Supported catalyst for catalytic oxidation desulfurization reaction and preparation method of supported catalyst

A supported catalyst, catalytic oxidation desulfurization technology, applied in the chemical field, can solve the problems of less recycling cycles, large removal rate drop, poor catalytic performance, etc., and achieve the effects of low preparation cost, reduced dosage, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of a supported catalyst for catalytic oxidation desulfurization reaction of the present invention comprises the following steps:

[0033] (1) Preparation of modified carrier:

[0034] Completely dissolve the metal salt in an excess acid solution, adjust the pH with lye, age, wash, dry, grind, and calcinate to obtain a modified carrier;

[0035] (2) Prepare supported catalyst:

[0036] After completely dissolving the modified carrier in water, a carrier solution is obtained;

[0037] The heteropolyacid is added into the carrier solution, impregnated and dried to obtain the supported catalyst.

[0038] Wherein, the metal salt includes at least one of ferric chloride, magnesium chloride hexahydrate, tin chloride pentahydrate, cobalt chloride hexahydrate, zirconium oxychloride octahydrate, zinc chloride, magnesium nitrate hexahydrate and iron nitrate nonahydrate. two kinds. Thus, the prepared modified carrier is at least two kinds of gas-phase magne...

Embodiment 1

[0048] The specific operation steps are as follows:

[0049] (1) Preparation of modified carrier:

[0050] 0.03mol of zirconium oxychloride octahydrate and 0.01mol of tin tetrachloride pentahydrate are respectively dissolved in the hydrochloric acid solution of 30ml, under stirring condition, tin chloride solution is dripped in the aqueous solution of zirconium chloride, makes it well mixed;

[0051] At room temperature, the pH of the solution was adjusted by ammonia solution, the solution appeared turbid, adjusted to pH 8, aged at 40°C for 2.5h, filtered, washed, and dried for 14h to obtain a solid, which was ground and placed in a muffle furnace Calcined for 3 hours, the temperature was kept at 500° C., and cooled to room temperature to obtain a modified carrier.

[0052] The modified carrier includes zirconia, stannous oxide and tin oxide.

[0053] (2) Prepare supported catalyst:

[0054] Dissolve 0.2g of phosphotungstic acid in 10ml of water, sonicate for 3min until th...

Embodiment 2

[0069] The specific operation steps are as follows:

[0070] (1) Preparation of modified carrier:

[0071] 0.3mol magnesium nitrate hexahydrate (MgNO 3 ) 2 ·6H 2 O and 0.1mol tin tetrachloride pentahydrate (SnCl 4 ·5H 2 0) be dissolved in the hydrochloric acid solution of 300ml respectively, under stirring condition, the magnesium nitrate aqueous solution is dripped in the tin chloride solution, obtains uniform solution;

[0072] At room temperature, adjust the pH to 9 with an ammonia solution, age at 50°C for 3h, filter, wash, and dry for 12h to obtain a solid, which is ground and calcined in a muffle furnace for 6h at a temperature of 500°C , cooled to room temperature and ground the sample to obtain the modified support.

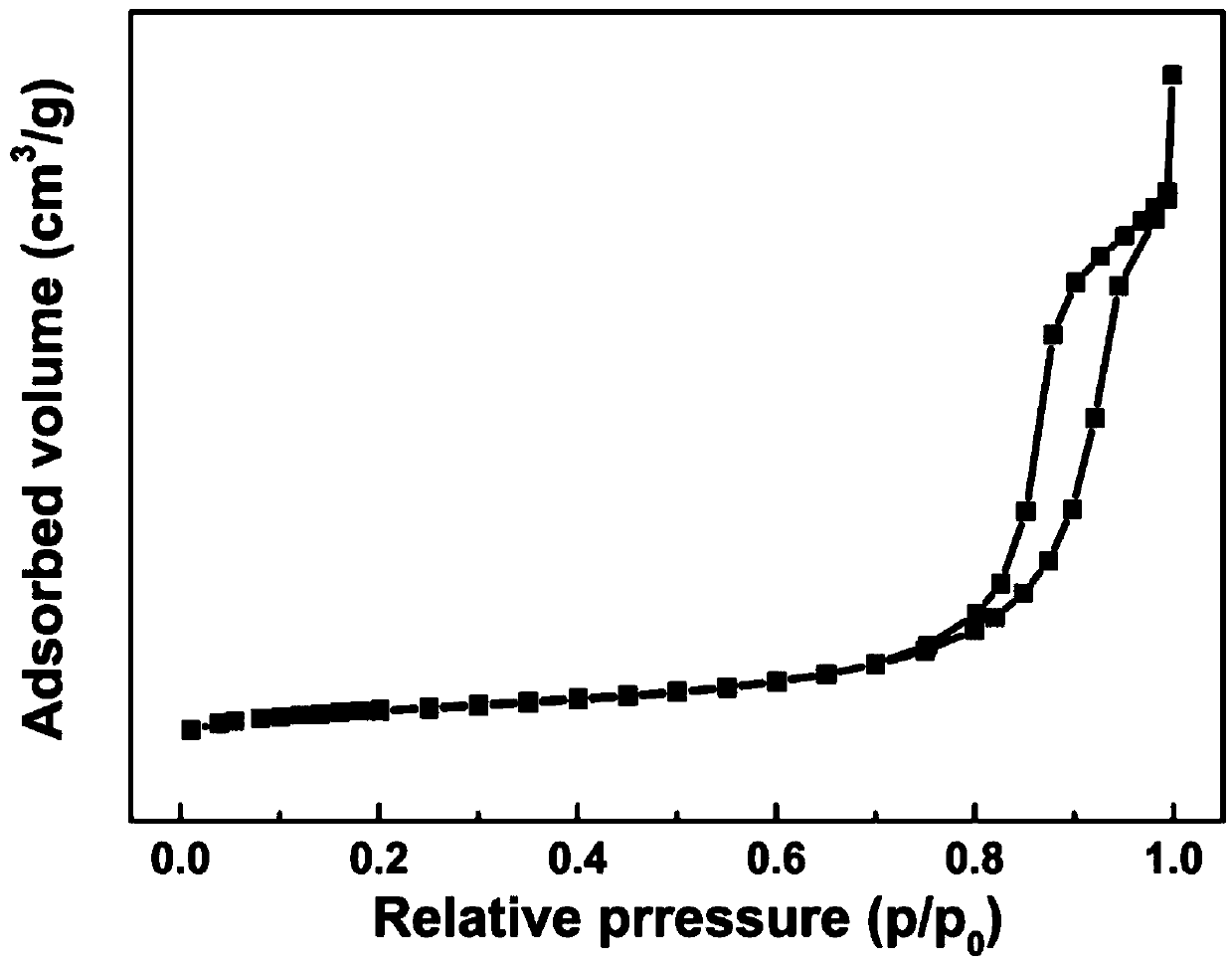

[0073] The modified carrier includes magnesium oxide, stannous oxide and tin oxide, and the specific surface area is 50m 2 / g.

[0074] (2) Prepare supported catalyst:

[0075] 1.6 g of the modified carrier was completely dissolved in 20 ml of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com