Substrate processing apparatus including an ascending and descending guide part

A technology for a substrate processing device and a guiding part, which is applied in the fields of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as increasing the size of the chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Since the chuck 200 includes various structures such as a structure for fixing the substrate 10 and controlling the temperature, there is a problem that the size of the chamber 100 is increased in order to secure a space for the chuck 200 to rise inside the chamber 100; The weight of 200 requires more power for lifting; various structures included in the chuck 200 also need to be raised and lowered together with the chuck 200 .

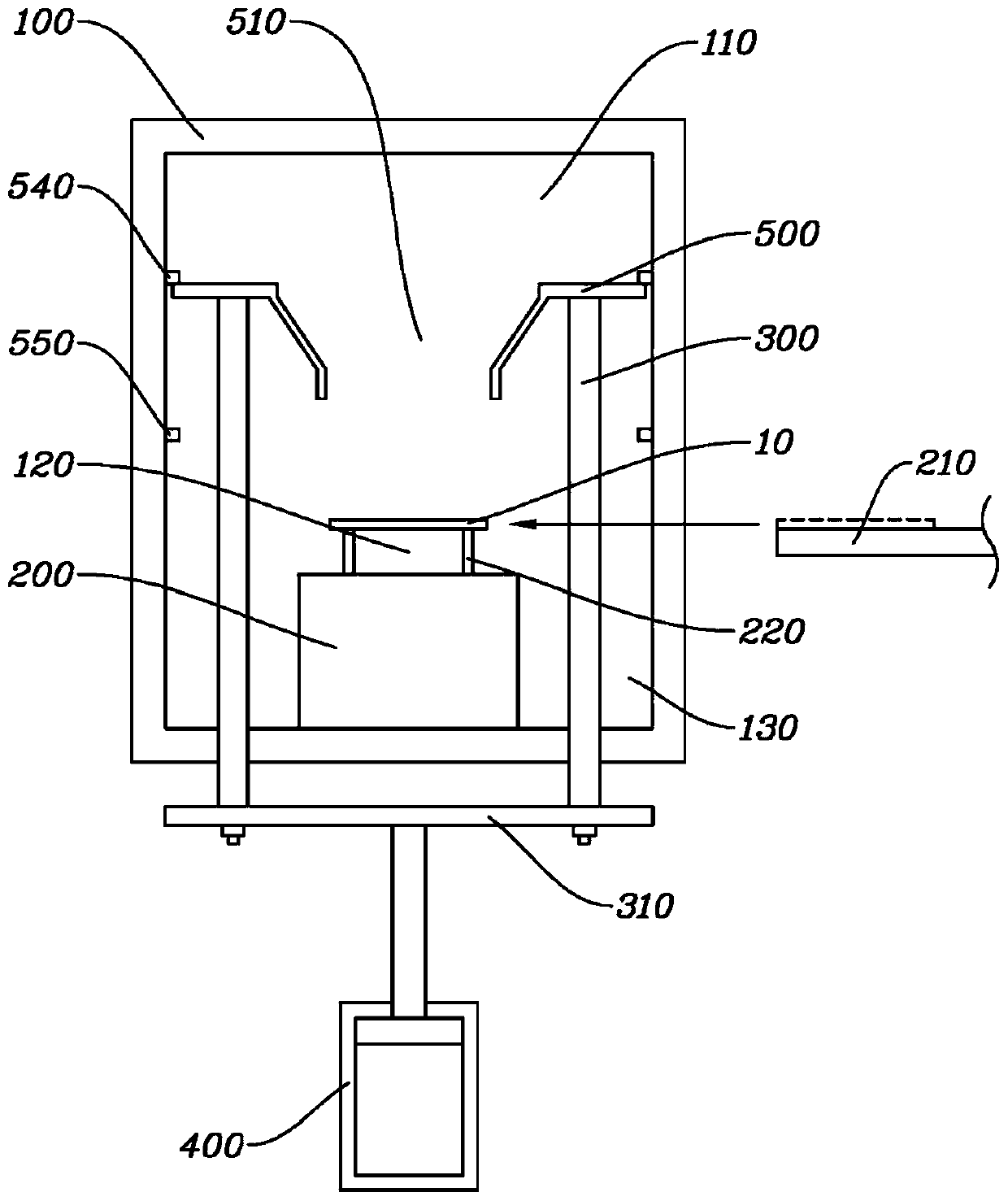

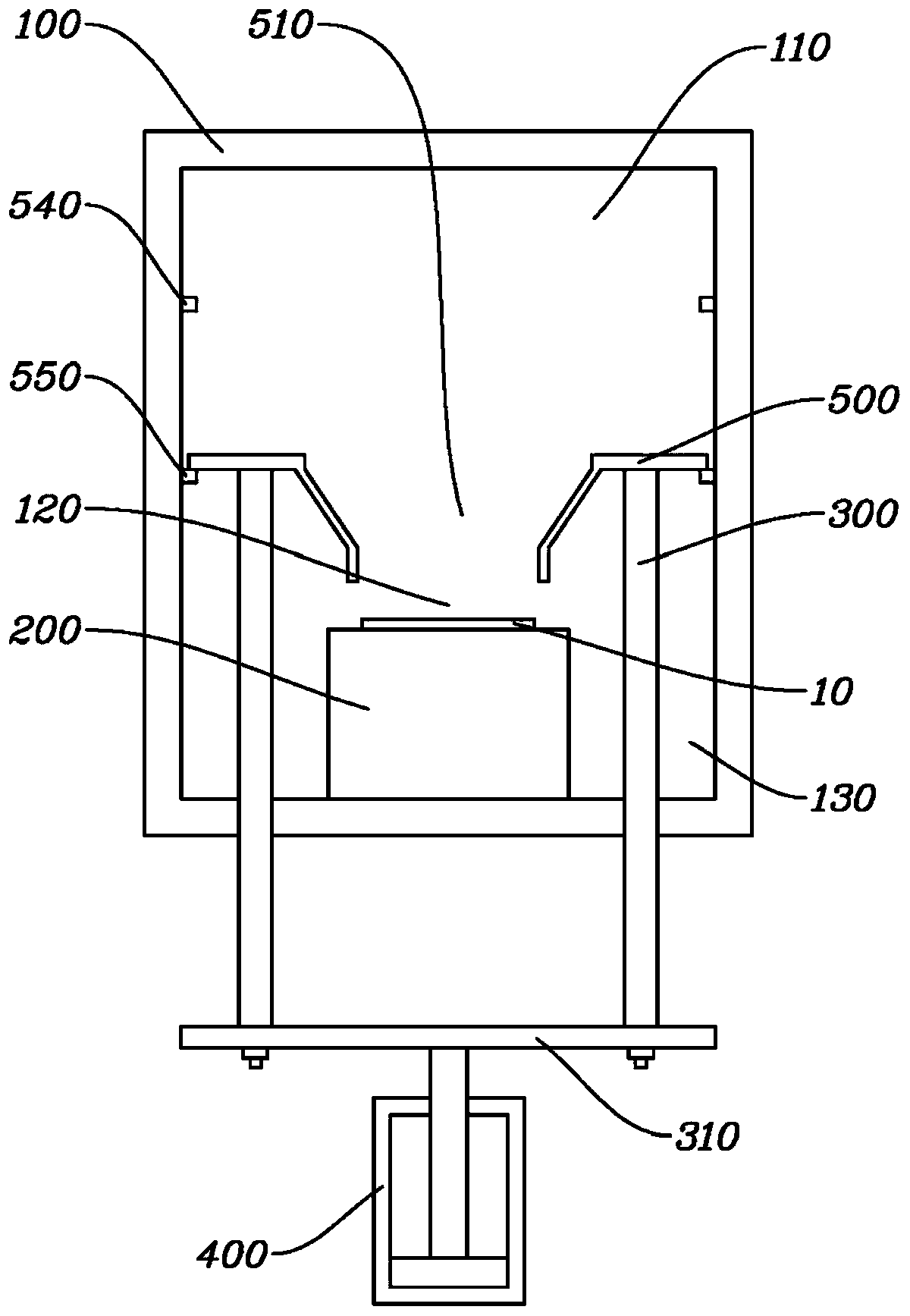

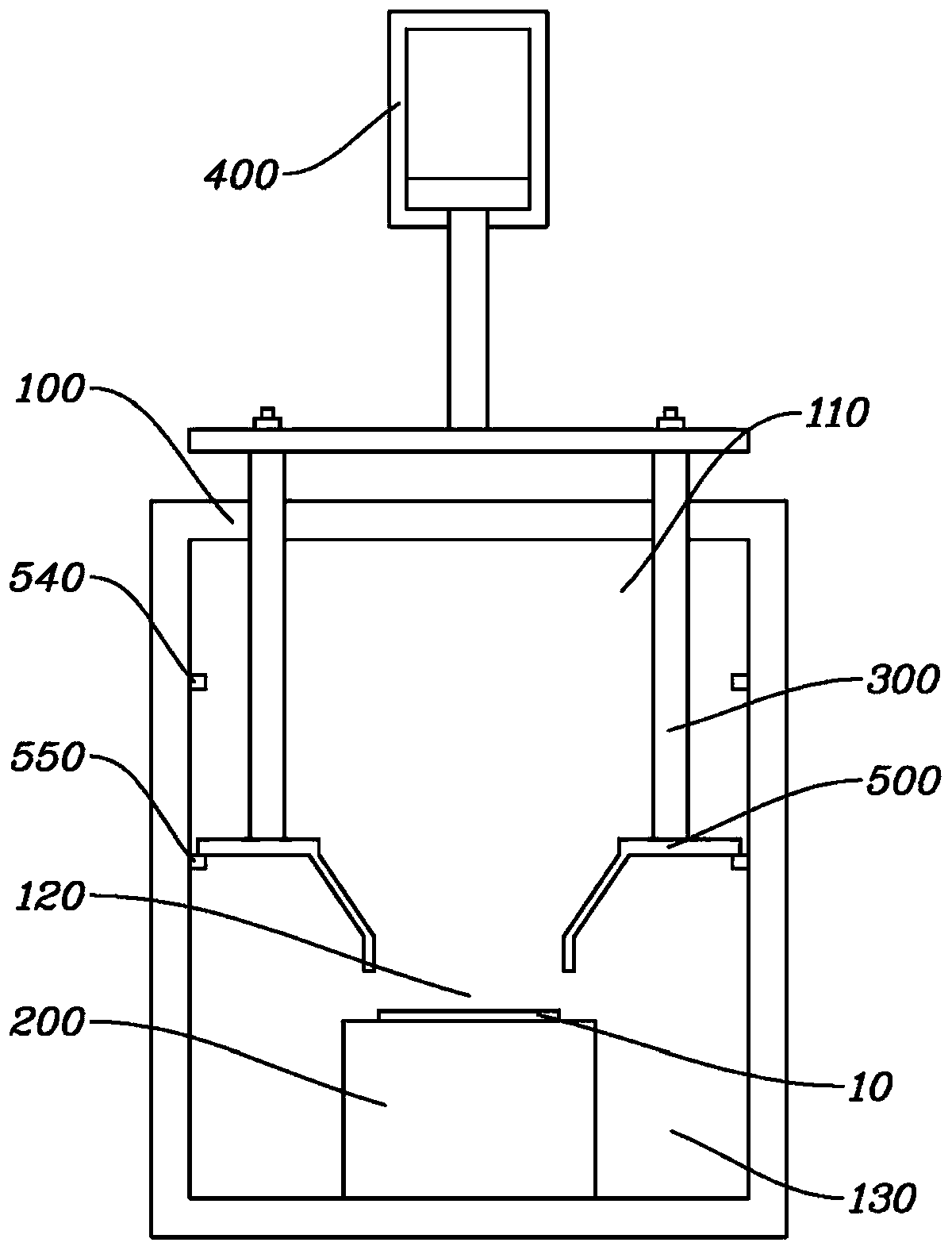

[0045] To solve this problem, such as figure 1 and figure 2 As shown in the figure, the substrate processing apparatus including the lifting guiding part of the present invention includes a chamber 100 , a chuck 200 , a guiding part 500 , a linkage part 300 and a driving part 400 .

[0046] The chamber 100 includes a formation area 110 as a area for forming a processing substance, a processing area 120 as a region for processing the substrate 10 with the processing substance, and a discharge area 130 as a region connected to a pump to dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com