Conveying device for sensor production

A conveying device and sensor technology, which is applied in the field of conveying devices for sensor production, can solve the problems of inconvenient movement and fixation of the conveying device, low degree of automation of the conveying device, and easy vibration, etc. The effect of small vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

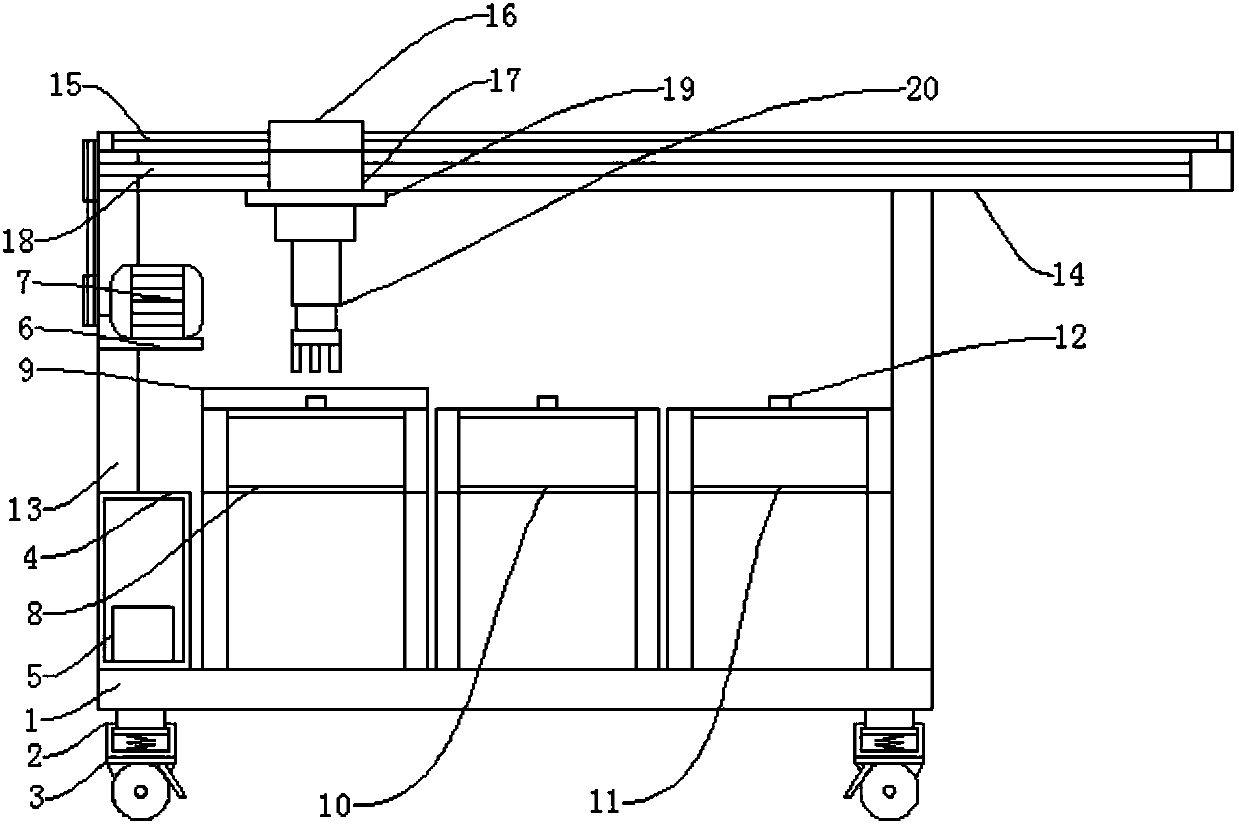

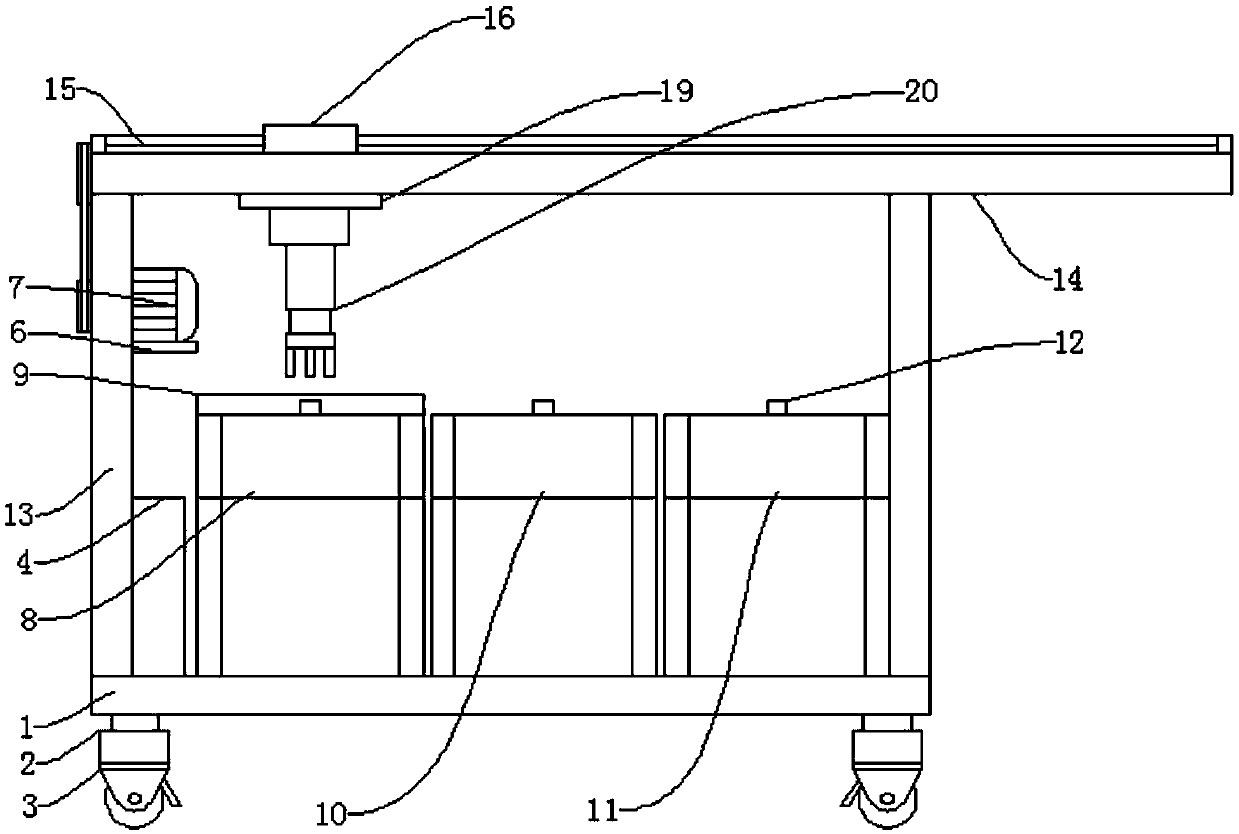

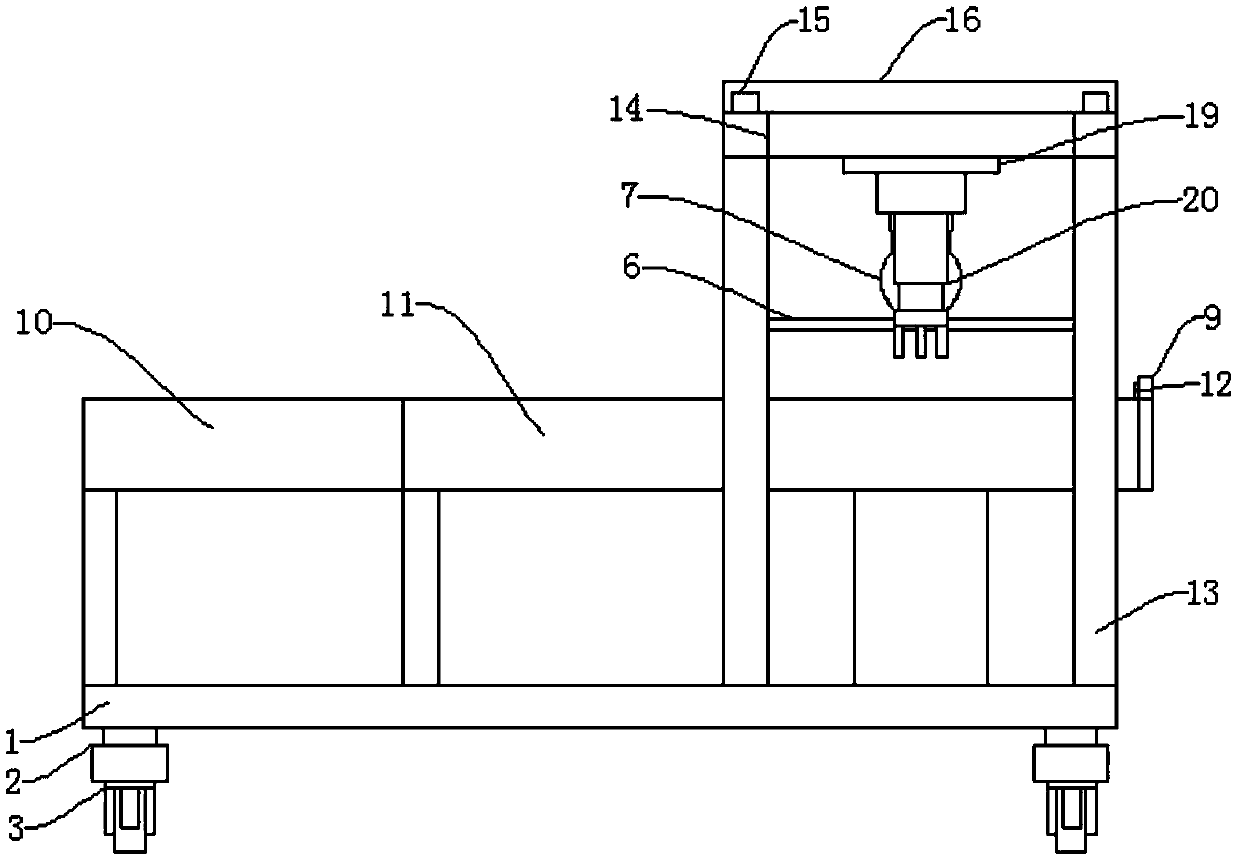

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] Such as Figure 1-Figure 5 As shown, a conveying device for sensor production includes a bottom frame 1, a shock-absorbing support leg 2, a column 13, and a top frame 14. A shock-absorbing support leg 2 is arranged under the bottom frame 1, and the shock-absorbing support leg 2 is used for shock absorption. Support, shock absorption The universal brake wheel 3 is set under the support leg 2, the universal brake wheel 3 is used for device movement, the control box 4 is set above the bottom frame 1, the control box 4 is used to protect the internal device, and the control box 4 is set inside There is a controller 5, the model of which is KY02S, which is used to control the operation of the device. There is a support plate 6 above the control box 4. The support plate 6 is used to support the motor 7. The motor 7 is arranged above the support plate 6. The motor 7 is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com