Stiffness identification system and identification method of industrial robot based on six-dimensional virtual joint model

An industrial robot and joint model technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problem of complex implementation of stiffness identification experiments, affecting the control accuracy and control performance of industrial robots, and measurement data that cannot fully reflect changes in industrial robot stiffness, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

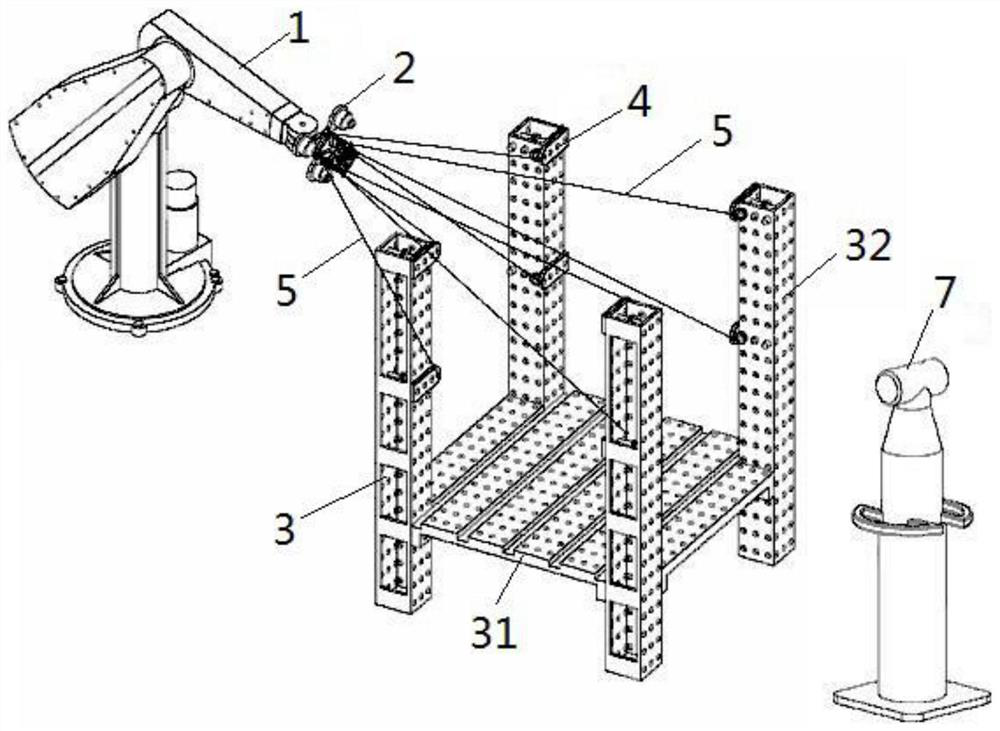

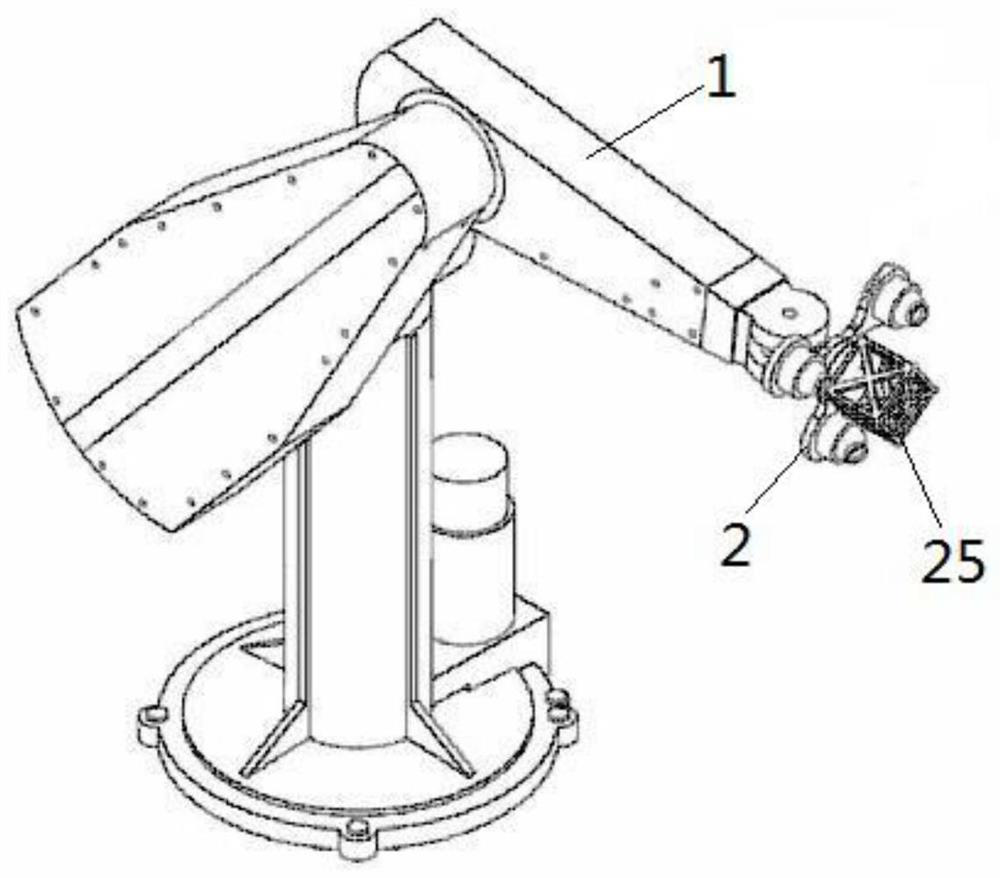

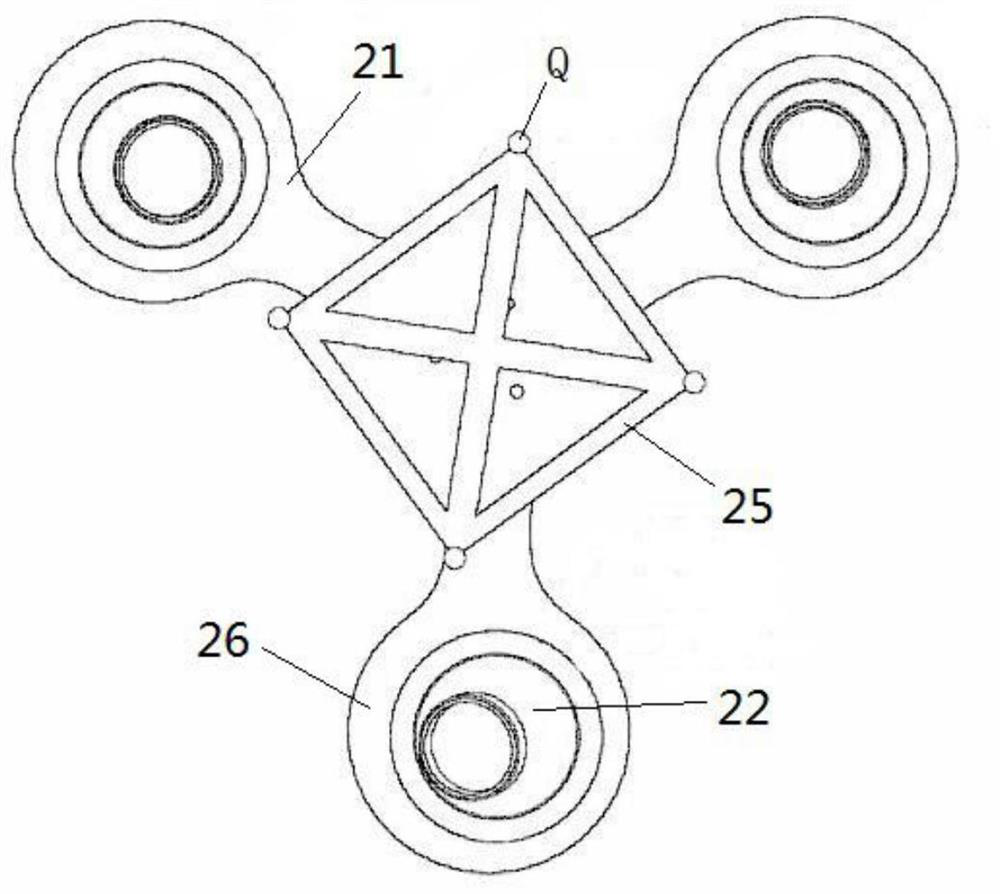

[0041]The reference signs are: connecting ball Q, industrial robot 1, six-dimensional force measuring tool 2, target ball fixing plate 21, installation hole 21a, center plate 211, target ball plate 212, target ball 22, six-dimensional force sensor 23 , sensor adapter plate 24, load force loading tool 25, bolt hole 25a, hollow cavity 25b, target ball base 26, load force loading device 3, mounting plate 31, hollow column 32, cavity 32a, force loading direction converter 4. Lasso guide plate 41, lasso pulley 42, lasso direction offset projection 43, pulley support shaft 44, load pulley 45, lasso 5, weight 6, laser tracker 7.

[0042] Figure 1 to Figure 10 It is a schematic structural diagram of the present invention. As shown in the figure, the industrial robot stiffness identification system based on the six-dimensional virtual joint model of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com