Rotary dough molding machine

A forming machine, rotary technology, applied in dough forming and cutting equipment, dough embossing machines, dough slitting machines, etc., can solve problems such as poor alignment, contamination of dough parts, and difficulty in meeting hygiene standards, and achieve the most Best alignment, high hygiene standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

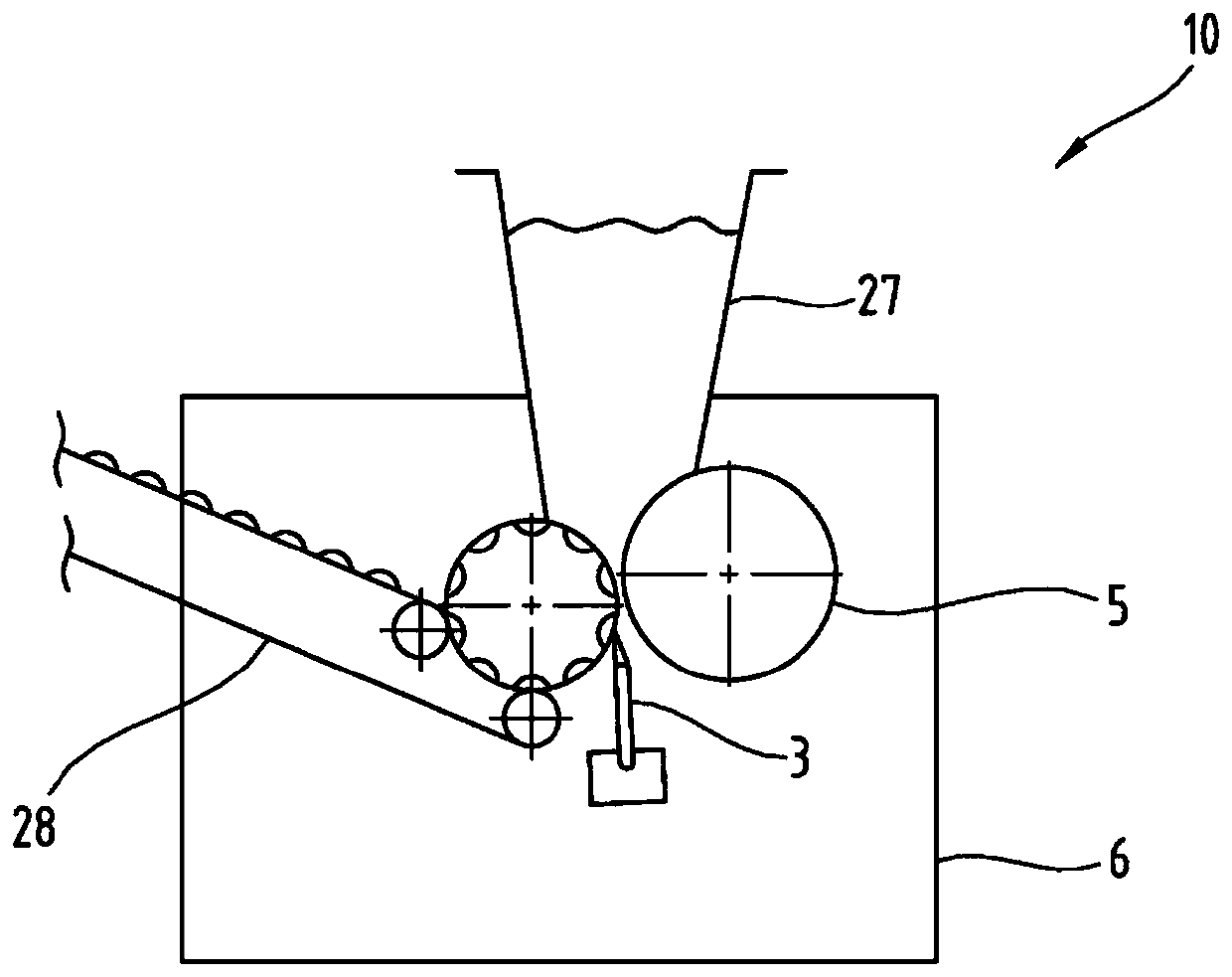

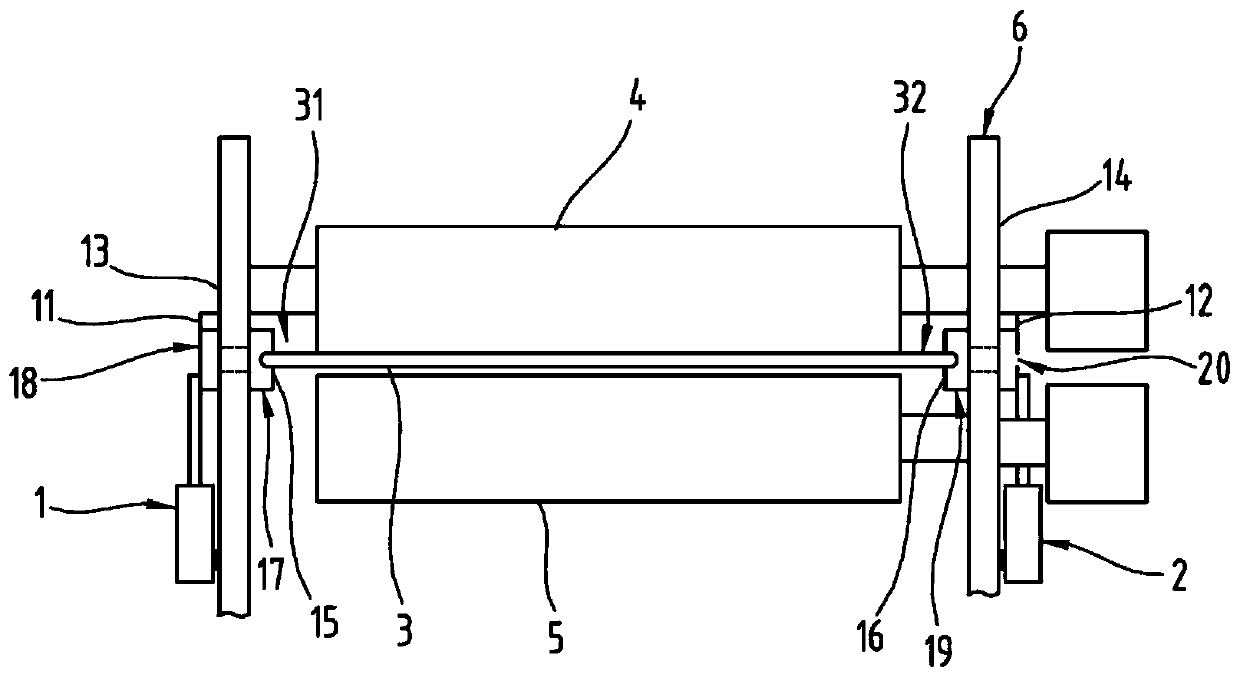

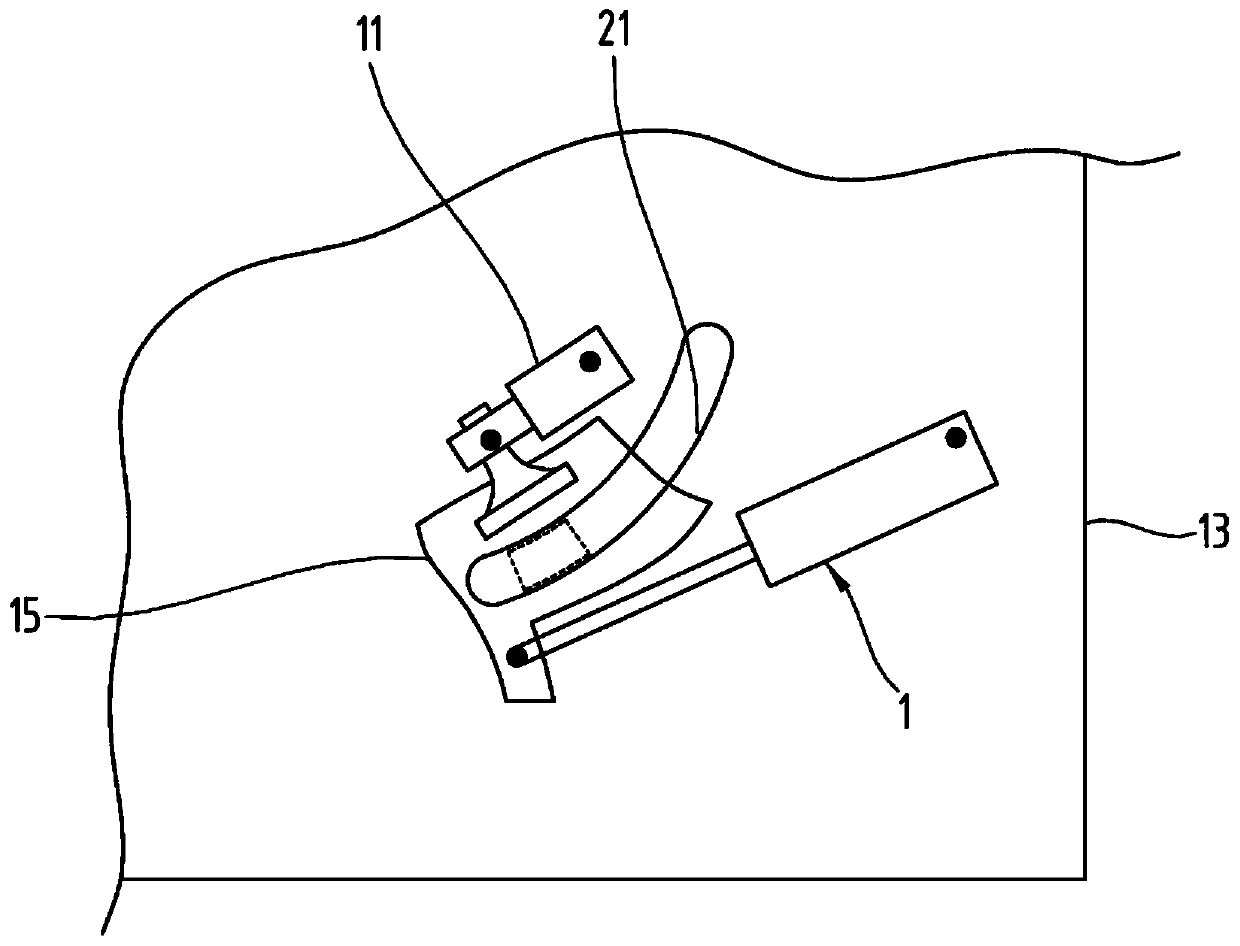

[0042] figure 1 Illustrated is a rotary dough forming machine 10 comprising a frame 6, a molding roll 4 and a feed roll 5 each rotatably mounted about a parallel axis of rotation within the frame 6, and for scraping from the molding roll 4. Dough cutter3. A plurality of molds (in the form of cavities for receiving the dough) are formed in the surface of the molding roll 4 . The knife 3 extends between its ends 31, 32 along the molding roll 4 ( figure 2 ), and scrape excess dough from the surface of die roll 4. figure 1 The scraping position of the knife 3 extending into the gap between the die roll 4 and the feed roll 5 is shown. In the rest position, the knife 3 will be away from the molding roll 4 . The movement between the scraping position and the non-working position is controlled by figure 1 Indicated by double arrows in .

[0043] A hopper 27 is provided for supplying dough to the rollers 4 , 5 and a (rubber) belt 28 is provided for receiving shaped dough pieces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com