A multidirectional stabilizer

A stable and spreader technology, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of wasting installation time, the lifting adjustment of parts that cannot be lifted by the spreader, and the rapid installation of unfavorable equipment, so as to save installation and assembly time , Improve the efficiency of installation and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following content describes the specific implementation manner of the present invention in detail in conjunction with the accompanying drawings.

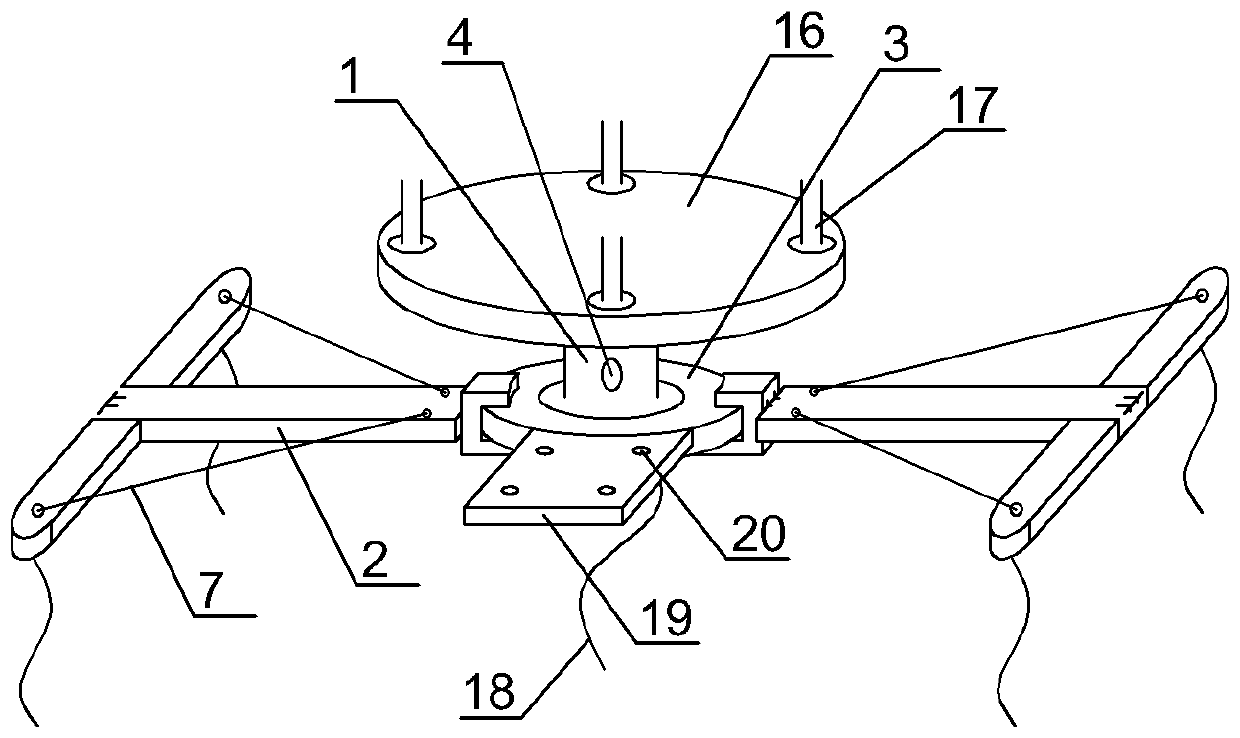

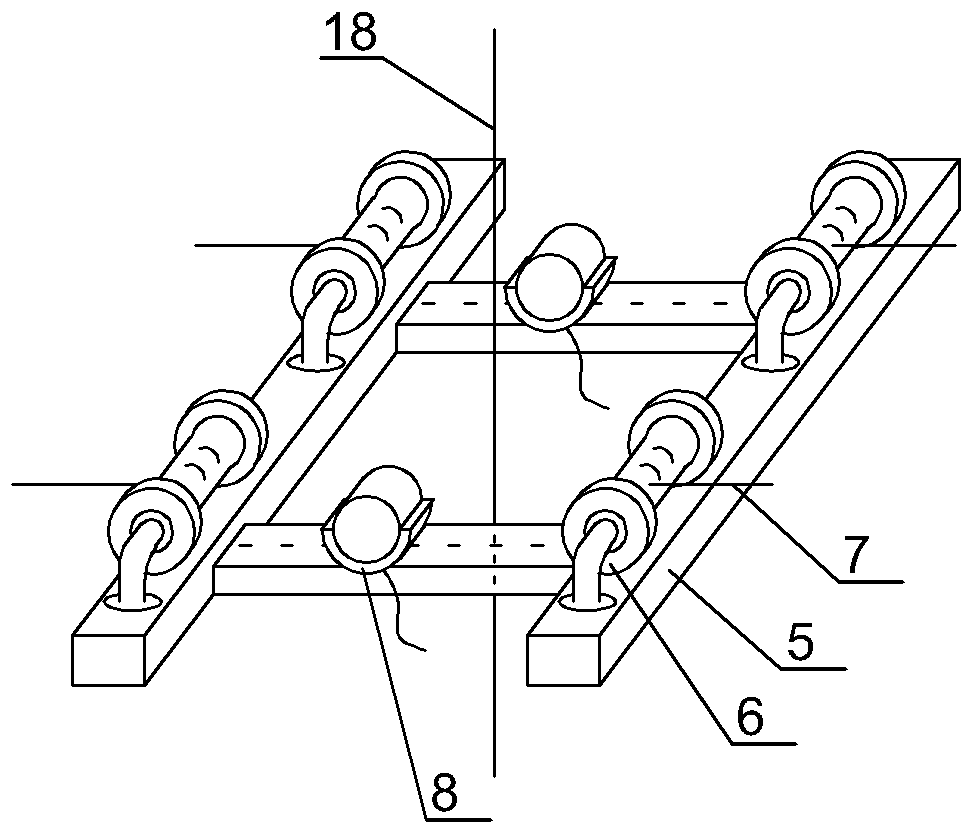

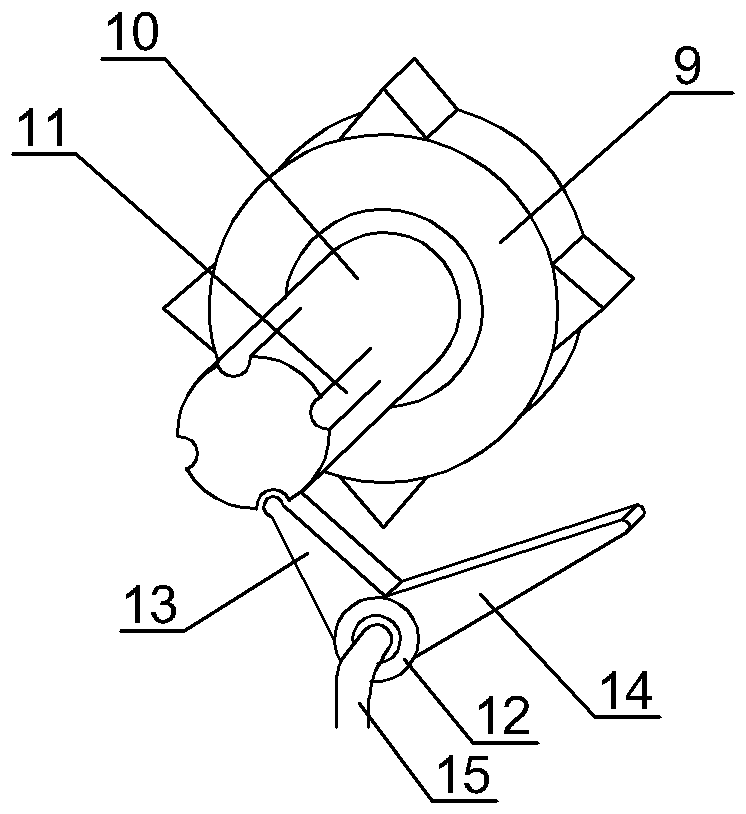

[0016] A multi-directional stable sling, comprising a lifting main body 1, a boom main body 2 and a multi-directional stable main body 3, characterized in that a lifting socket 4 that can be inserted into a lifting motor shaft is provided on the front wall of the lifting main body 1 , the lifting main body 1 is rotatably embedded in the multi-directional stable main body 3, the multi-directional stable main body 3 is provided with an operating bracket 5, and each of the four corresponding directions of the operating bracket 5 is provided with a multi-directional stable The spool 6, the multidirectional stable spool 6 is wound with a stable pulling wire 7, the left and right sides of the multidirectional stable main body 3 are provided with a boom main body 2, and the boom main body 2 is provided with several perforation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com