A detection method for the coaxiality of the optical path of the laser output head

A detection method and output head technology, applied in the direction of testing optical performance, etc., can solve the problems of difficult beam, increase the difficulty of operation, affect the heating of the laser nozzle, etc., and achieve the effect of improving efficiency, saving time, and avoiding blind adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] This embodiment is a detection method for the coaxiality of the optical path of the laser output head, which includes the following steps:

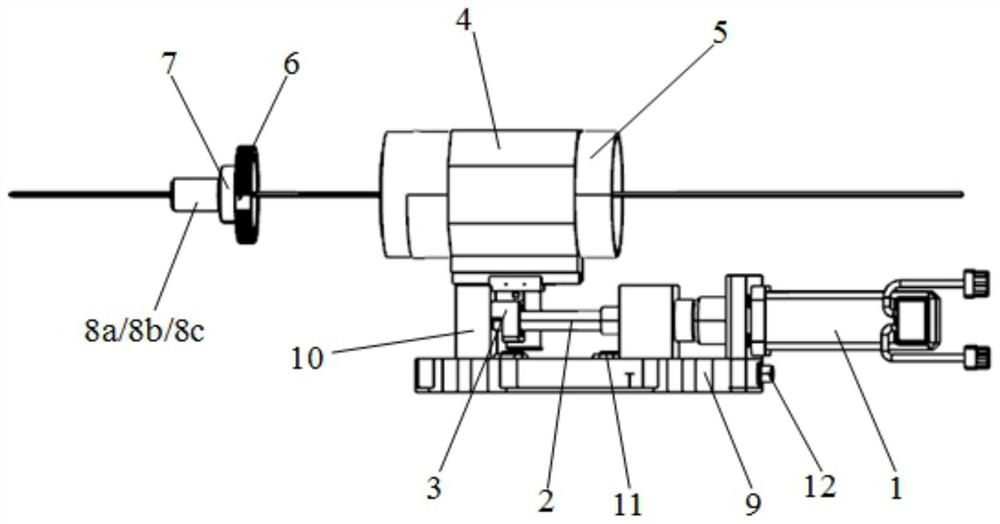

[0026] 1) Please refer to figure 1 , to obtain a laser output head to be detected, which includes a servo motor 1, a screw 2 driven by the servo motor 1 to rotate, a screw nut 3 that moves on the screw rod 2, and a screw nut 3 that is fixedly connected to the screw nut 3. The support base 4, the lens barrel assembly 5 fixed on the support base 4, the nozzle knob 6 located on the optical path, and the nozzle base 7 fixed on the nozzle knob 6;

[0027] The laser output head also includes a base plate 9, a support module 10 arranged on the base plate 9 and supporting the screw mandrel 2, and a limit switch 11 arranged on the base plate 9 to limit the upper limit position and the lower limit position of the lens barrel assembly 5; the base plate 9 A signal interface 12 is arranged on it;

[0028] 2) Control the servo motor 1 to drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com