Square material cover separating and buckling machine

A capping machine and material technology, which is applied in packaging and other directions, can solve the problems of difficulty in ensuring hygienic conditions and low efficiency, and achieve the effect of ingenious and reliable structure, convenient control, and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

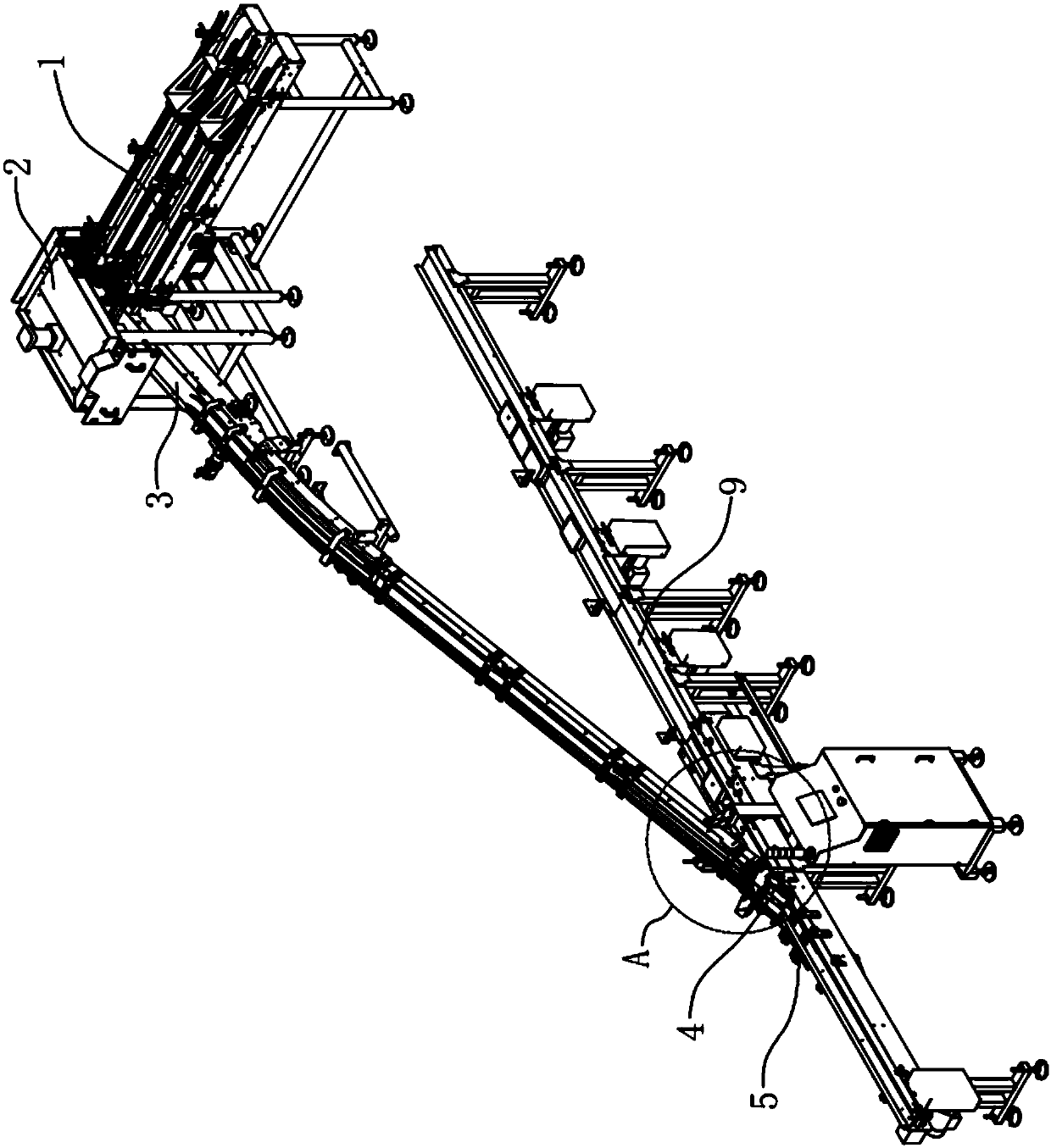

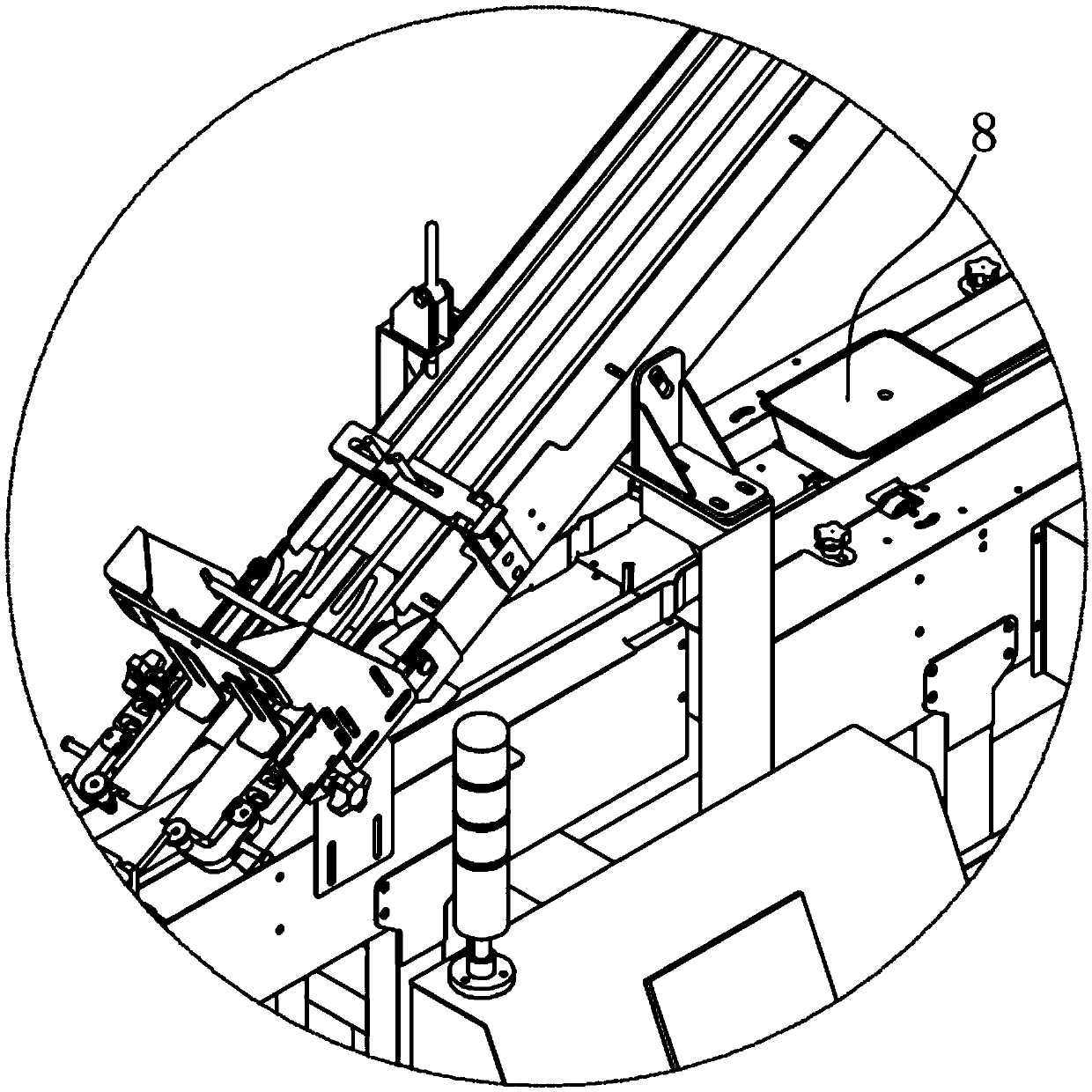

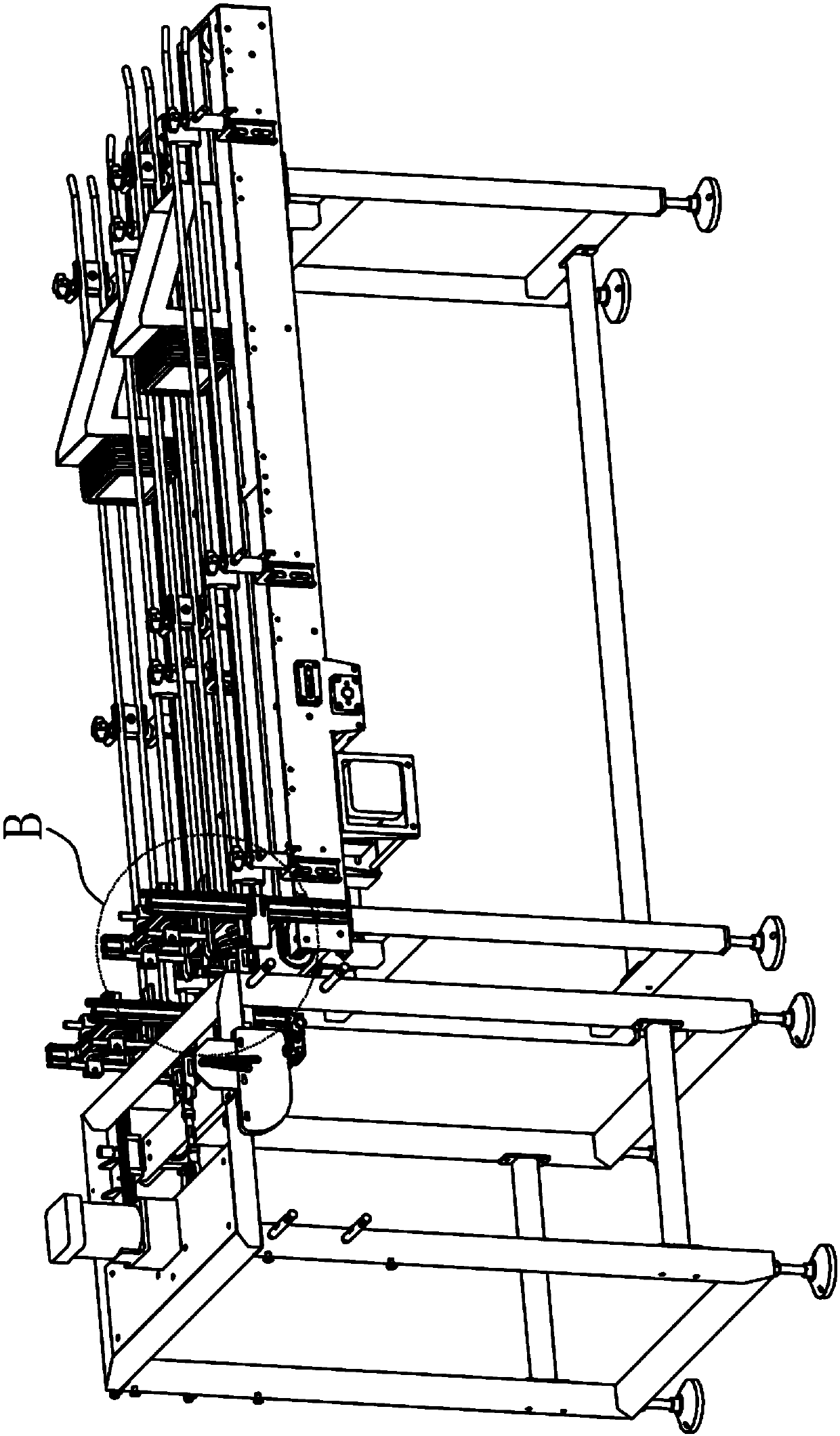

[0039] In order to achieve the purpose of the present invention, a square material capping and capping machine includes: a cap feeding mechanism 1, which feeds the stacked caps 7; a cap discharging mechanism 3, which feeds the stacked caps 7 Discharge one by one; the box body feeding mechanism 9, the opening of the box body 8 faces upwards and conveys horizontally, the cover body discharging mechanism 3 and the box body feeding mechanism 9 are arranged at an angle and meet; the buckle cover mechanism 4 is arranged on the cover body At the intersection of the discharge mechanism 3 and the box body material transfer mechanism 9, the button cover mechanism 4 includes a downward pressing shrapnel 405 and a cover wheel 407, and the cover wheel 407 is located on both sides by a pair of swing arms 408, and the cover wheel 407 Possess a pincer-shaped opening and clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com