Missile wing quick disassembling structure

A technology of wings and main lugs, which is applied in the direction of projectiles, offensive equipment, weapon types, etc., can solve the problems of complex connection relationship, inability to meet quick disassembly, inconvenient disassembly and assembly, and meet the requirements of interchangeability and simple structure , The effect of reducing the time of assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

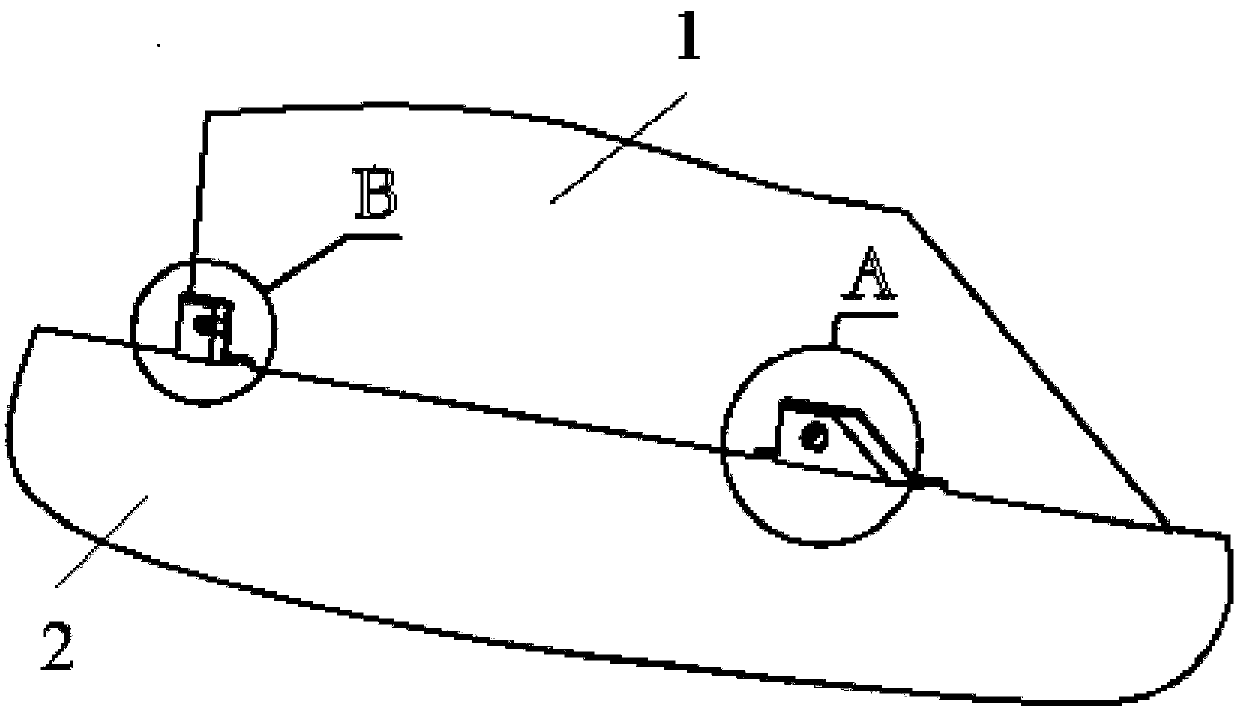

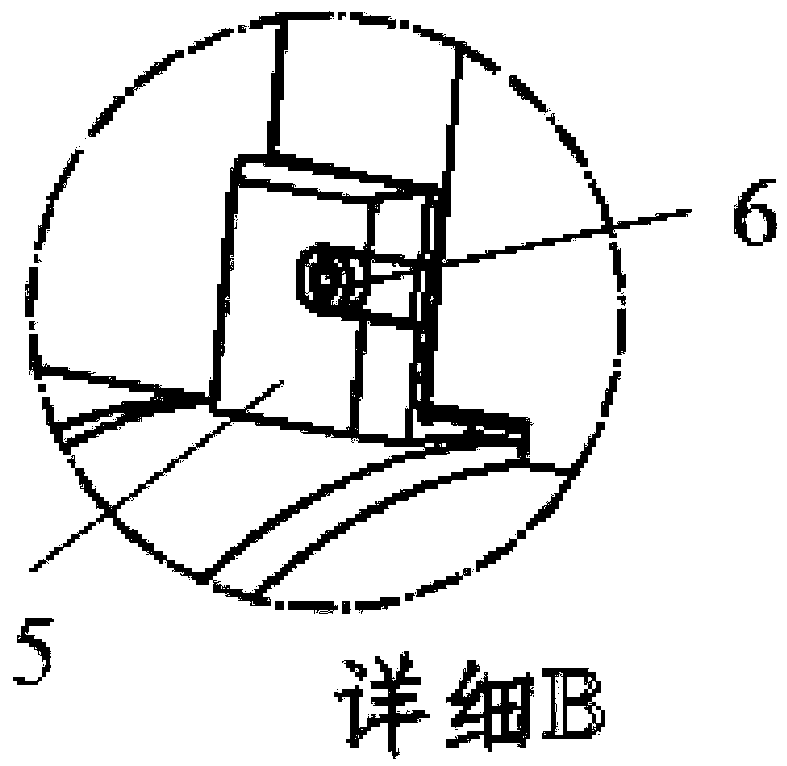

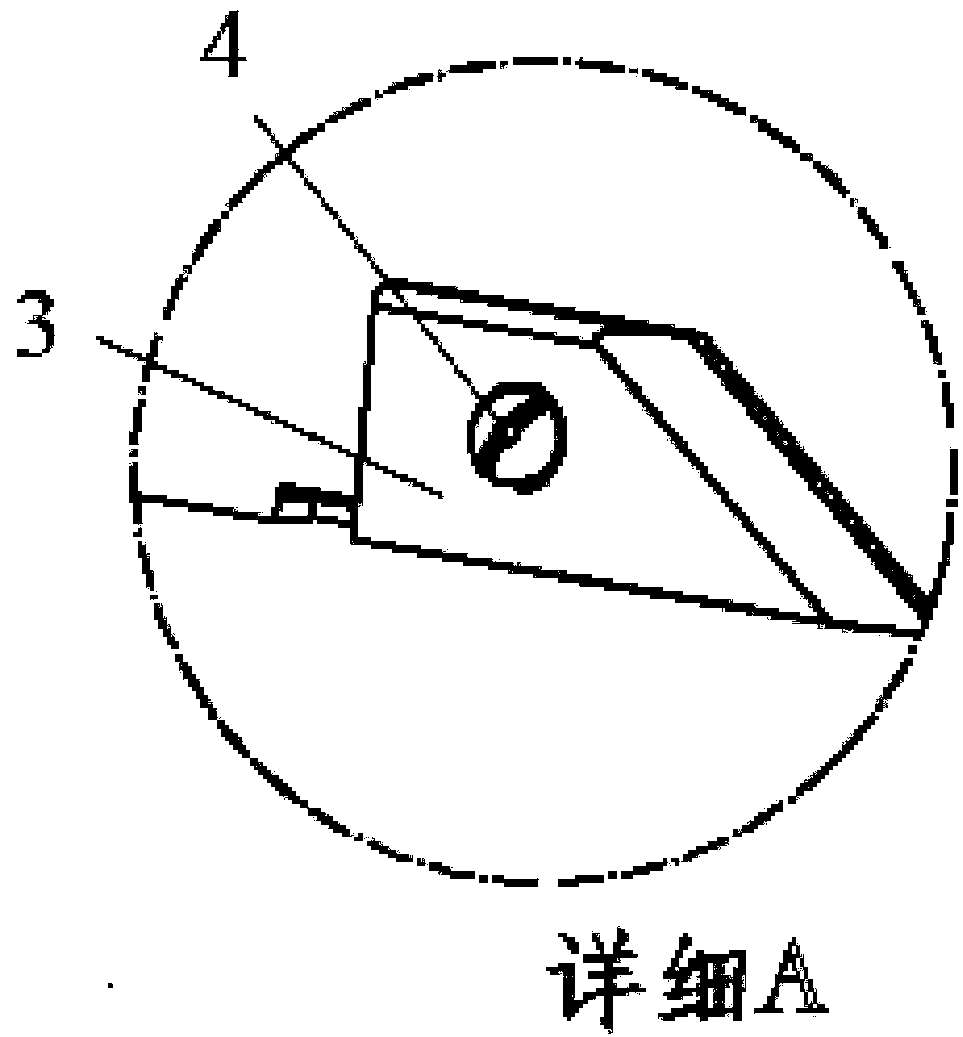

[0024] Such as figure 1 -2, the wing quick release structure of the present invention is characterized in that it includes self-made bolts and nuts 6, main lugs 3, auxiliary lugs 5 and locking screws 4;

[0025] Wherein, the main ear piece 3 and the auxiliary ear piece 5 are arranged on the missile cabin body 2, the main ear piece 3 is located at the front part of the auxiliary ear piece 5, and a U-shaped positioning groove is opened at the front end of the auxiliary ear piece 5;

[0026] The matching surface 9 of the main lug and the matching surface 7 of the auxiliary ear are set on the position corresponding to the main lug 3 and the auxiliary lug 5 on the wing 1; the matching surface 7 of the auxiliary lug has a positioning hole 8, and before the wing 1 is installed, Tighten the self-made bolts and nuts 6 on both sides of the auxiliary lug mating surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com