A Monitoring Method of Baffle Lifting Height Based on Image Processing

An image processing and image processor technology, which is applied in image communication, color TV parts, TV system parts, etc., can solve the problems of industrial control errors of detection data, complex and cumbersome detection technology, production accidents, etc., and achieve structural Simple, high discrimination rate, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

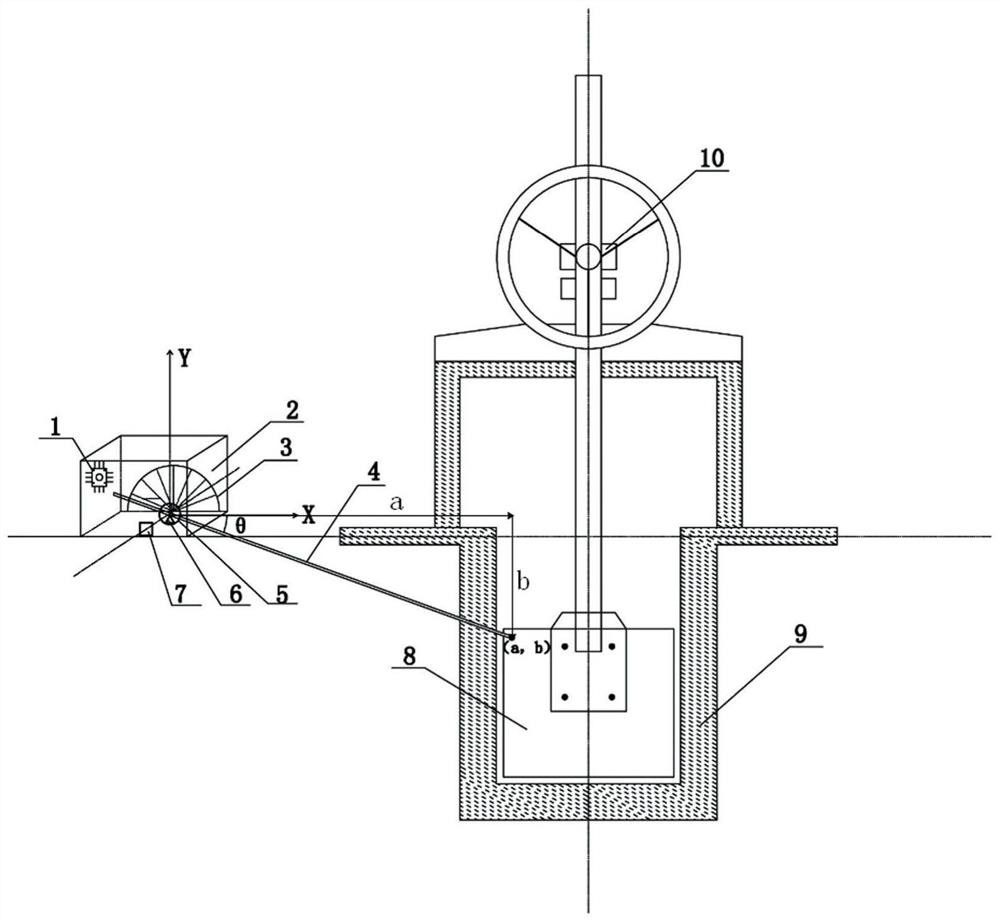

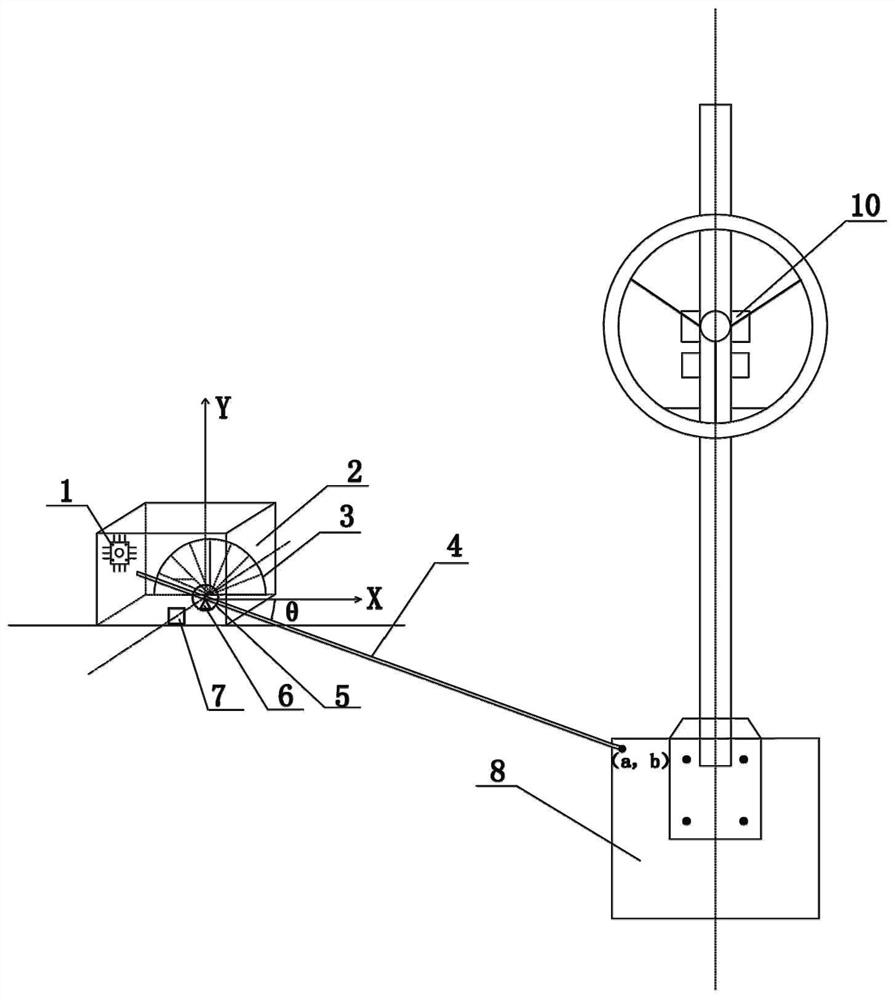

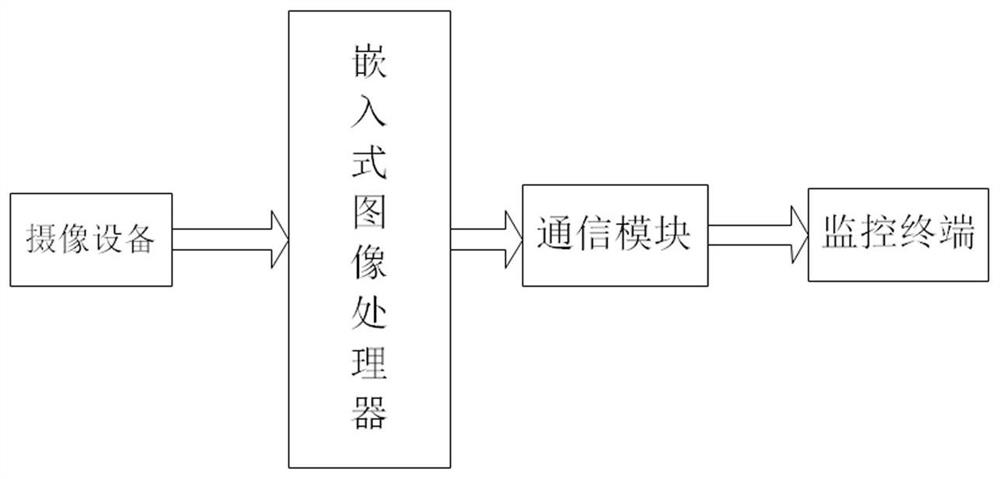

[0028] Such as figure 1 figure 2 and image 3 As shown, a monitoring device for the lifting height of the baffle plate based on image processing of the present invention includes a baffle plate 8 arranged at the ore outlet 9 of the mine bin, and the baffle plate 8 is driven by the baffle plate drive motor 10 to make it vertically up and down. Movement, characterized in that: a monitoring device for the lifting height of the baffle is provided on the working platform of the ore outlet 9 of the mine bin, and the monitoring device for the lifting height of the baffle includes a box body 2 and a scale arranged in the box body 2 Disk 3, connecting rod lifting device, high-definition camera equipment 7 and monitoring system, said dial 3 is arranged in the rear part of the box body 2, and the central axis of the box body 2 passes through the center of the dial 3 vertically; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com