Medical vehicle

A medical car and shell technology, applied in the field of medical car, can solve the problems of one-way pulling, unfavorable accessories, short life, etc., and achieve the effect of facilitating the placing and taking out, slowing down the corrosion rate, and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

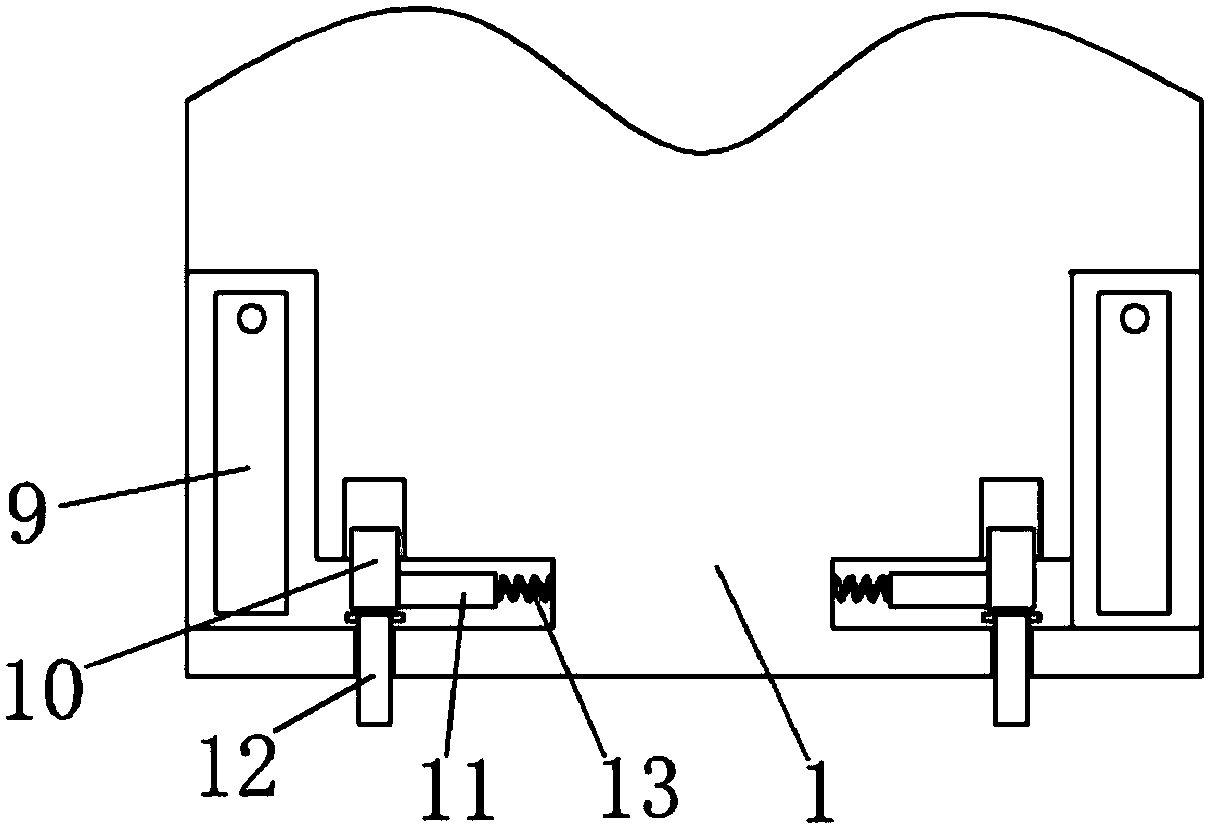

[0033] The following is attached Figure 1-4 The present invention will be described in further detail.

[0034] A medical vehicle includes a medical vehicle housing 1. A partition is horizontally arranged inside the medical vehicle housing 1, and the side wall of the partition is vertically fixedly connected with the middle of the inner wall of the medical vehicle housing 1, and both the upper and lower sides of the partition are provided with carrying boxes 2. The two sides of the carrying box 2 are movably connected with the inner wall of the medical vehicle housing 1. The lower side of the medical vehicle housing 1 is fixed with a pulley 8. Both side walls of the medical vehicle are provided with vertical grooves. The support rod 9 is movably connected to the side wall of the vertical slot through a pin on both sides of the upper end of the support rod 9. A recovery box 14 is provided under the storage box 2, and the recovery box 14 is detachably connected to the chassis of t...

Embodiment 2

[0043] The difference from Example 1 is that the storage box 2 is coated with an anti-rust layer, and the preparation method of the anti-rust layer is:

[0044] Take the following raw materials by weight: 1 part of fumed white carbon black, 10 parts of iron powder, 20 parts of titanium dioxide, 22.5 parts of water-based fluorocarbon resin, 8 parts of copper powder, 5 parts of kaolin, and 15 parts of phenolic resin.

[0045] S1. Prefabricated organic solvent: mix water-based fluorocarbon resin and phenolic resin, heat to 45°C, and stir evenly;

[0046] S2, prepare anti-rust paint; add kaolin, titanium dioxide, fumed white carbon black, iron powder, and copper powder to the organic solvent in S1 in sequence, and stir evenly;

[0047] S3. Treatment: Ultrasonic treatment of the anti-rust paint made by S2 for 0.5, then cool to room temperature, stir at 1200r / min for 0.5h, and then stand;

[0048] S4. Coating: The anti-rust paint obtained in S3 is evenly coated on the surface of the storage b...

Embodiment 3

[0052] The difference from Example 2 is that the formula specific gravity of the anti-rust layer is improved and re-coated on the storage box 2. The preparation method of the anti-corrosion layer is:

[0053] Take the following raw materials by weight: 2 parts fumed white carbon black, 12 parts iron powder, 30 parts titanium dioxide, 27.5 parts water-based fluorocarbon resin, 20 parts copper powder, 8 parts kaolin, and 25 parts phenolic resin.

[0054] S1. Prefabricated organic solvent: mix water-based fluorocarbon resin and phenolic resin, heat to 45°C, and stir evenly;

[0055] S2, prepare anti-rust paint; add kaolin, titanium dioxide, fumed white carbon black, iron powder, and copper powder to the organic solvent in S1 in sequence, and stir evenly;

[0056] S3. Treatment: Ultrasonic treatment of the anti-rust paint made by S2 for 0.5, then cool to room temperature, stir at 1200r / min for 0.5h, and then stand;

[0057] S4. Coating: The anti-rust paint obtained in S3 is evenly coated on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com