Press-fit device for production of rigid-flex combining boards

A technology of rigid-flex board and lamination device, which is applied in multilayer circuit manufacturing, electrical components, printed circuit manufacturing, etc. It can solve the problems of lamination board structure misalignment, affecting the quality of finished products, offset, etc., and achieves convenient positioning , prevent offset, and ensure the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

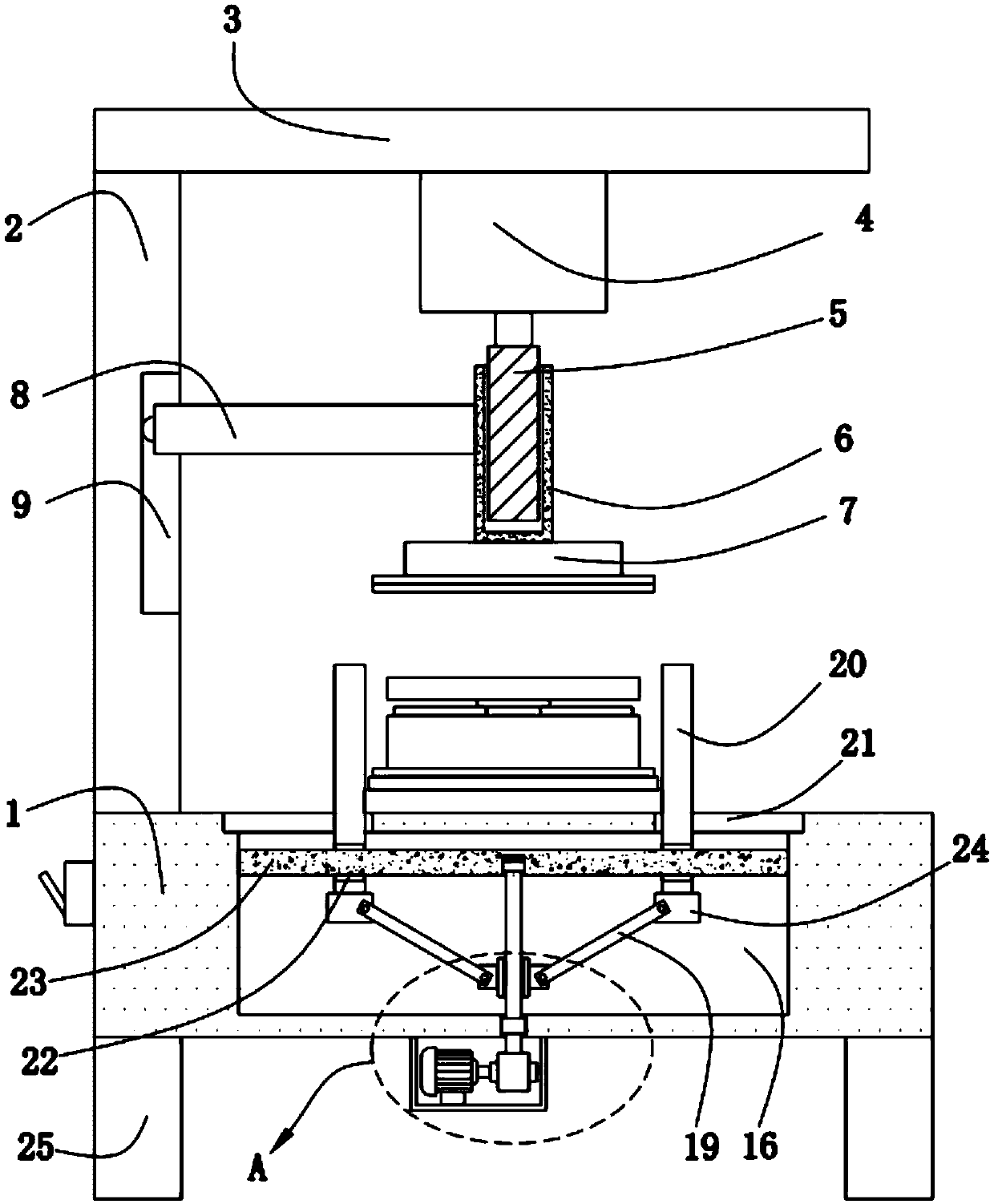

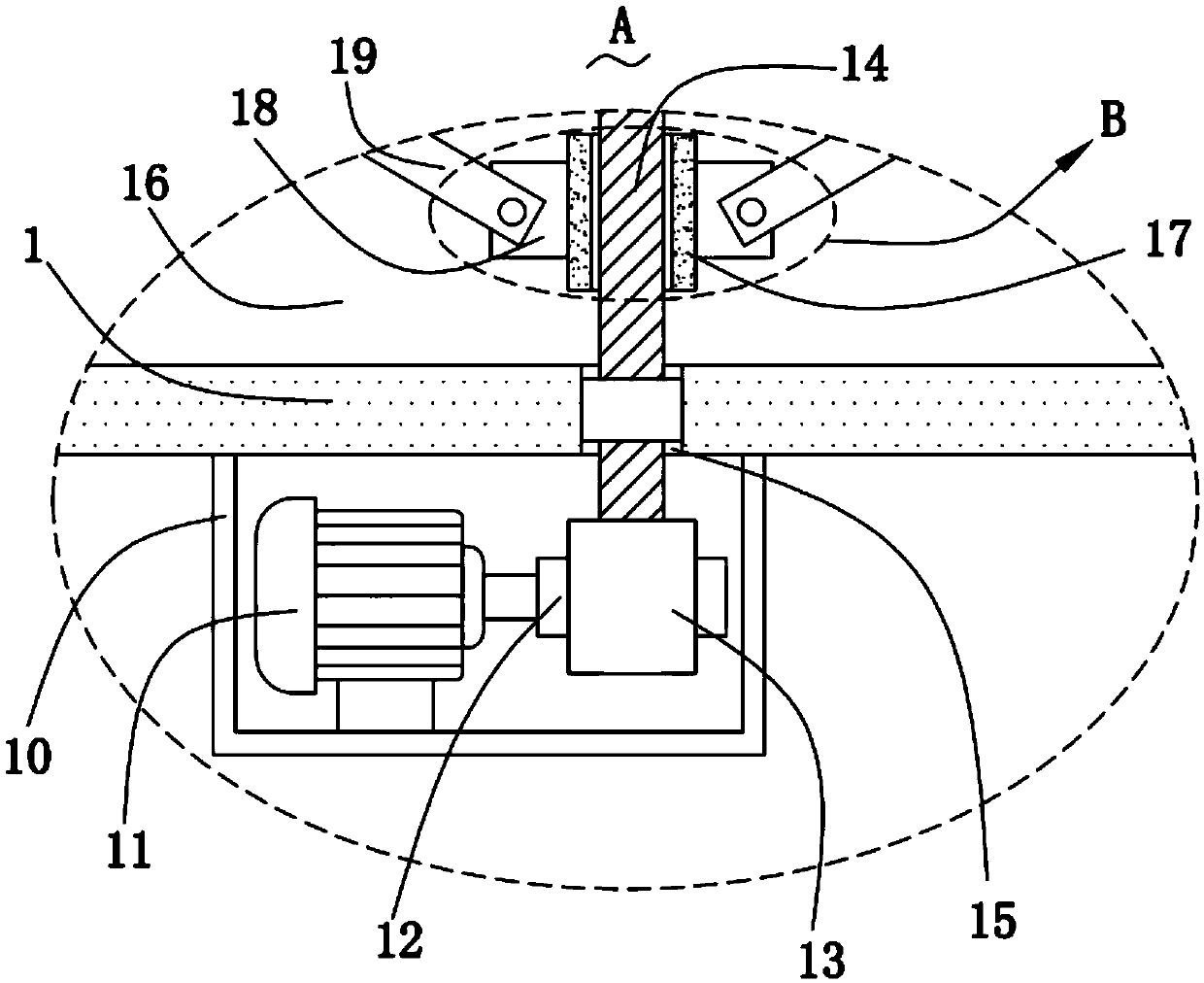

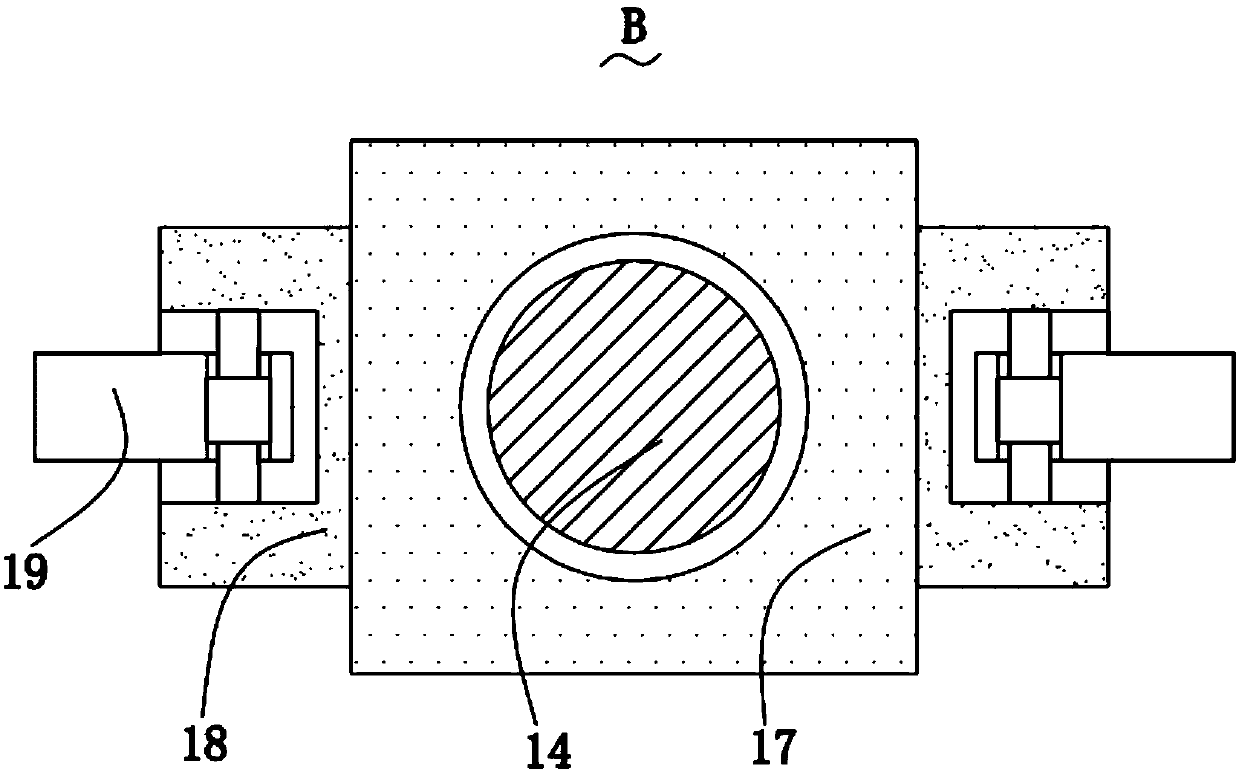

[0025] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 ,in, figure 1 A structural schematic diagram of a preferred embodiment of the pressing device for rigid-flex board production provided by the present invention; figure 2 for figure 1 The enlarged schematic diagram of part A shown; image 3 for figure 2 The top sectional view of part B shown; Figure 4 for figure 1 Schematic diagram of side view structure; Figure 5 for figure 1 Assembly drawing of turbine and worm shown. The pressing device for rigid-flexible board production includes: a platen 1; a support plate 2, the support plate 2 is fixedly installed on the top of the platen 1; a top plate 3, the top plate 3 is fixedly installed on the support plate 2 the top; the first motor 4, the first motor 4 is fixedly mounted on the bottom of the top plate 3; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com