Novel double-cavity paint spraying aerosol can structure

An aerosol can, a new type of technology, applied in the field of painting, can solve the problems of lack of automatic assembly line rapid production equipment, unstable product quality, slow production process speed, etc., and achieve the effect of simple structure, low production cost and convenient opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

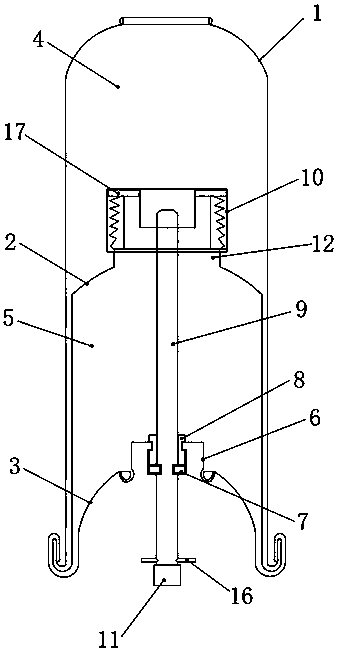

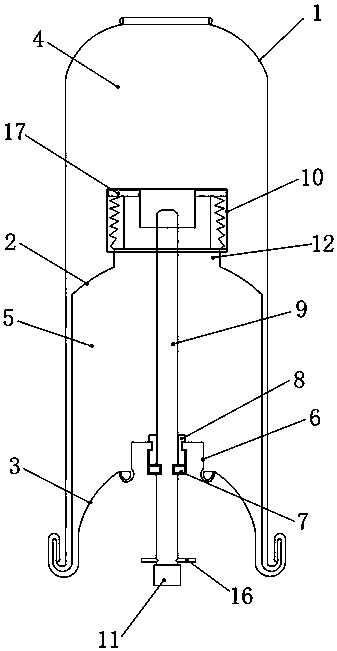

[0025] Such as figure 1 As shown, the new dual-cavity paint spray aerosol can structure provided by this embodiment includes an outer can body 1, an inner can body 2 is sleeved on the inside of the outer can body 1, and a corresponding sealing outer body is provided at the bottom of the inner can body 2 The bottom cover 3 of the tank body 1 and the inner tank body 2, the bottom cover 3 protrudes toward the inner side of the inner tank body 2, a paint containing cavity 4 is provided between the outer tank body 1 and the inner tank body 2, and the inner tank body 2 and the bottom There is a curing agent accommodating cavity 5 between the covers 3, a mixing assembly seat 6 is arranged in the center of the bottom cover 3, a sealing ring 7 is arranged on the mixing assembly seat 6, and a valve chamber is arranged on the inner side of the mixing assembly seat 6 corresponding to the sealing ring 7 8. The central corresponding seal ring 7 and the valve chamber 8 of the mixing assembly s...

Embodiment 2

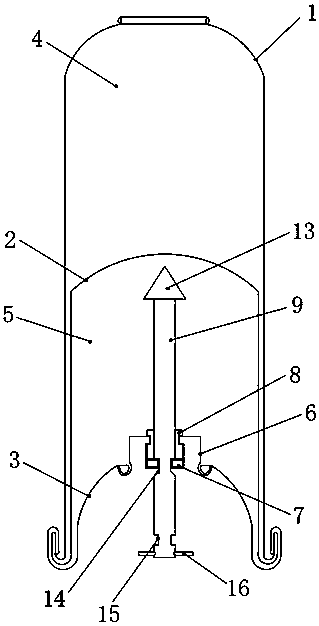

[0031] Such as figure 2 Shown as figure 1 As shown, the new dual-cavity paint spray aerosol can structure provided by this embodiment includes an outer can body 1, an inner can body 2 is sleeved on the inside of the outer can body 1, and a corresponding sealing outer body is provided at the bottom of the inner can body 2 The bottom cover 3 of the tank body 1 and the inner tank body 2, the bottom cover 3 protrudes toward the inner side of the inner tank body 2, a paint containing cavity 4 is provided between the outer tank body 1 and the inner tank body 2, and the inner tank body 2 and the bottom There is a curing agent accommodating cavity 5 between the covers 3, a mixing assembly seat 6 is arranged in the center of the bottom cover 3, a sealing ring 7 is arranged on the mixing assembly seat 6, and a valve chamber is arranged on the inner side of the mixing assembly seat 6 corresponding to the sealing ring 7 8. The central corresponding seal ring 7 and the valve chamber 8 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com