Design method of high-speed railway saline soil embankment partition based on salt-frost heave double control

A high-speed railway and saline soil technology, applied in the field of geotechnical engineering, can solve problems such as the design theory of high-speed railway saline soil embankment partitions that have not yet been clarified, and achieve a clear implementation process, strong operability, simple and fast operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

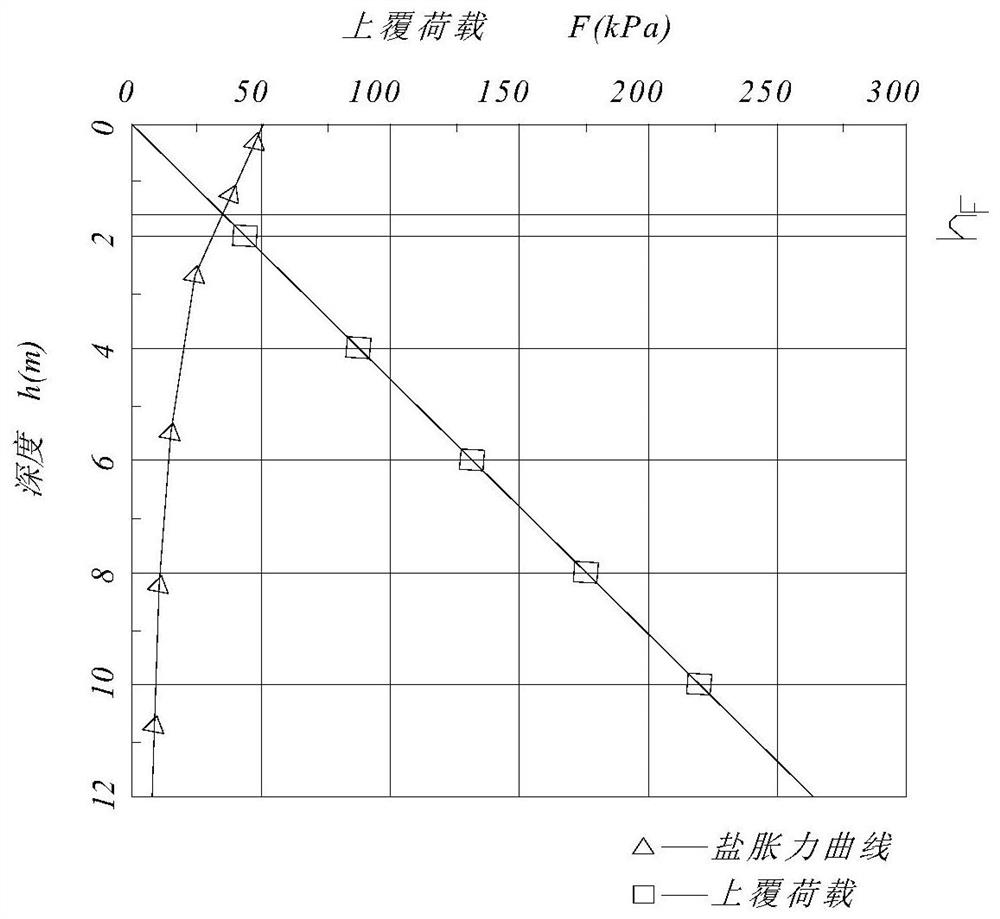

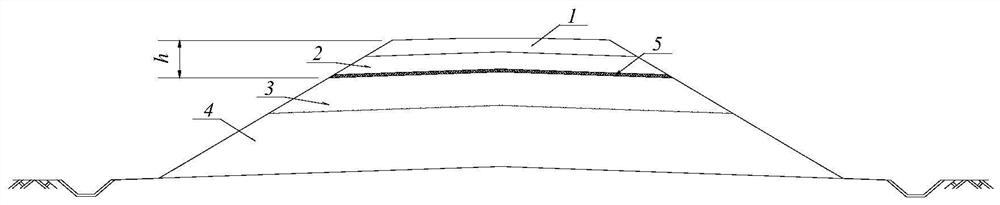

[0037] A high-speed railway ballastless track subgrade in a saline soil area has a filling height of 5m, a top surface width of 13.6m, and a side-slope ratio of 1:1.5. In order to avoid salt swelling, frost heaving and subgrade salinization during the design of the subgrade In order to effectively prevent salt-frost heave deformation and salinization diseases, it is necessary to set up a partition layer for the subgrade bed of the high-speed railway, and a special partition layer should be designed to effectively prevent salt-frost heave deformation and salinization. Adopt the method of the present invention to determine the partition layer setting position of this coarse-grained saline soil high-speed railway embankment, concrete steps are as follows:

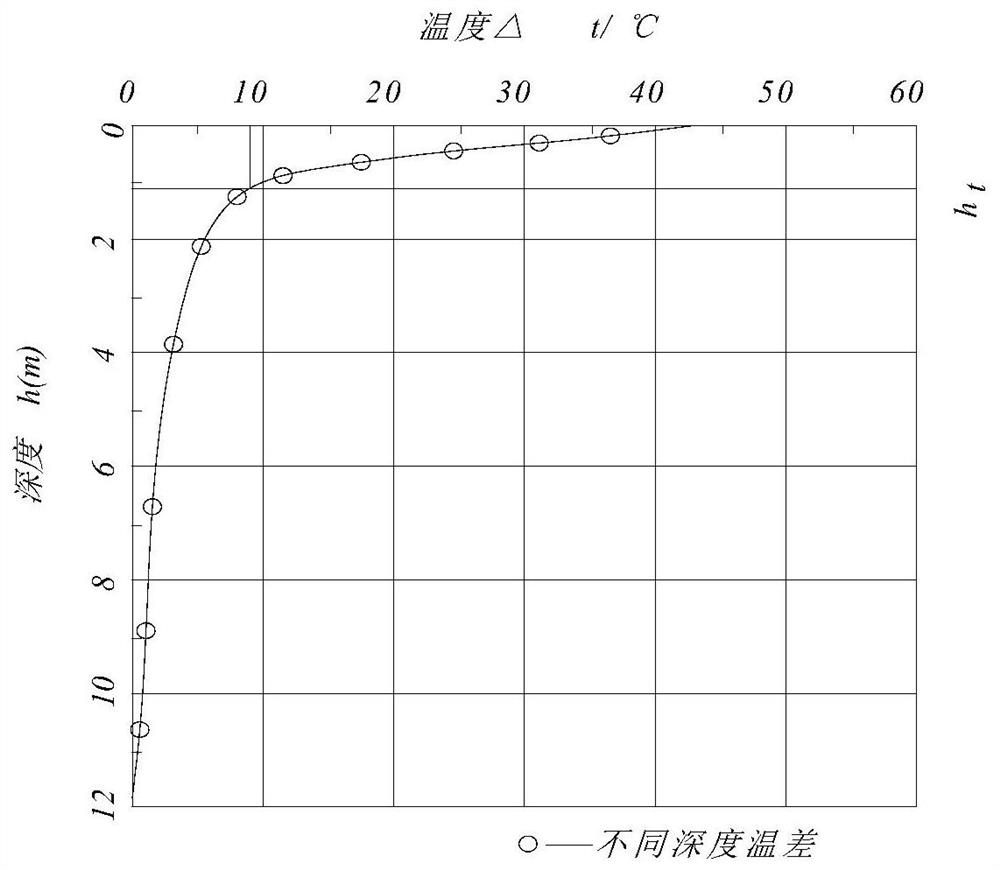

[0038] (1) Through on-site in-situ monitoring, determine the temperature difference Δt at different depths h below the top surface of the saline soil subgrade with a duration of not less than one year, and draw a Δt-h diagram w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com