Split type toilet bowl steady flow water effect detecting device

A detection device and toilet technology, which is applied in the testing of measuring devices, machine/structural components, and liquid tightness measurement using liquid/vacuum degree. , reduce time and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

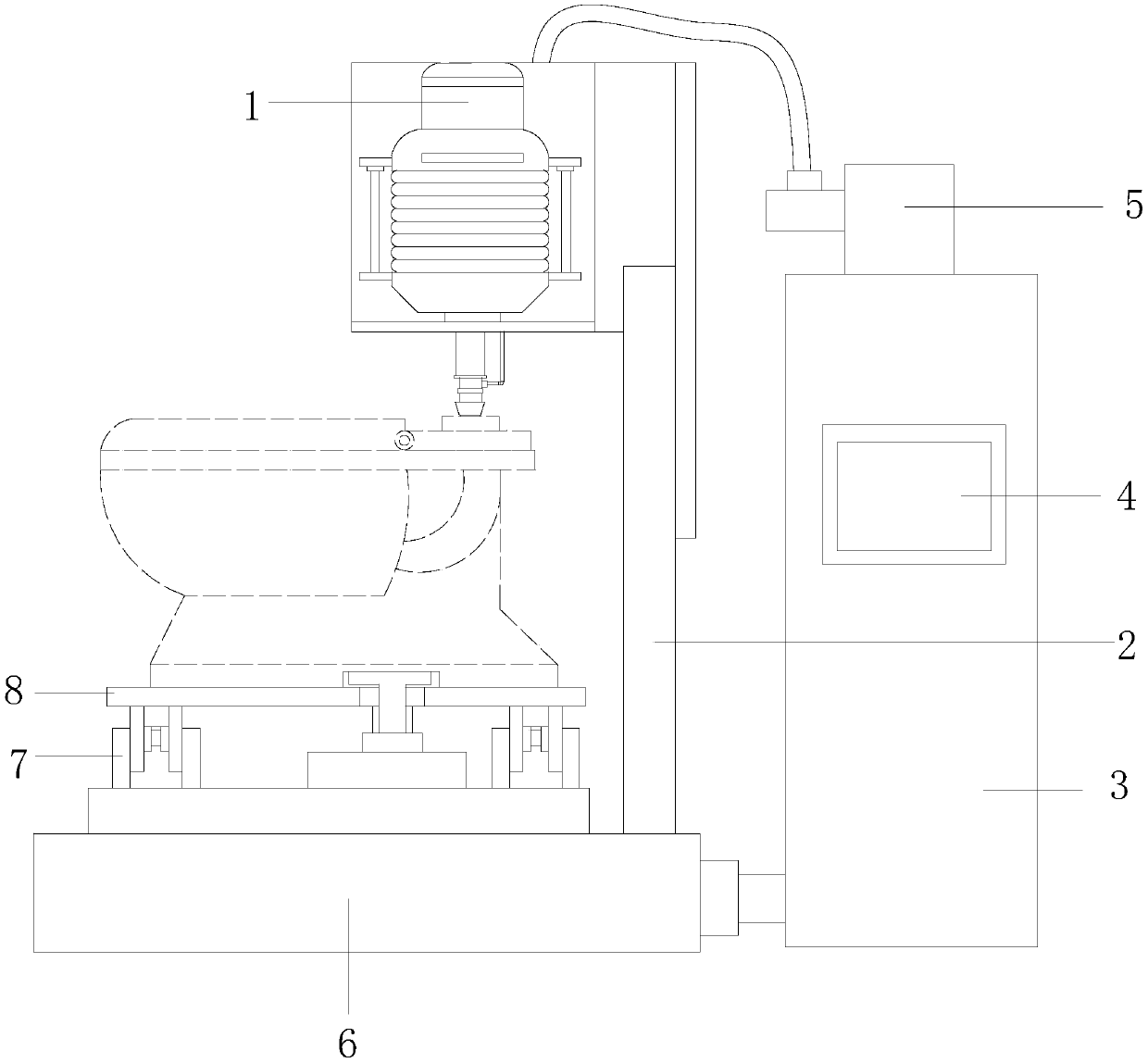

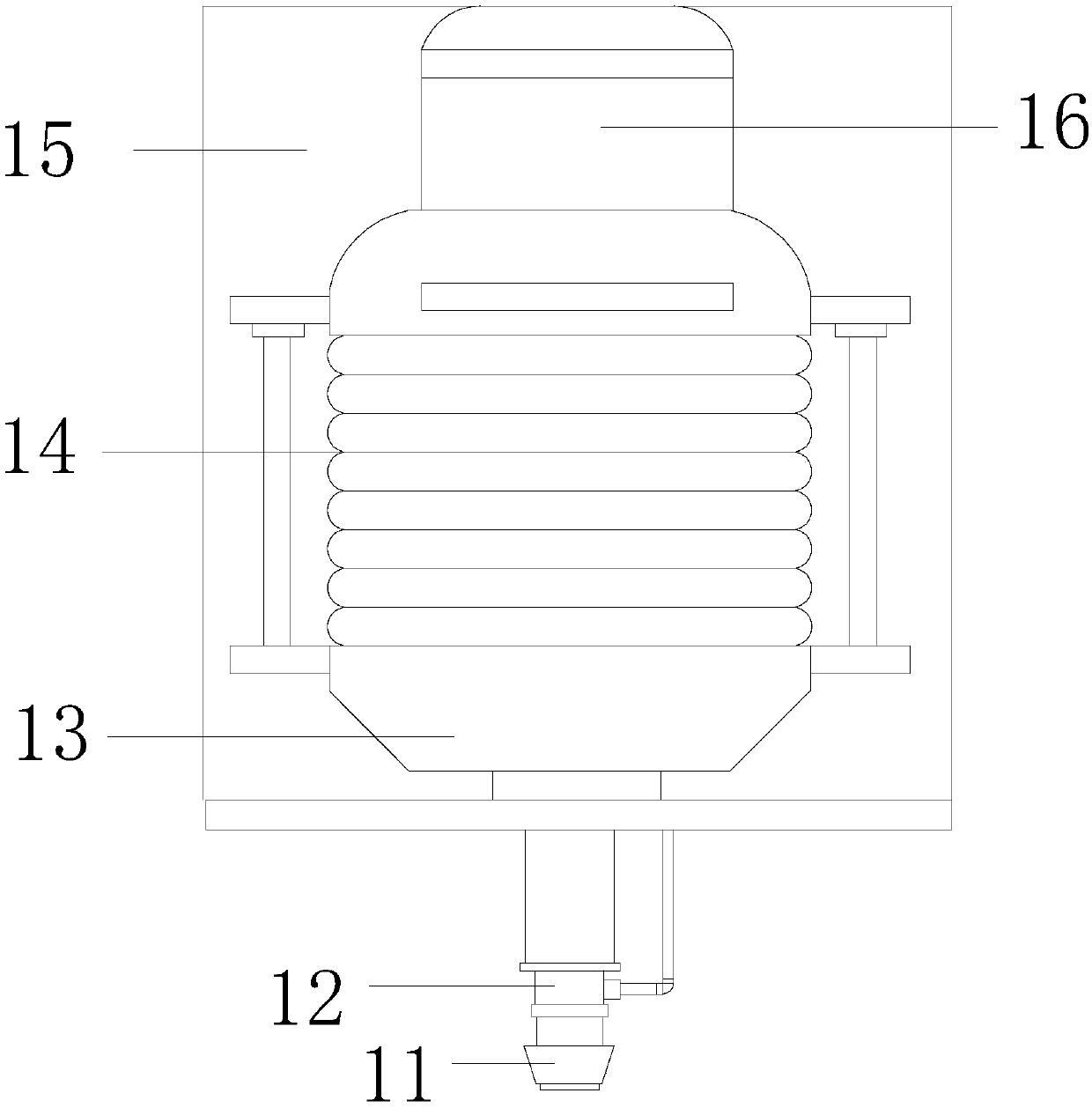

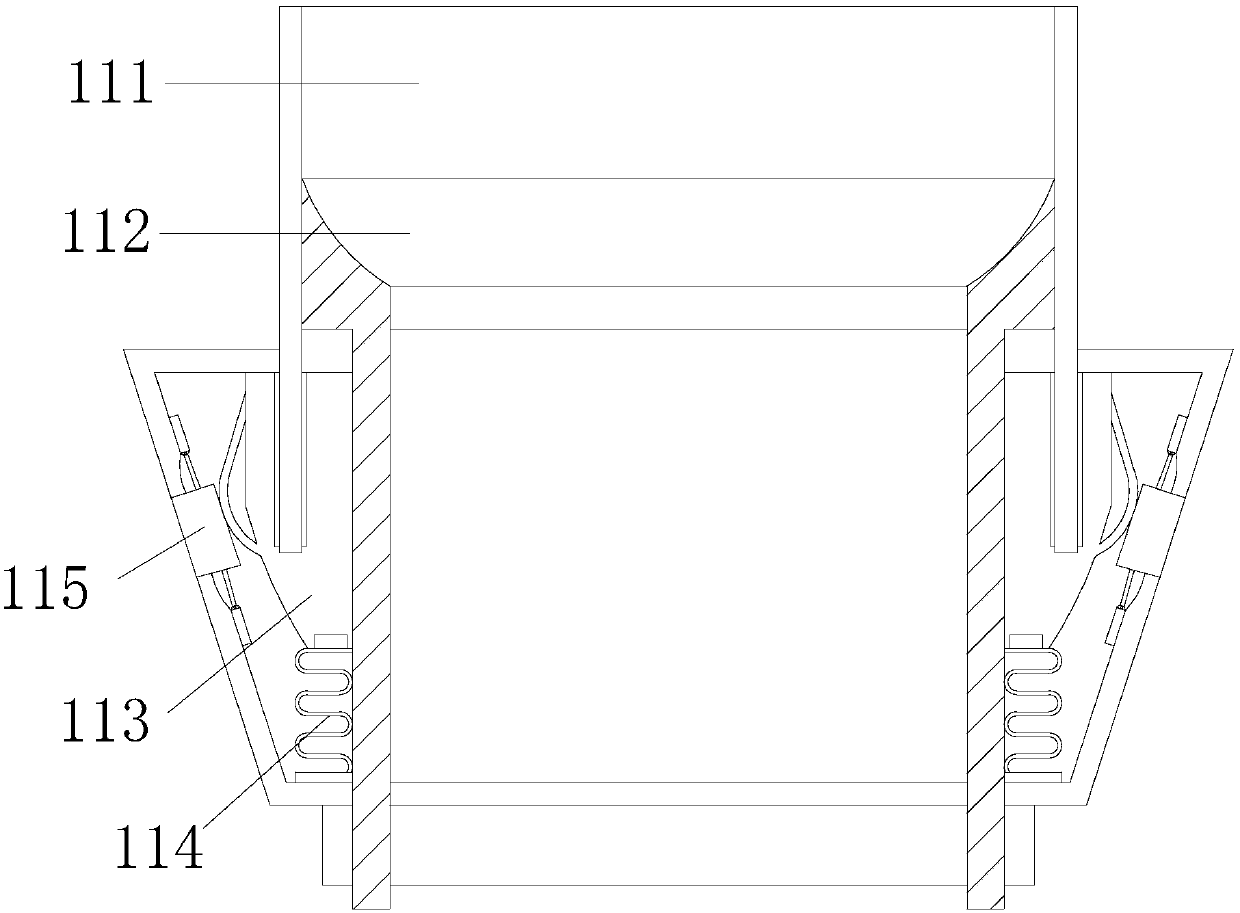

[0029] Such as Figure 1-Figure 10 As shown, the present invention provides a split type toilet steady flow water efficiency detection device, the structure of which includes: liquid equalization tank 1, lifting column 2, control cabinet 3, display screen 4, circulation pump body 5, recovery base 6, slide rails 7. Feeding base tank 8, the uniform liquid water tank 1 is vertically fixed on the center of the slider on the left side of the lifting column 2 through bolts, the lifting column 2 is installed on the left side of the control cabinet 3 and the two are parallel to each other, the The circulating pump body 5 is fixed on the top groove of the control cabinet 3 and is connected with the liquid equalizing water tank 1 on the left side through a pipeline. The display screen 4 is nested and fixed in the groove at the front end of the control cabinet 3. The feeding base tank 8 Horizontally placed on the top of the slide rail 7 and connected with the recovery base 6, the recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com