Pressure switch valve

A pressure switch and valve body technology, which is applied in the field of pressure switch valves, can solve the problems of over-reliance on circuit systems, induction repetition, and high production costs, and achieve the effects of avoiding induction repetition, saving costs, and getting rid of excessive dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

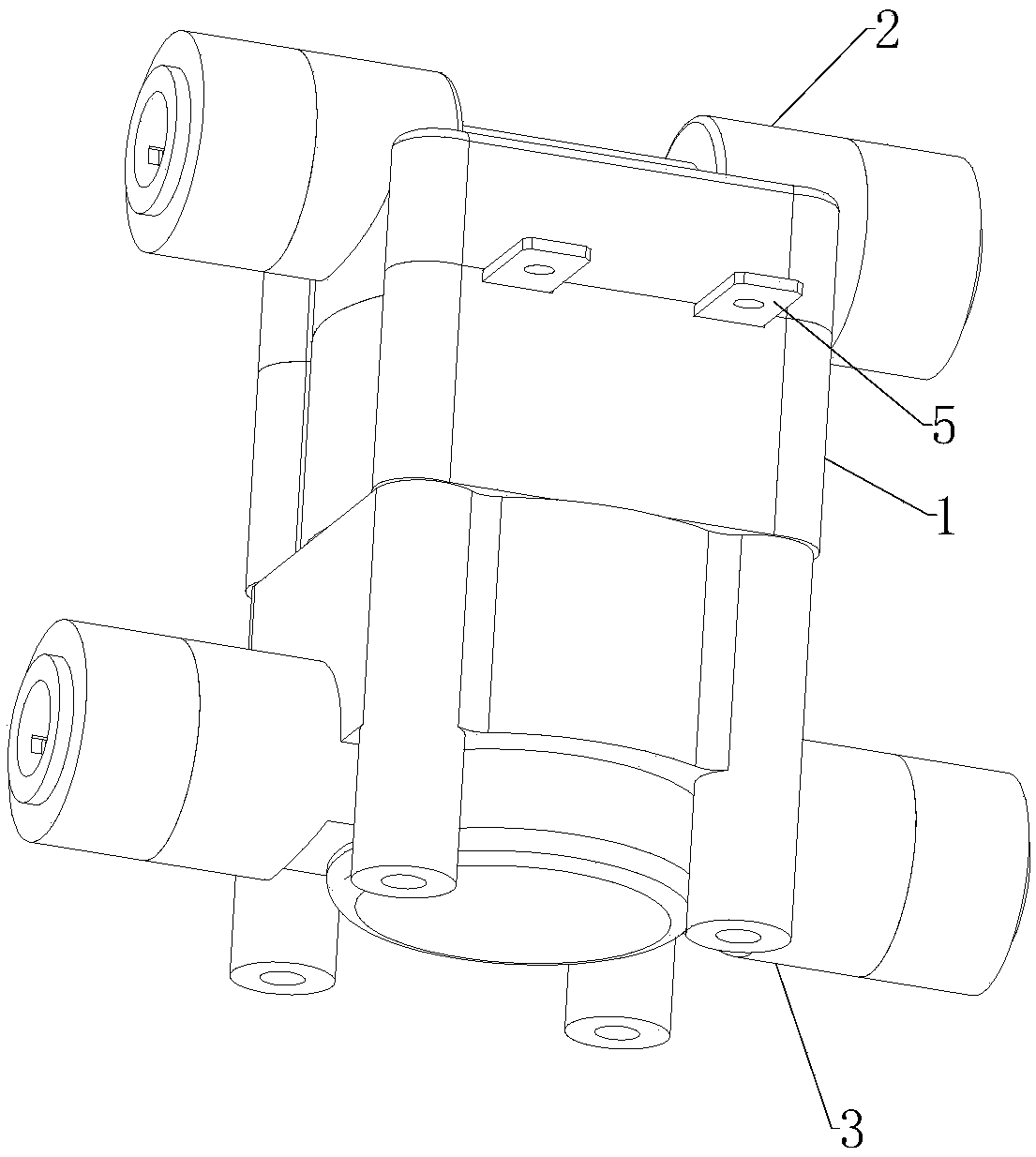

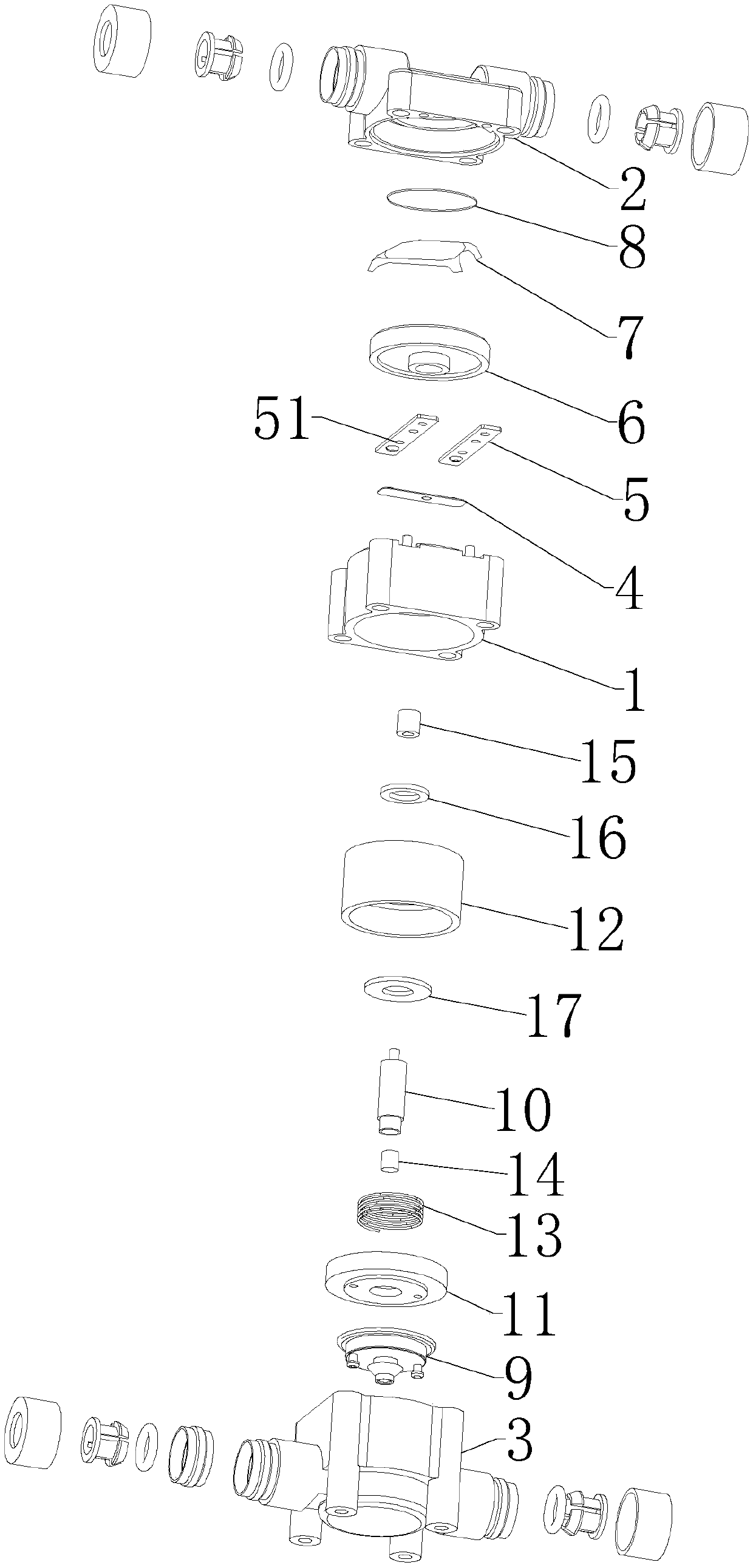

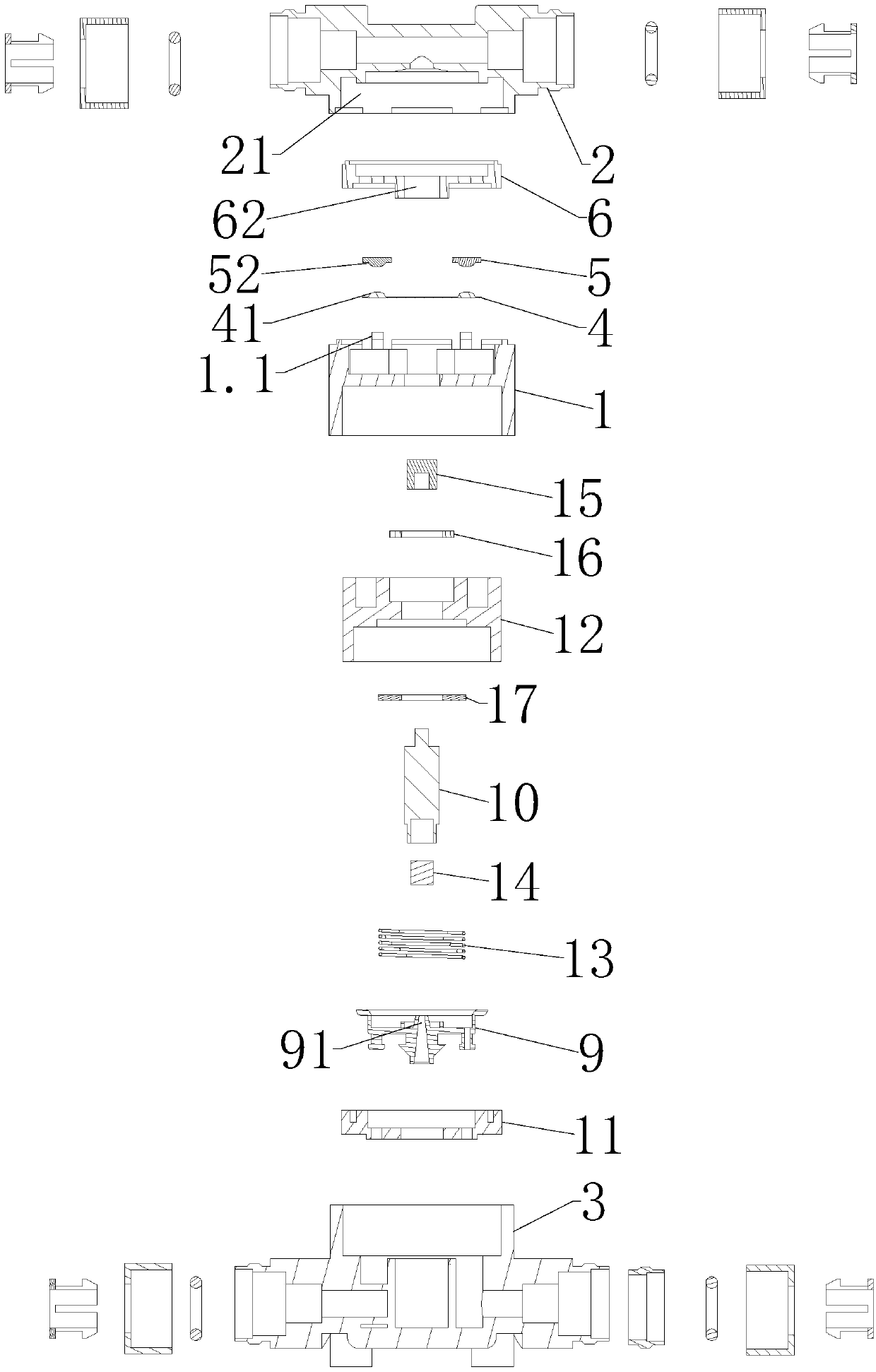

[0023] Embodiment one, such as figure 1 — Figure 4 As shown, the pressure switch valve includes a valve body 1, the upper and lower ends of the valve body 1 are respectively installed with a pure water pipeline 2 and a raw water pipeline 3, and a movable conductive piece 4 is placed in the valve body 1 and a connection with the movable conductive piece 4 is placed. The conductive piece 5 is fixed, a cover plate 6 is provided on the top of the valve body 1, and a shrapnel 7 is arranged inside the cover plate 6. The bottom end of the pure water pipeline 2 covers the cover plate 6, and a spring piece is arranged inside the bottom end of the pure water pipeline 2. The sealing diaphragm 8 on the 7, the top of the raw water pipeline 3 is provided with a valve core 9, the middle of the valve core 9 has a pilot hole 91, and a pilot hole 91 for opening or closing is provided between the valve core 9 and the valve body 1 and can An elastic return device that moves up and down, the ela...

Embodiment 2

[0034] Embodiment two: if Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that it removes the soft block 14 and the sheath 15, the bottom end of the push rod 10 is directly used to block the pilot hole 91 in the middle of the valve core 9, and the top end is directly located under the shrapnel 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com