Strip-steel wave shape online detection system and method

A detection system and strip steel technology, which is applied in the field of strip steel cold rolling, can solve the problem that the actual wave shape of the strip steel cannot be obtained, and achieve the effect of offline query

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

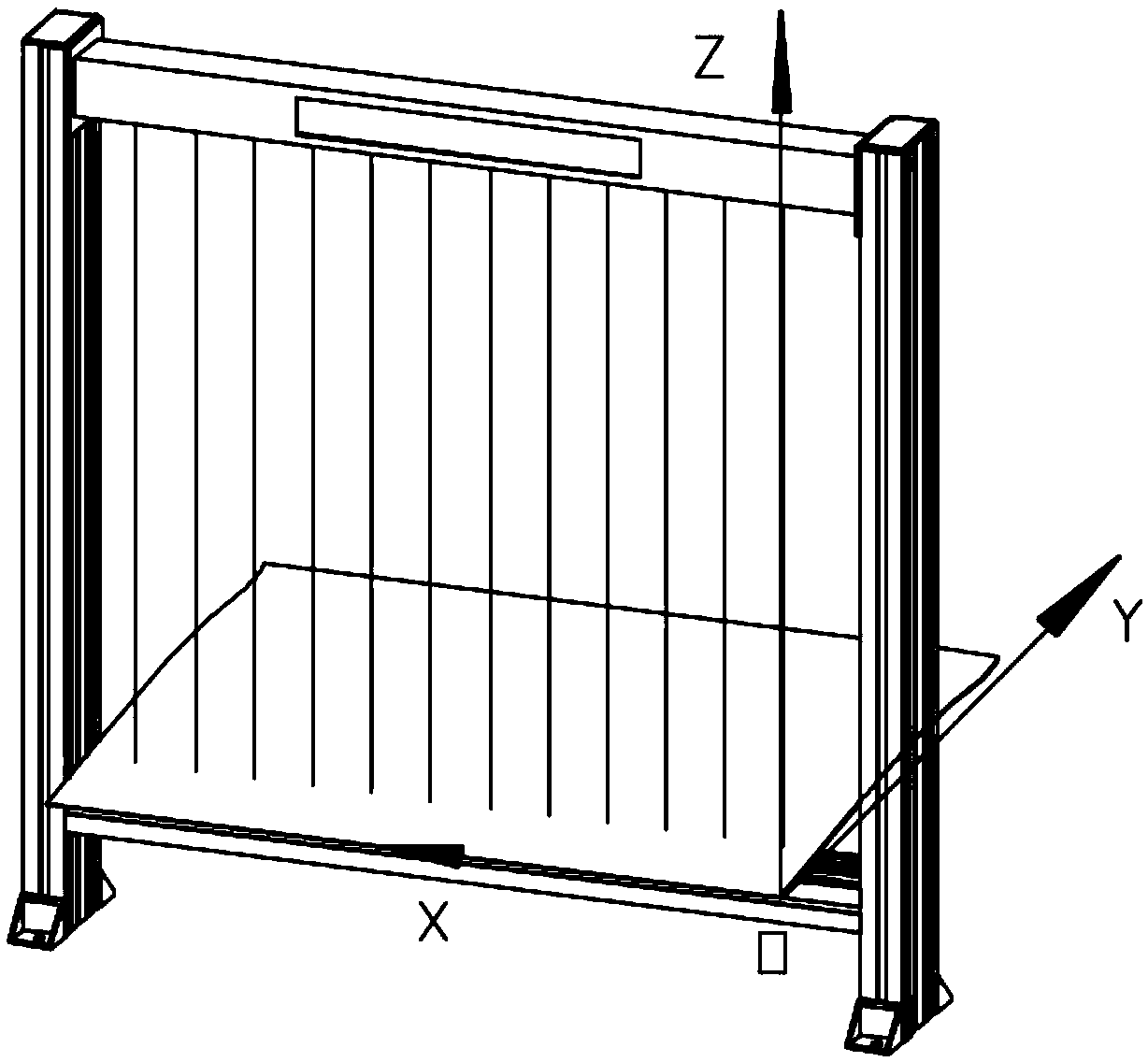

[0037] Embodiment 1: An online detection system for strip steel wave shape includes a detection unit, which is used for real-time detection of strip steel wave shape data.

[0038] see figure 1 , Figure 4 , Figure 5 and Image 6 , the detection unit has a frame 1, the frame 1 has a sensor installation crossbeam 11, and the bottom of the sensor installation crossbeam 11 is provided with several linear laser sensors 2 for measuring the wave shape of the strip steel, and the arrangement of the sensors is an array. The linear laser sensor 2 is connected with a multi-channel synchronous data acquisition controller 3 . The multi-channel synchronous data acquisition controller 3 is installed at the sensor installation beam 11 . The detection unit also has a strip position information sensor for measuring strip length information.

[0039] The installation position of the strip position sensor can be arranged according to the needs, for example, it is installed at the back idle...

Embodiment 2

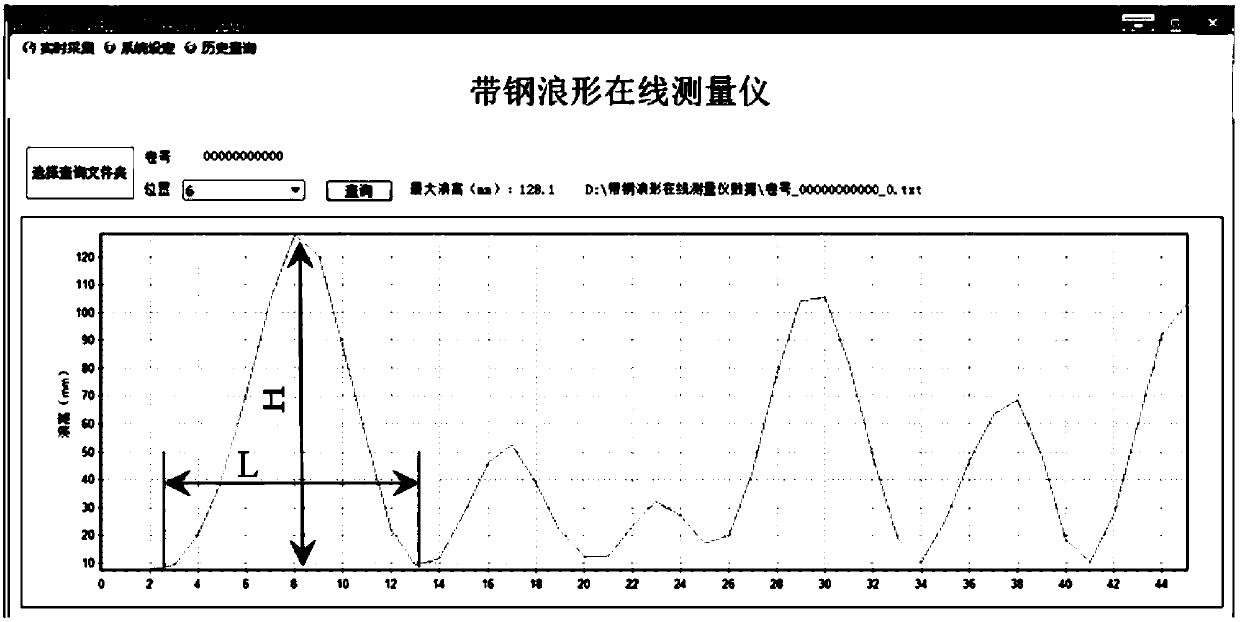

[0051] Embodiment 2: a kind of strip steel wave form on-line detection method, after the data processing unit receives the start detection signal that rolling mill upper computer sends, record the coil number of strip steel, receive the strip steel wave form detected in the strip steel detection unit simultaneously Data, the horizontal wave shape value of the strip detected by each sensor in the linear laser sensor in the strip detection unit is generated into a histogram and displayed on the screen, and the longitudinal detection data is generated into a curve and displayed on the screen. According to the collected strip Steel wave shape data, the maximum wave height value of the measured steel coil and the corresponding position are displayed on the screen for users to preliminarily judge the wave shape information. graphic reference figure 2 , in this figure, the top is a histogram, the abscissa in the figure represents the width of the strip, the ordinate represents the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com