Automatic lifting type electronic rotary knob gear shifter assembly

An automatic lifting and shifter technology, which is applied in the direction of transmission control, components with teeth, belts/chains/gears, etc., can solve the problems of rigid button operation, poor operation experience, and large space occupation, and achieve high-end High reliability, comfortable operation feel, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

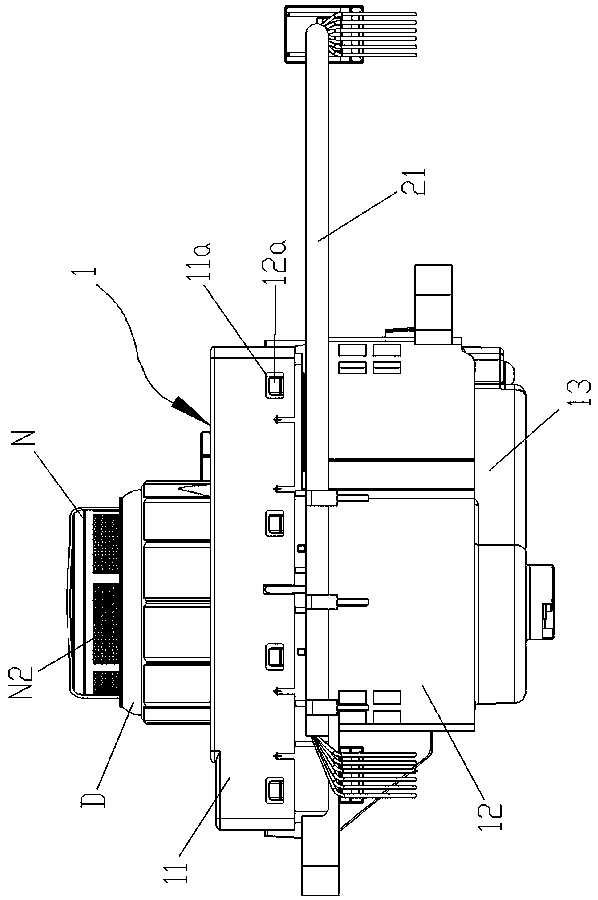

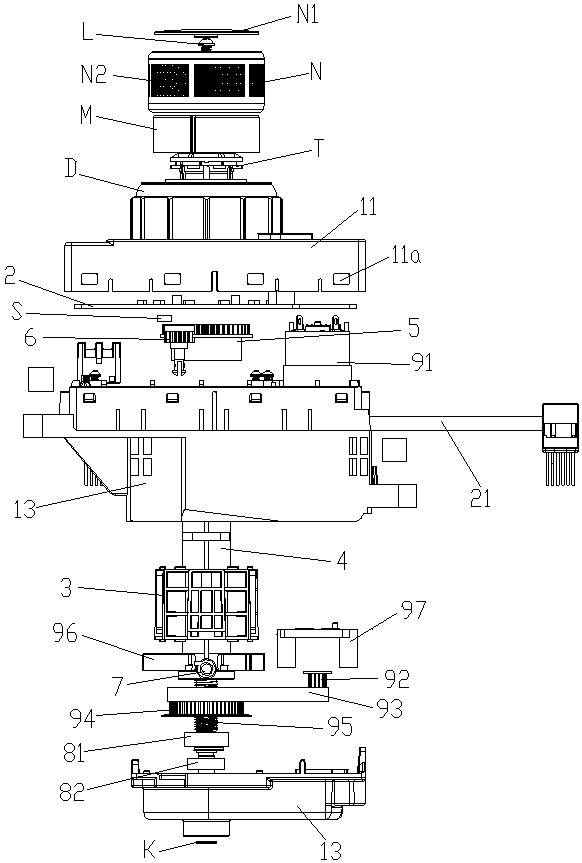

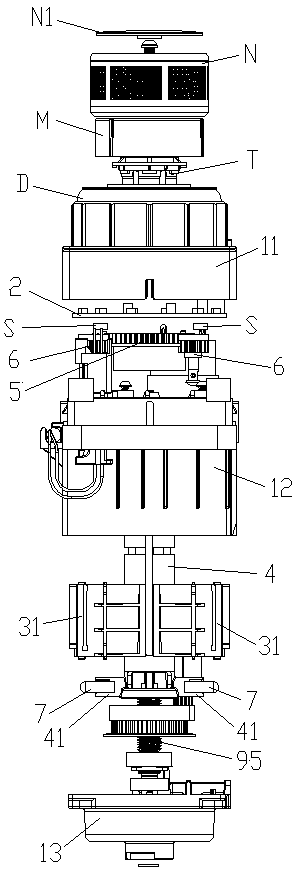

[0030] Figures 1 to 10 It is a structural representation of the present invention.

[0031] The reference signs are: light guide ring D, retaining spring K, knob screw L, inner cover M, knob N, knob cover N1, anti-skid pattern N2, magnet S, shrapnel cover T, shifter housing 1, upper housing 11. Buckle window 11a, middle shell 12, buckle head 12a, buckle cavity 12b, lower shell 13, buckle claw 13b, PCB board 2, wiring harness 21, curved surface block 3, guide chute 3a, return groove 3b, Gear slot 3c, soft rubber layer 3d, curved surface block unit 31, V-shaped opening cavity 32, limit block 33, positioning block 34, protrusion 35, lifting rod 4, hollow rod cavity 4a, gear pin assembly Hole 4b, guide rod hole 4c, guide cylinder 41, gear gear 5, signal gear 6, rotating shaft 61, anti-off chuck 62, elastic deformation gap 62a, gear pin 7, large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com