Anti-wrinkling press roller

A pressure roller and anti-wrinkle technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of no structure, wrinkling, coil discounting, etc., and achieve the effect of eliminating creases or wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

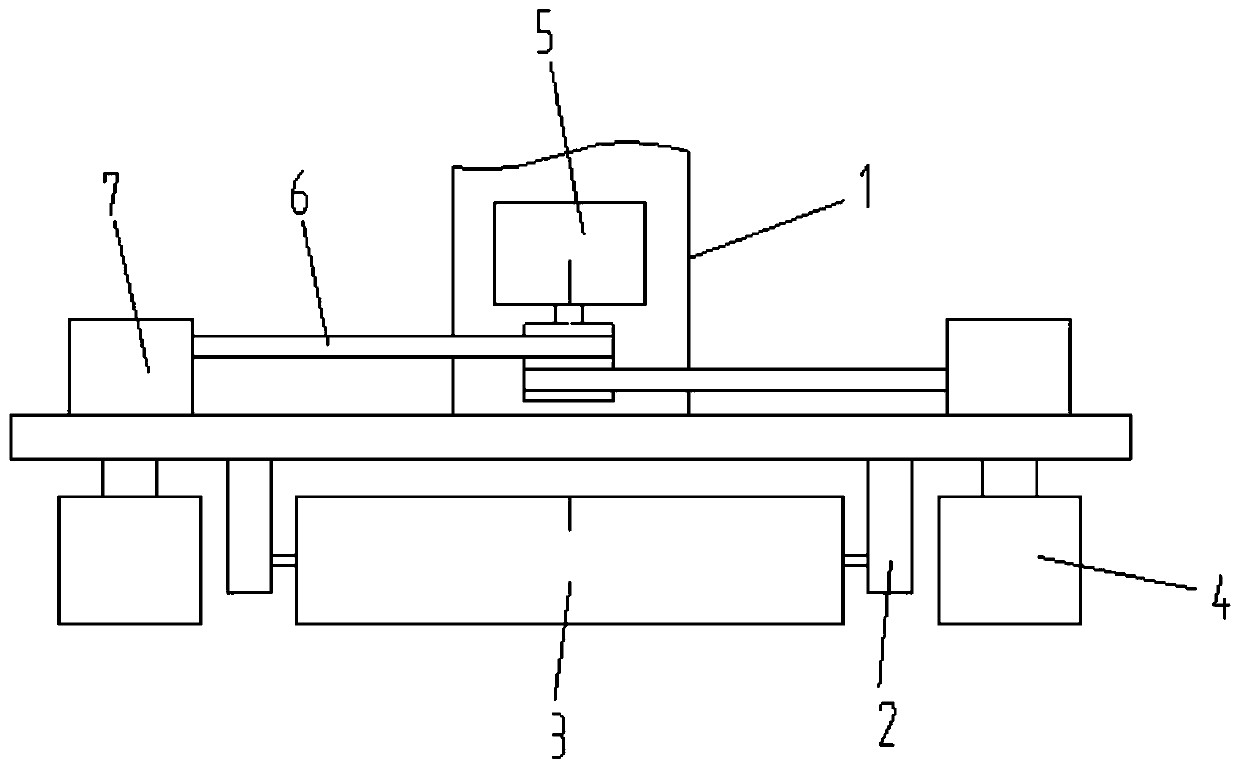

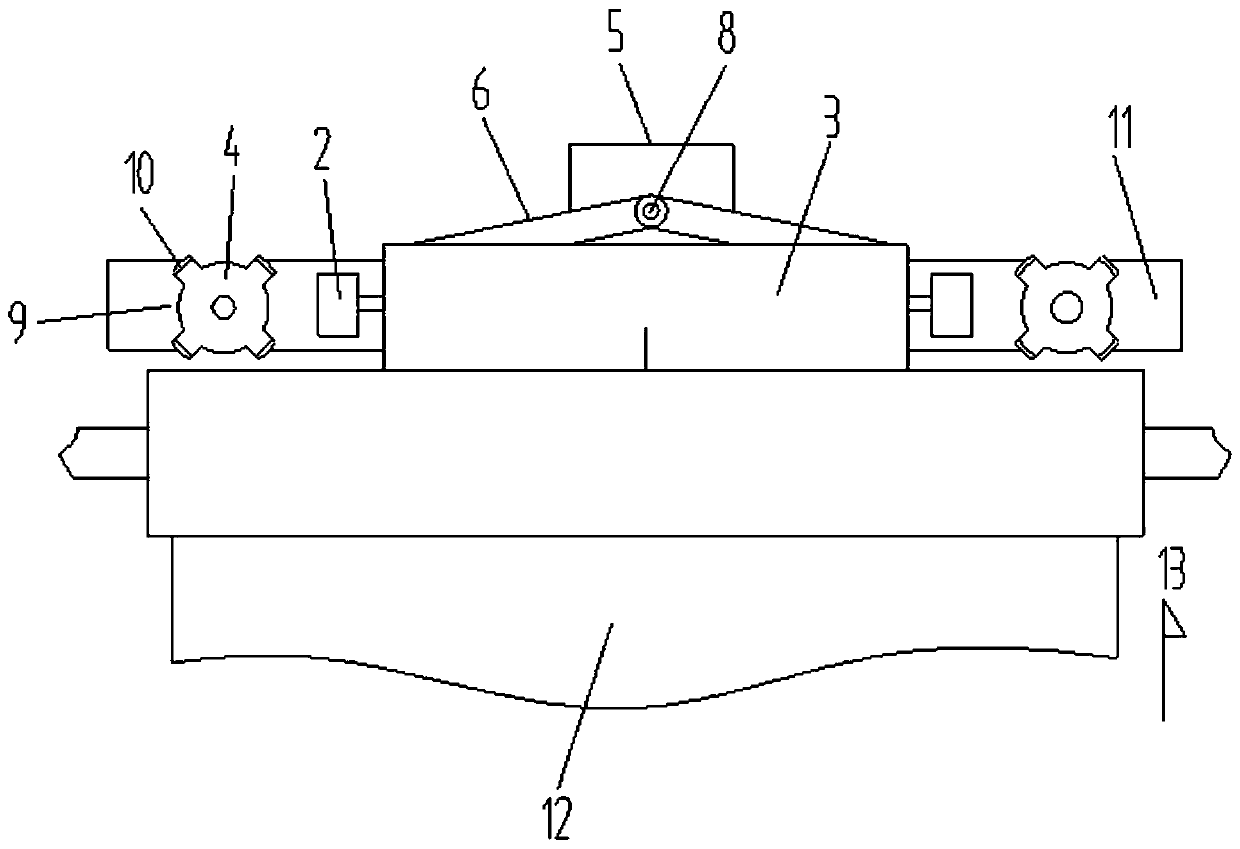

[0020] Anti-crease pressing roller of the present invention, as figure 1 , 2 As shown, it includes a U-shaped bracket 1, and a pressure roller 3 is arranged in rotation between two arms 2 arranged in parallel on the bracket 1, and two friction wheels 4 are also arranged on the support plate 11 connecting the two arms 2. The friction wheels 4 are arranged on both sides of the pressure roller 3, along the direction of the coiled material 12 under the pressure roller, the friction wheel 4 on the left side can rotate in the clockwise direction, and the friction wheel 4 on the right side can rotate in the counterclockwise direction;

[0021] When any point on the outer wall of the friction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com