An aluminum electrolysis cell superheat degree state recognition method and system based on a 3D convolutional neural network

A convolutional neural network and state recognition technology, applied in the field of aluminum electrolysis, to achieve the effect of improving accuracy, improving production efficiency, and improving comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

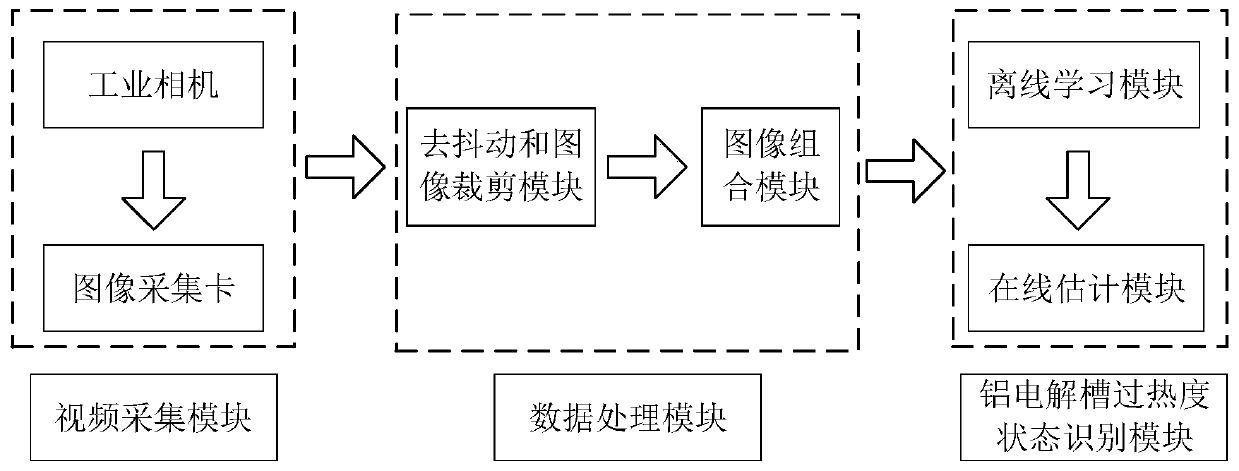

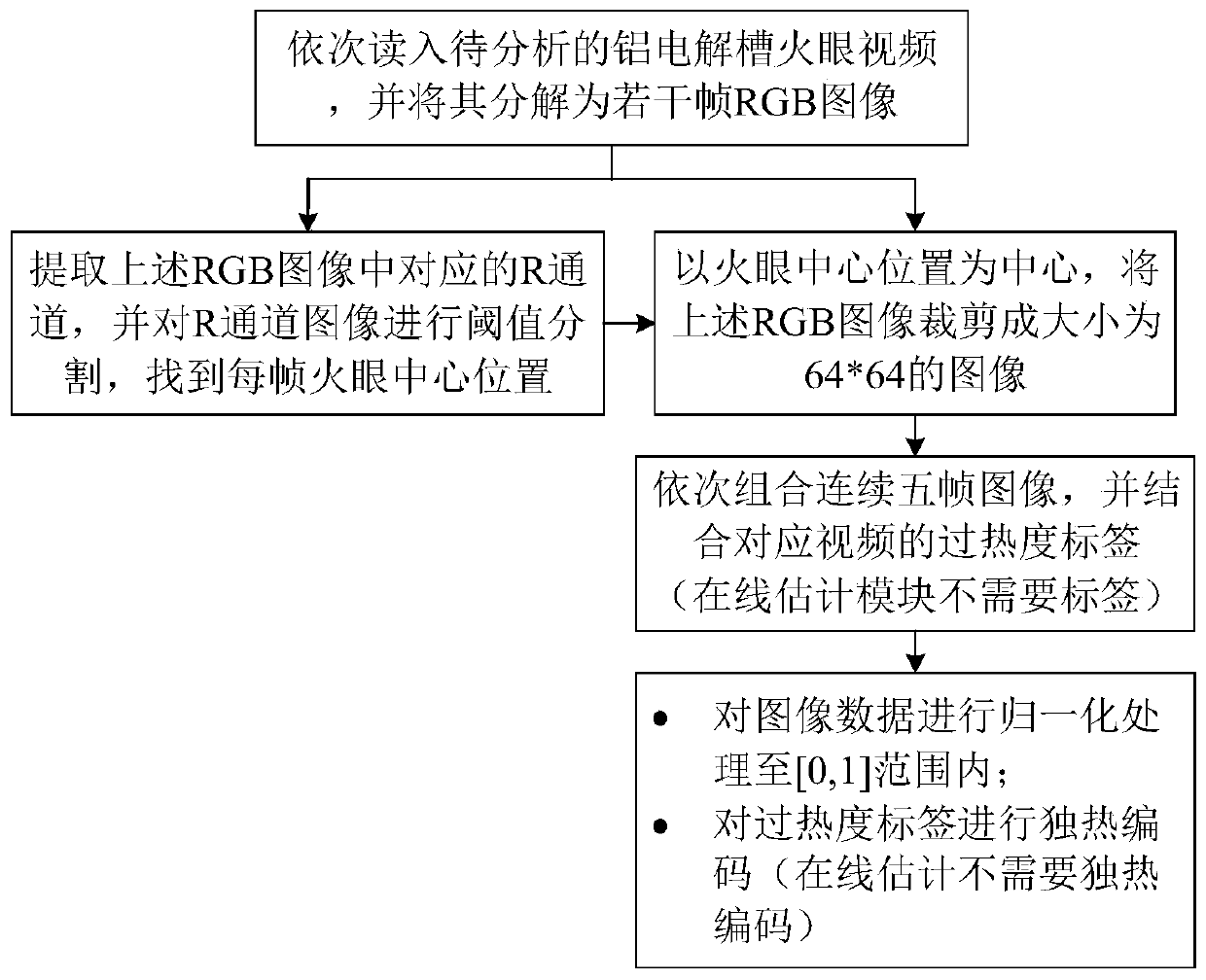

[0031] The specific implementation of the present invention will be described below in conjunction with the accompanying drawings, and the superheat state of the aluminum electrolytic cell is divided into three categories: large, normal, and small according to the actual operating conditions.

[0032] 1. Video capture module

[0033] From an aluminum electrolysis factory, a hand-held industrial camera was used to shoot 22 videos of different superheating states. The size of each frame of the video is 1920*1080, and the average duration of each group of videos is 80s, and then the collected videos are saved to the image acquisition stuck.

[0034] 2. Data processing module

[0035] Read the collected video data from the image acquisition card, decompose the read video data into multiple frames of RGB images, select the red channel in each frame of RGB images, and perform threshold segmentation on the red channel. The threshold value is 230, and after segmentation The binarize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com