Ice core preparation device and method

A technology for preparing devices and ice cores, which is applied in ice making, ice making, lighting and heating equipment, etc., which can solve the problems of low ice making efficiency and difficulty in meeting the needs of rockets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

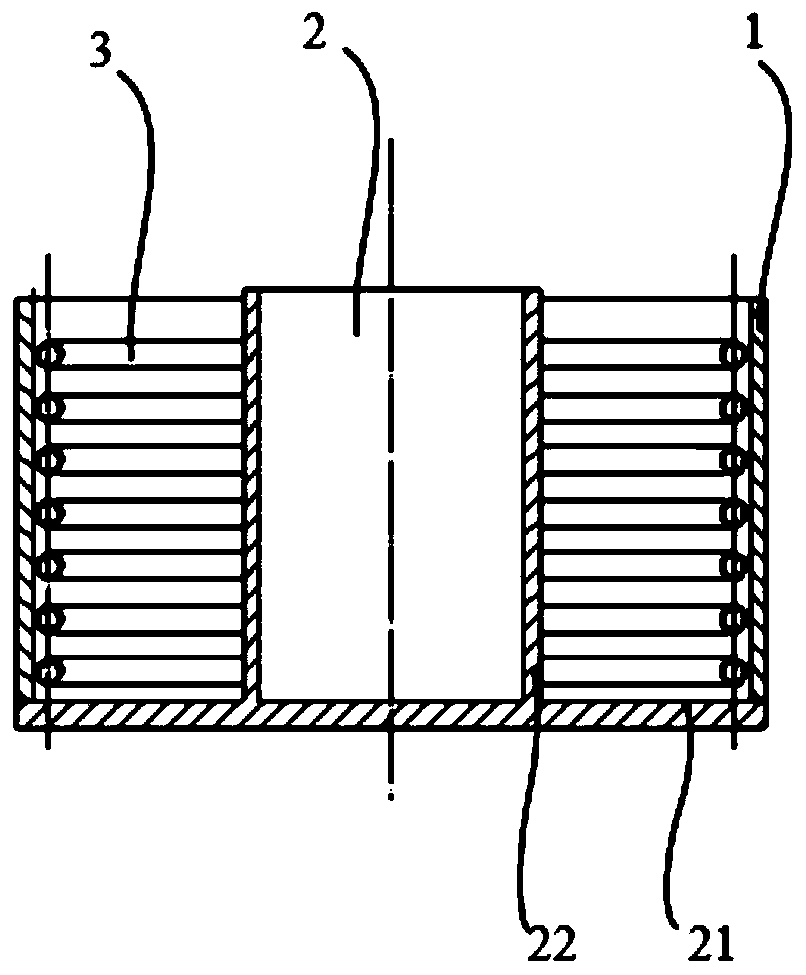

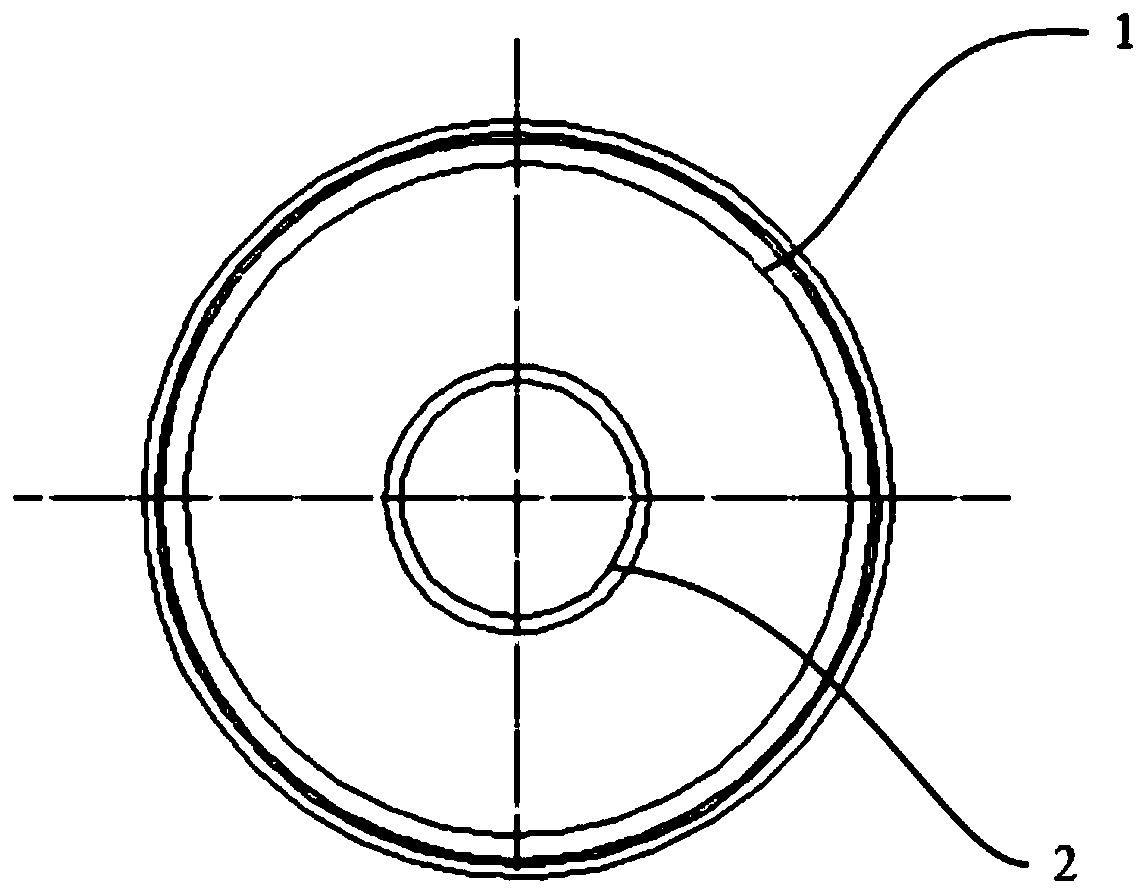

[0046] refer to figure 1 , showing the front view of an ice core preparation device provided in Embodiment 1 of the present invention, refer to figure 2 ,show figure 1 As shown in the top view of the ice core preparation device, the embodiment of the present invention is mainly described by taking the production of ice cores for solid rocket motor gas jet plume treatment systems as an example, and other types of ice core production can be referred to for implementation.

[0047] The ice core preparation device provided by the embodiments of the present invention may specifically include:

[0048] The first ice-making module 1, the first ice-making module 1 is a shell, for the solid rocket motor, the first ice-making module 1 is the shell of the importing module, which is used to make the ice core of the importing module.

[0049] The second ice-making module 2 is arranged inside the first ice-making module 1, and is used to form an inner mold when preparing ice cores. For s...

Embodiment 2

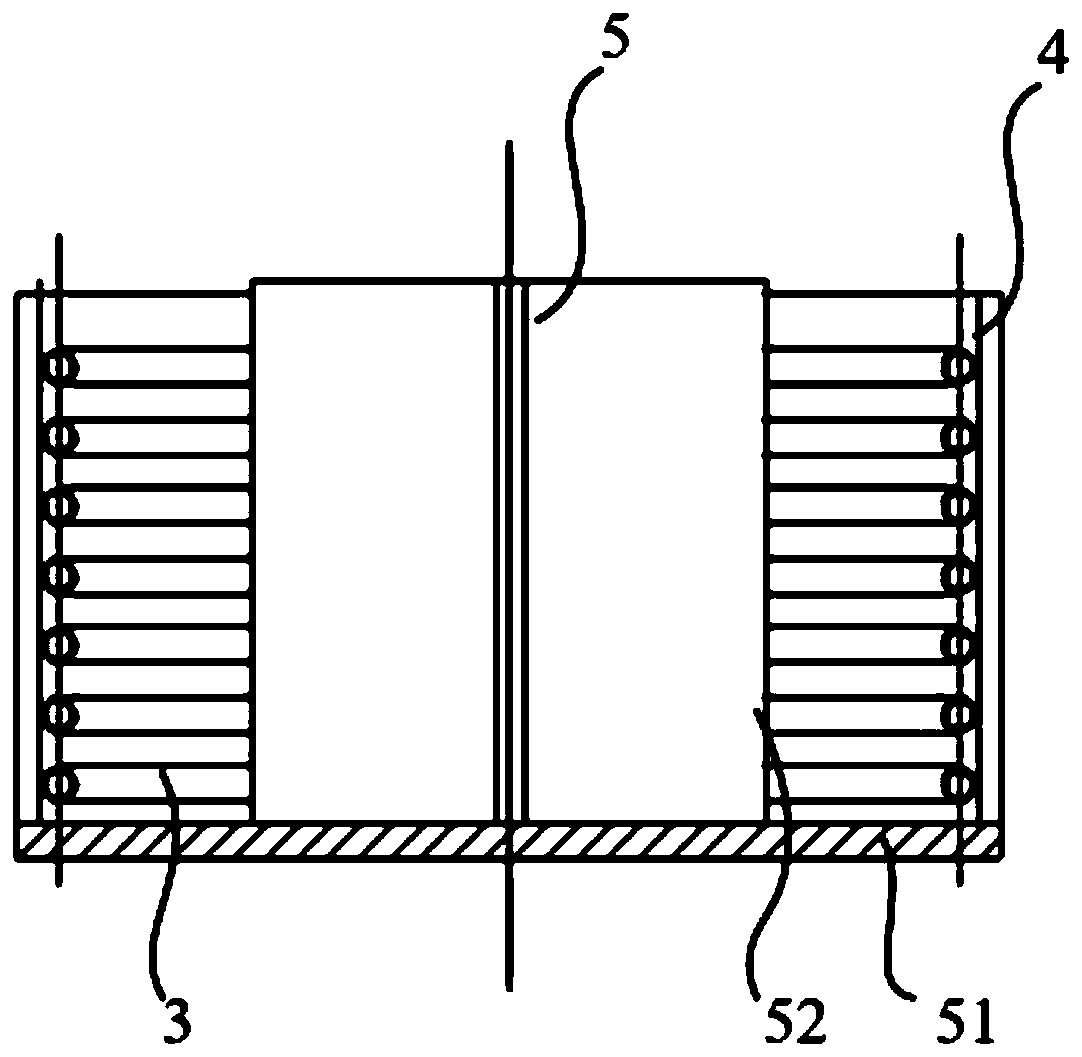

[0067] refer to image 3 , which shows the front view of an ice core preparation device provided in Embodiment 2 of the present invention, refer to Figure 4 ,show image 3 Top view of the ice core preparation apparatus shown. The difference from the first embodiment is that the ice core preparation device provided in the second embodiment is used to prepare the processing module ice core for the gas jet plume treatment system of the solid rocket motor.

[0068] Specifically, the first ice-making module 4 is a processing module shell, which is used to make ice cores of the processing module.

[0069] The second ice-making module 5 is arranged inside the first ice-making module 4, and is used to form an inner mold when preparing ice cores. For solid rocket motors, the second ice-making module 5 includes: a bottom plate 51 and a base plate 51 Connected bracket 52; wherein,

[0070] The bottom plate 52 is used for sealing connection with the first ice making module 4;

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com