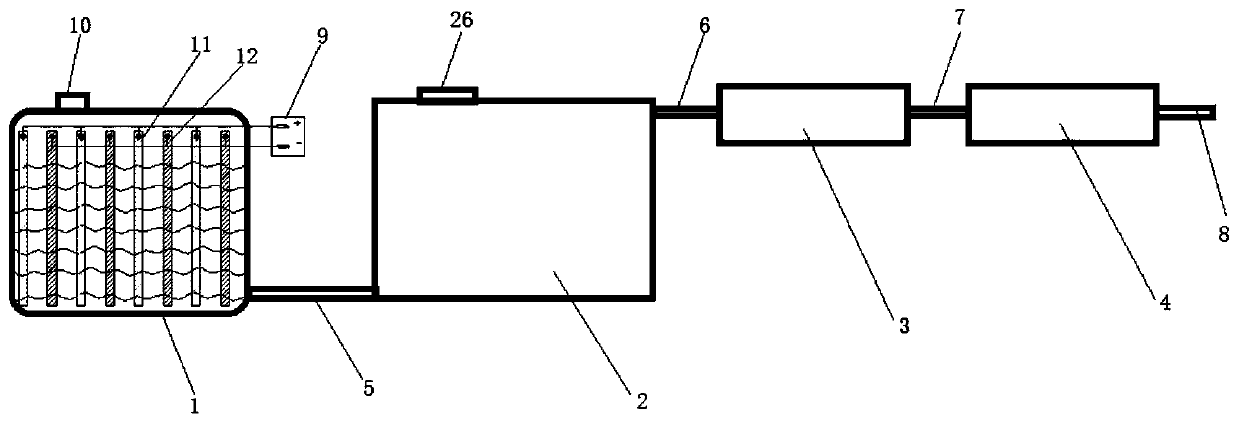

Feces wastewater treatment equipment

A fecal sewage and treatment equipment technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of long aerobic fermentation treatment time and harsh temperature requirements, and achieve Avoid use, high bacteria killing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] NaOH aqueous solution is used as the electrolyte, and the concentration of the electrolyte is 14mol / L.

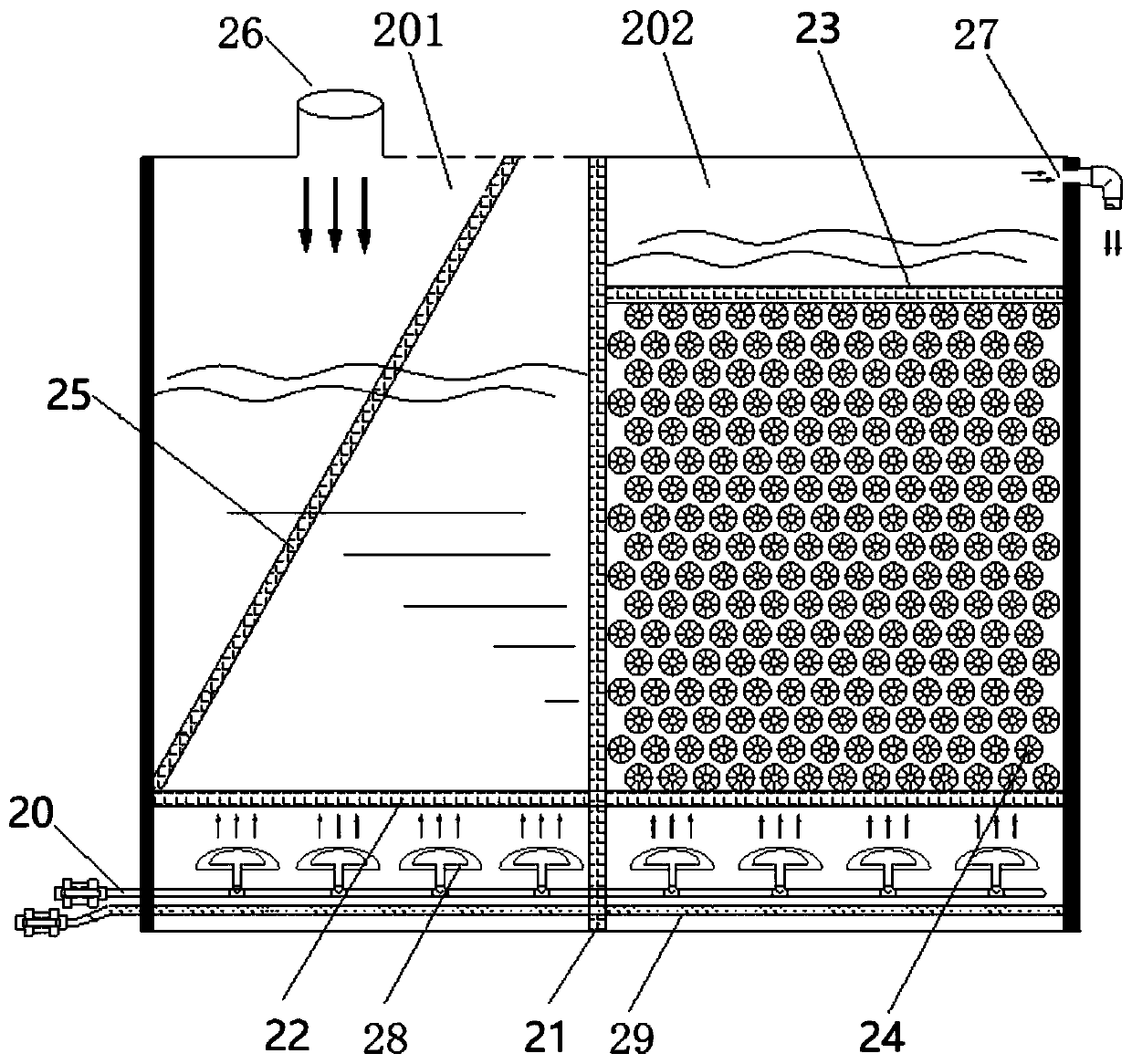

[0059] The sinusoidal alternating current with a frequency of 50Hz is used as the power supply, and the iron anode and graphite cathode are used for electrolysis, and the current density is 88mA / cm 2 , The electrolysis temperature is 30°C-60°C. Electrolysis can be done in air environment. The electrolysis time may be 60 minutes. The current density can be adjusted by a current density regulator, and the electrolysis temperature can be adjusted by a heat exchanger in the curing agent preparation chamber 1 .

[0060] The electrolyzed solution contains an oxidant, and the electrolyzed solution is sent into the septic tank, or the sewage containing feces in the septic tank is lifted to the oxidation chamber 2, and the electrolyzed solution is sent into the oxidation chamber. The reaction temperature can be adjusted through the second heat exchanger in the oxidation ch...

Embodiment 2

[0063] NaOH aqueous solution is used as the electrolyte, and the concentration of the electrolyte is 14mol / L.

[0064] The sinusoidal alternating current with a frequency of 50Hz is used as the power supply, and the iron anode and graphite cathode are used for electrolysis, and the current density is 88mA / cm 2 , The electrolysis temperature is 30°C-60°C. Electrolysis can be done in air environment. The electrolysis time may be 60 minutes.

[0065] The electrolyzed solution contains an oxidant, and the electrolyzed solution is sent into the septic tank, or the sewage containing feces in the septic tank is lifted to the oxidation chamber, and the electrolyzed solution is sent into the oxidation chamber.

[0066] During the reaction, the concentration of the oxidizing agent in the feces-containing sewage is preferably 7 mol / L, and the reaction lasts for 7 minutes. In this embodiment, 99% of coliform bacteria and 97% of viable bacteria are removed; the bactericidal effect on Es...

Embodiment 3

[0068] NaOH aqueous solution is used as the electrolyte, and the concentration of the electrolyte is 14mol / L.

[0069] The sinusoidal alternating current with a frequency of 50Hz is used as the power supply, and the iron anode and graphite cathode are used for electrolysis, and the current density is 88mA / cm 2 , The electrolysis temperature is 30°C-60°C. Electrolysis can be done in air environment. The electrolysis time may be 60 minutes.

[0070] The electrolyzed solution contains an oxidant, and the electrolyzed solution is sent into the septic tank, or the sewage containing feces in the septic tank is lifted to the oxidation chamber, and the electrolyzed solution is sent into the oxidation chamber.

[0071] During the reaction process, the concentration of the oxidant in the feces-containing sewage is preferably 7 mol / L, the reaction lasts 7 minutes, and the reaction temperature is 15-30° C. In the present embodiment, 99% of coliform bacteria and 97% of viable bacteria a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com