Photodiffusion polypropylene material and preparation method thereof

A technology of polypropylene material and light diffusion, which is applied in the field of modified materials with special properties of polymers. It can solve the problems that the haze and light transmittance cannot meet the requirements at the same time, the heat resistance performance cannot meet the requirements, and the weather resistance performance cannot meet the requirements. Achieve the effects of easy realization, low manufacturing cost and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

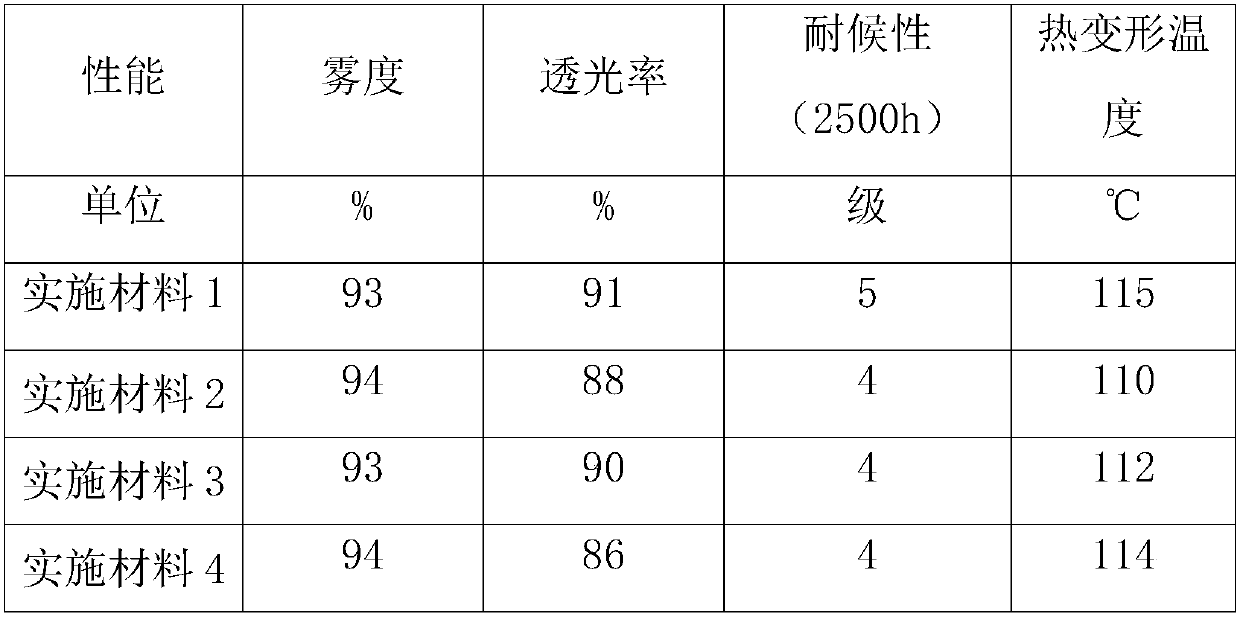

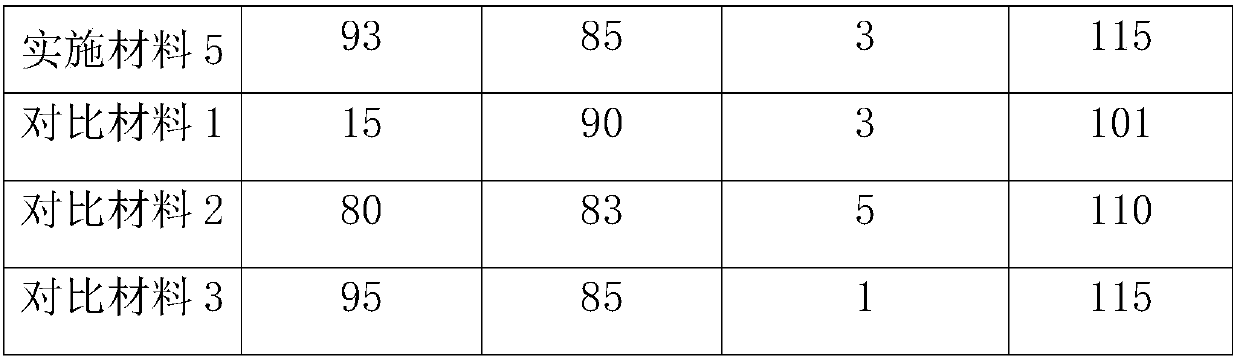

[0029] The present invention will be further described below in conjunction with embodiment.

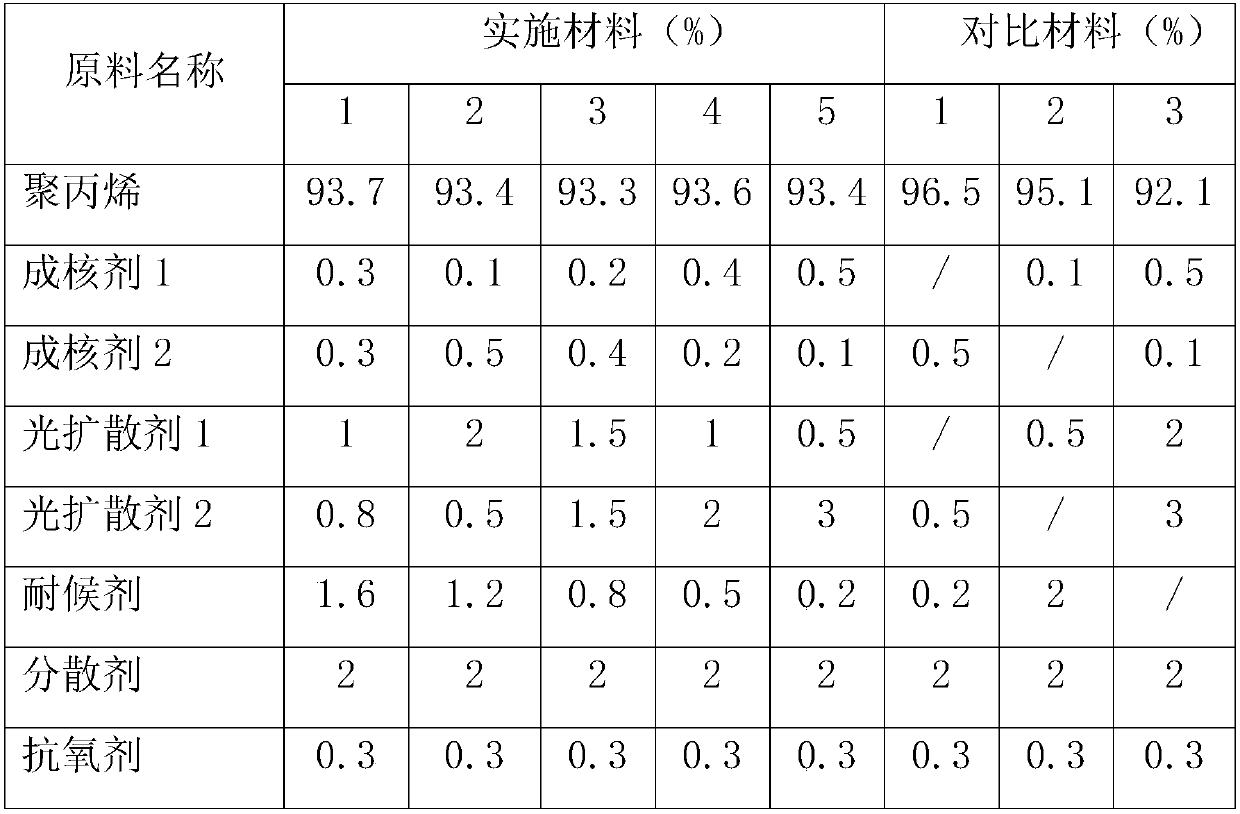

[0030] The light-diffusing polypropylene material includes the following components according to the weight percentage of raw materials: polypropylene: 85%-99%, nucleating agent: 0.1%-2%, light-diffusing agent: 0.1%-8%, weather resistance agent: 0.1% %-5%, dispersant: 0.1%-5%, antioxidant: 0.1%-1%.

[0031] Wherein, the nucleating agent includes nucleating agent 1 and nucleating agent 2, and is composed of the following components by weight percentage of raw materials: nucleating agent 1: 0.1%-1%, nucleating agent 2: 0.1%-1%.

[0032] The light-diffusing agent includes light-diffusing agent 1 and light-diffusing agent 2, and is composed of the following components by weight percentage of raw materials: light-diffusing agent 1: 0.1%-5%, light-diffusing agent 2: 0.1%-5%.

[0033] Further, it includes the following components in terms of raw material weight percentage: polypropylene: 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com