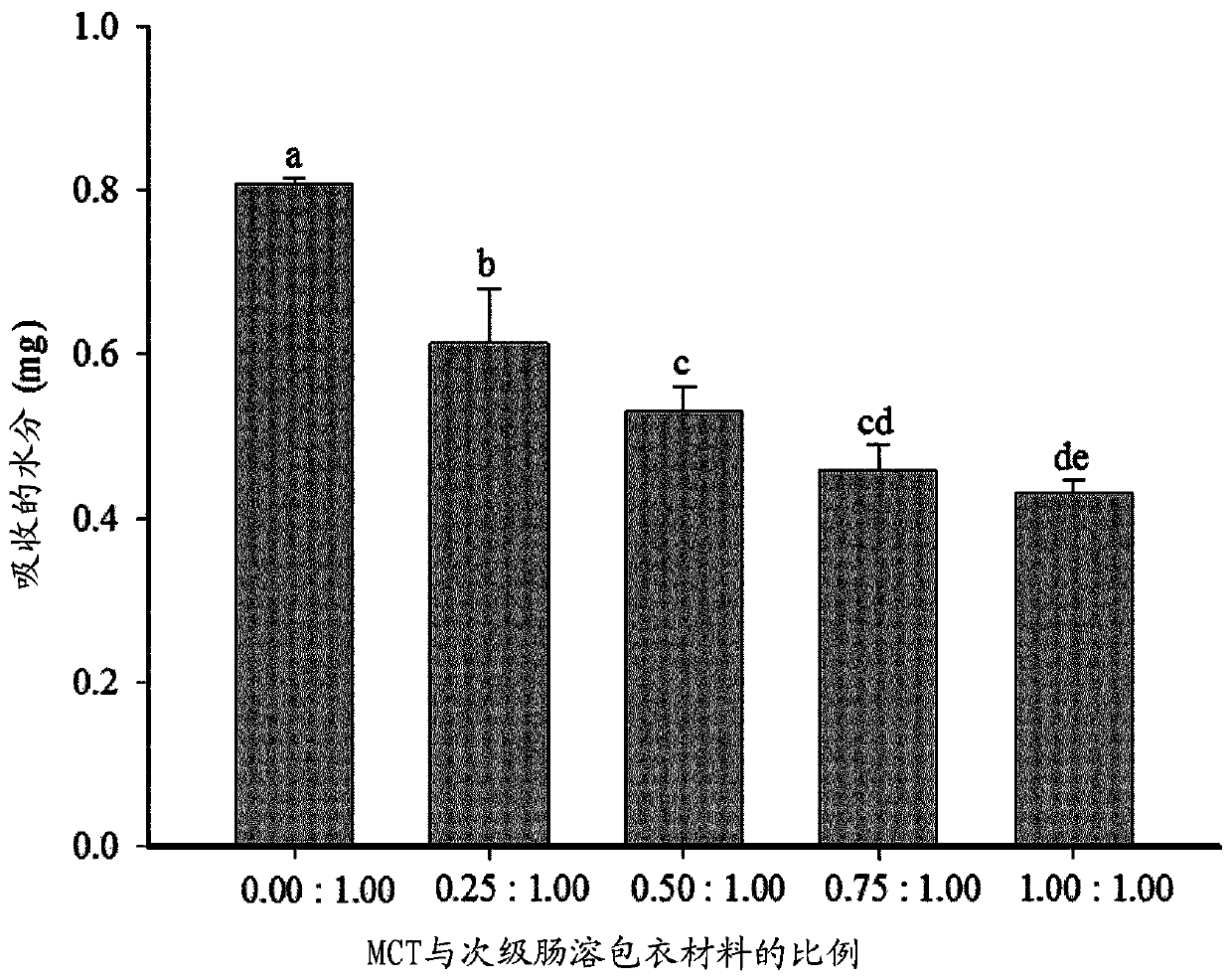

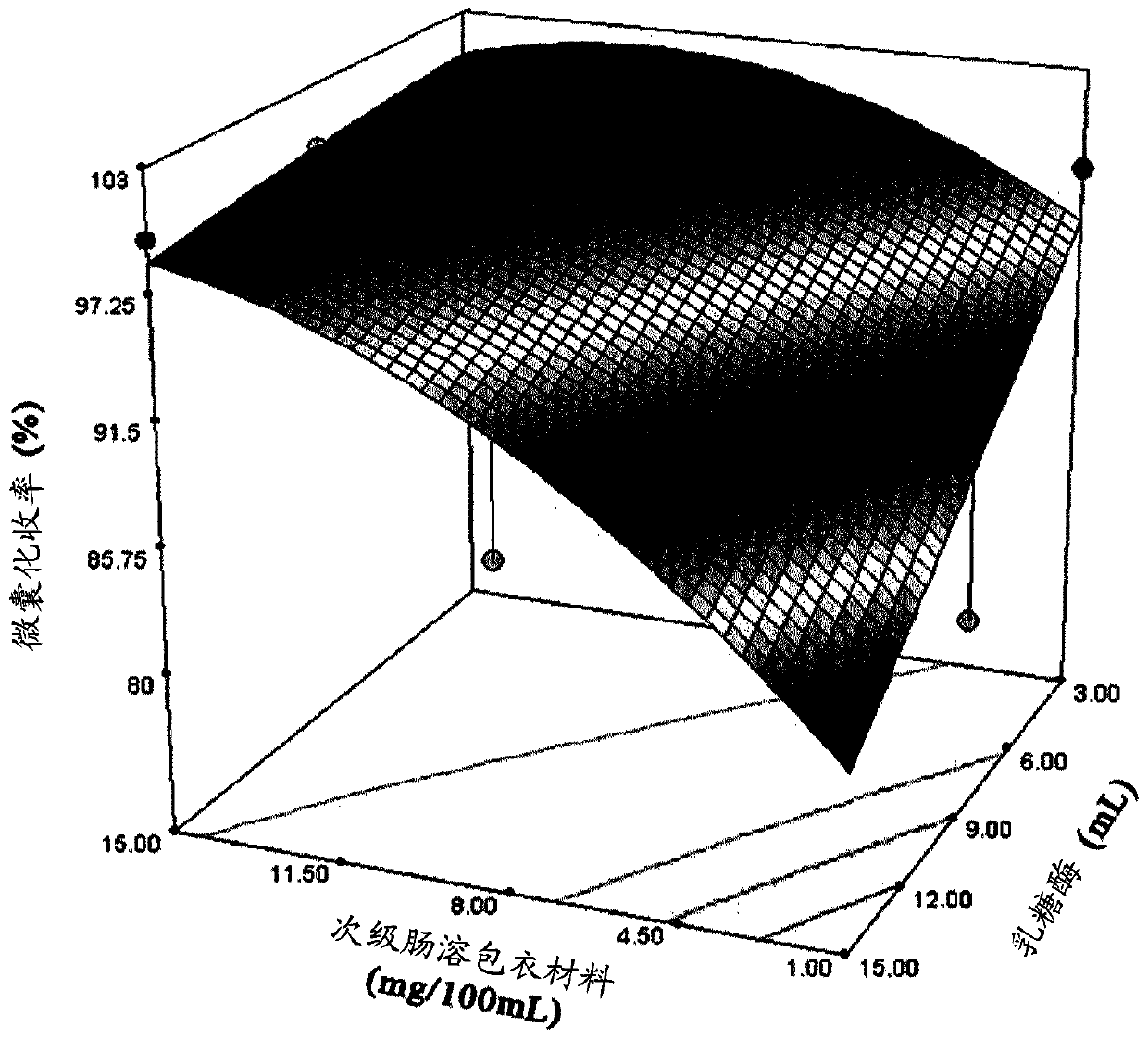

[0135] Medium-chain triglyceride (MCT) as a primary coating material was purchased from Wellga Co., Ltd. (Seongnam, Korea). HPMCP, shellac and zein as secondary coating materials were purchased from Samsung FineChemicals Co., Ltd., Shellac Korea Co., Ltd. and Richwood Trading (Pooglimmuyark) Co., Ltd. .

[0136] (3) Emulsifier

[0137] Polyglycerol polyricinoleate (PGPR; HLB 0.6) and polyoxyethylene sorbitan monolaurate (PSML; HLB 16.7) were food additive...

Embodiment 1

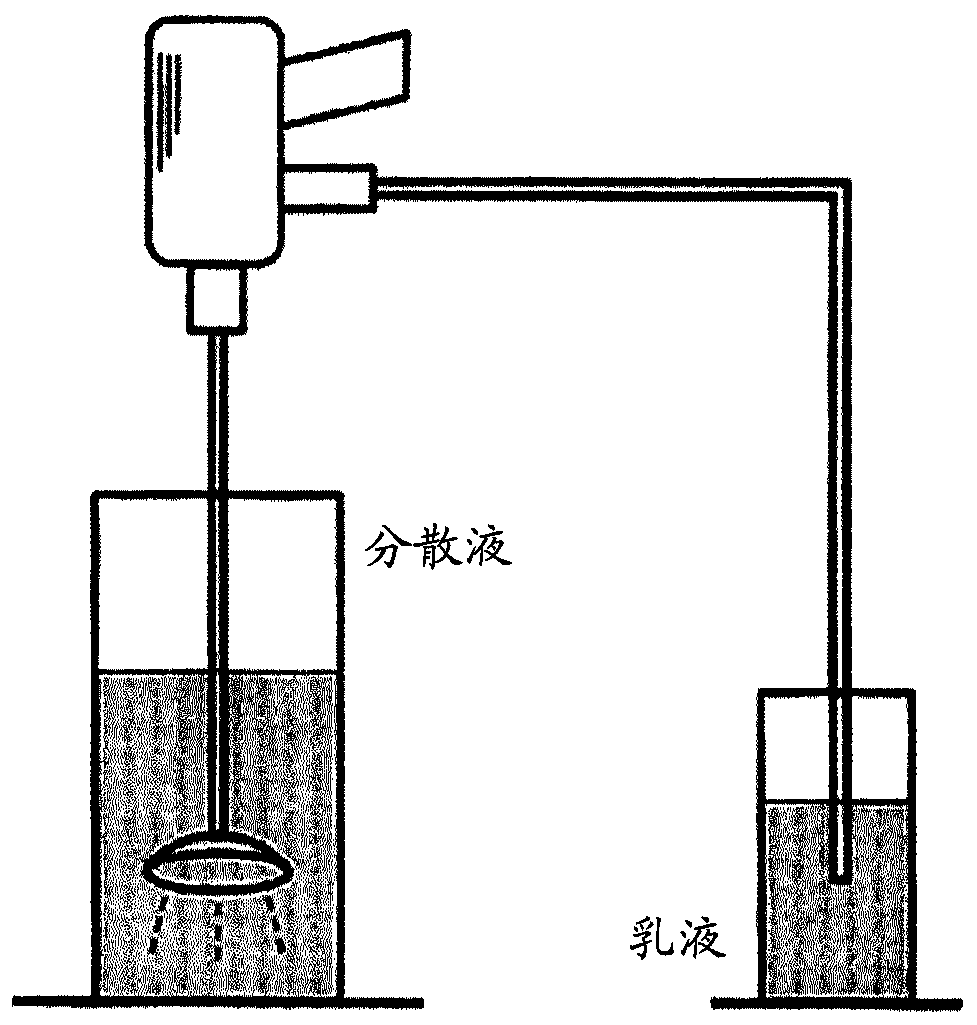

[0251] An emulsion of lactase was obtained by providing lactase as core material and mixing the core material with medium-chain triglyceride (MCT) as primary coating material and as primary emulsifier with an HLB value of 0.6 and a concentration of 1.0%. The polyglycerol polyricinoleate (PGPR) was stirred together at 60° C. and 1500 rpm for 30 minutes to obtain a pre-emulsion, which was then stirred at 60° C. and 9000 rpm for 2 minutes.

[0252] At this time, the core material and the primary coating material were mixed in a ratio of 1:3 (v / v), and the core material and the primary emulsifier were mixed in a ratio of 1:3 (v / v), followed by stirring.

[0253] Then, a double microcapsule emulsion of lactase was obtained by providing an emulsion of lactase as a core material, and combining the emulsion of lactase with HPMCP (Samsung Precision Chemical Co., Ltd.) as a secondary coating material and PSML with an HLB value of 16.7 and a concentration of 1.0% was stirred together at ...

Embodiment 2

[0258] Lactase-containing double microcapsules were prepared according to the same procedure as described in Example 1, except that shellac (Shellac Korea Co., Ltd.) was used instead of HPMCP as the secondary coating material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com