Bulk cement discharging equipment

A technology of bulk cement and equipment, which is applied in the field of bulk cement unloading equipment, can solve the problems of inconvenient transportation and use of the overall conveying device, and achieve good weighing effect, good effect of preventing material leakage, and small difference in cement weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

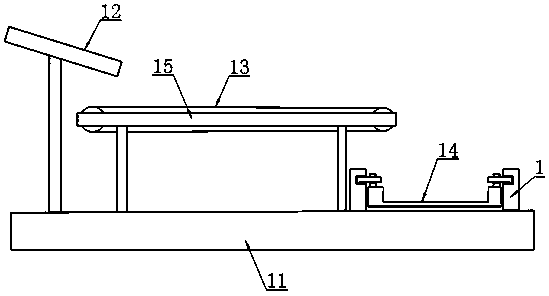

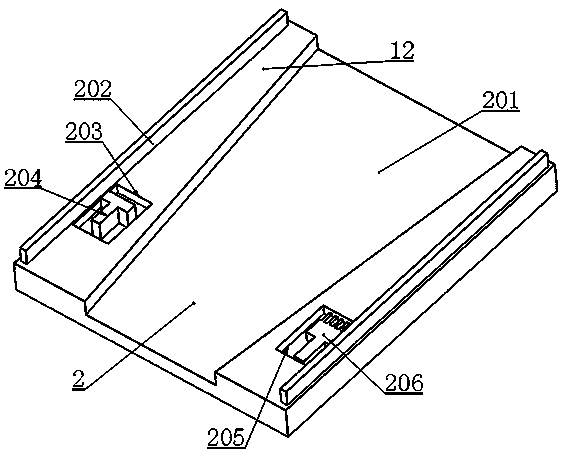

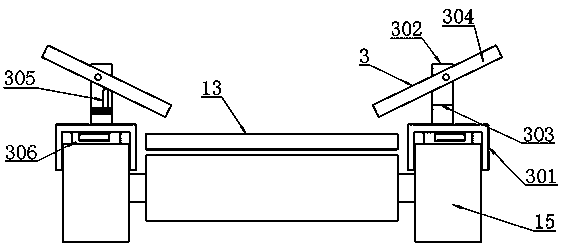

[0033] Example: as attached figure 1 , 2 , 3, 4, 5, 6 and attached Figure 7 As shown, a bulk cement unloading equipment includes a bottom plate 11, a material receiving sloping plate 12, a conveyor belt 13, and a material receiving frame 14 arranged on the bottom plate 11 in sequence, and also includes a material receiving sloping plate arranged on the material receiving sloping plate 12 on the upper surface and is used to gather the grooved unit 2 of the cement material, and is arranged on the conveying frame 15 and spreads the material receiving mode through the inclined plates on both sides to be used to gather the cement material to the conveyor belt 13 again. Board unit 3.

[0034] In this embodiment, the bulk cement falls on the sloping plate 12 from the discharge port, then slides down onto the conveyor belt 13, and then falls on the material receiving sloping plate 13 after being rotated and transported by the conveyor belt 13. On the frame 14, after the cement on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com