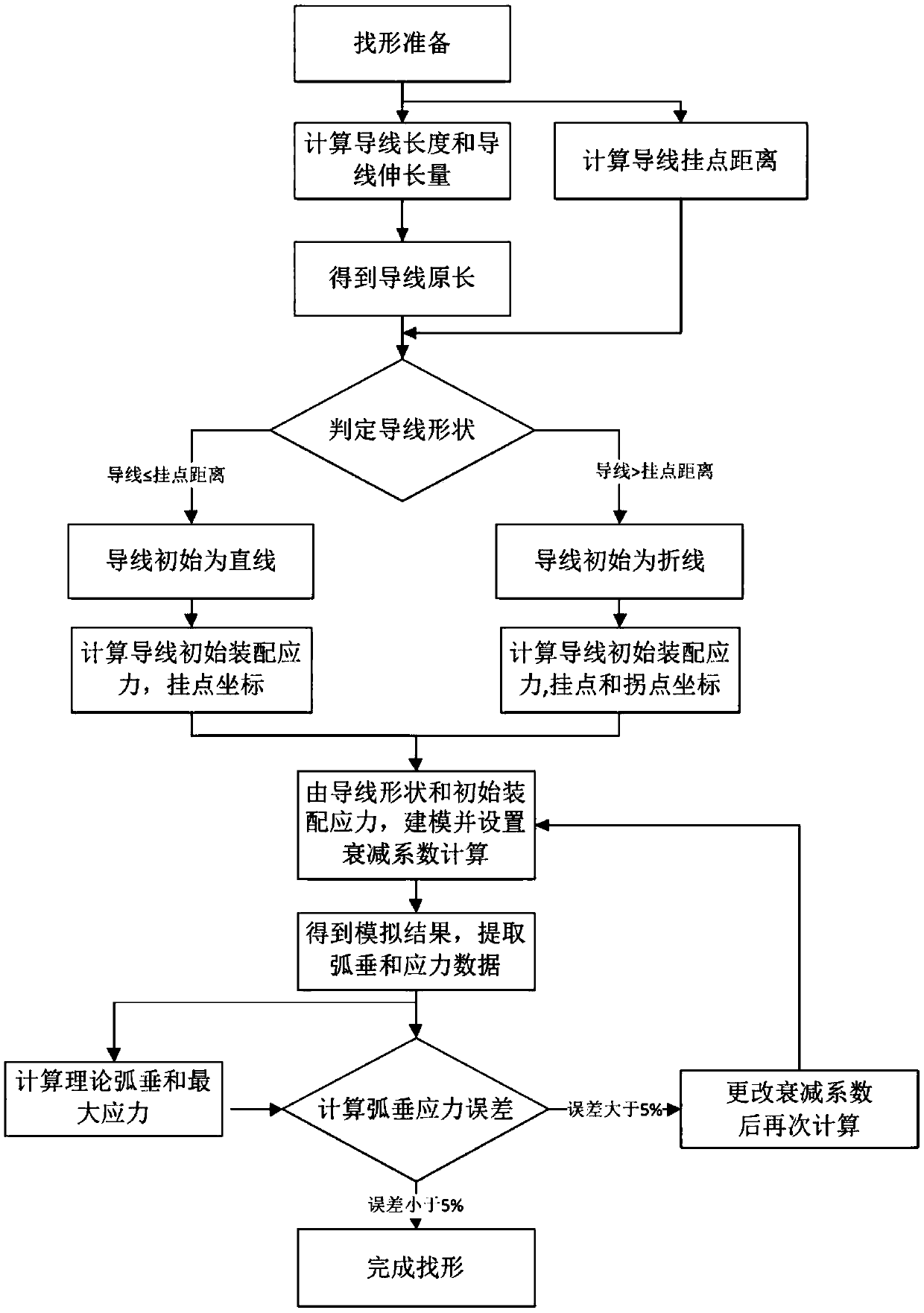

An overhead conductor shape finding method based on ABAQUS finite element software

An overhead wire and finite element technology, applied in geometric CAD, special data processing applications, instruments, etc., can solve the problems of limited use of prefabricated model update method, low calculation accuracy, poor operability, etc., and achieve stable calculation results , good operability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

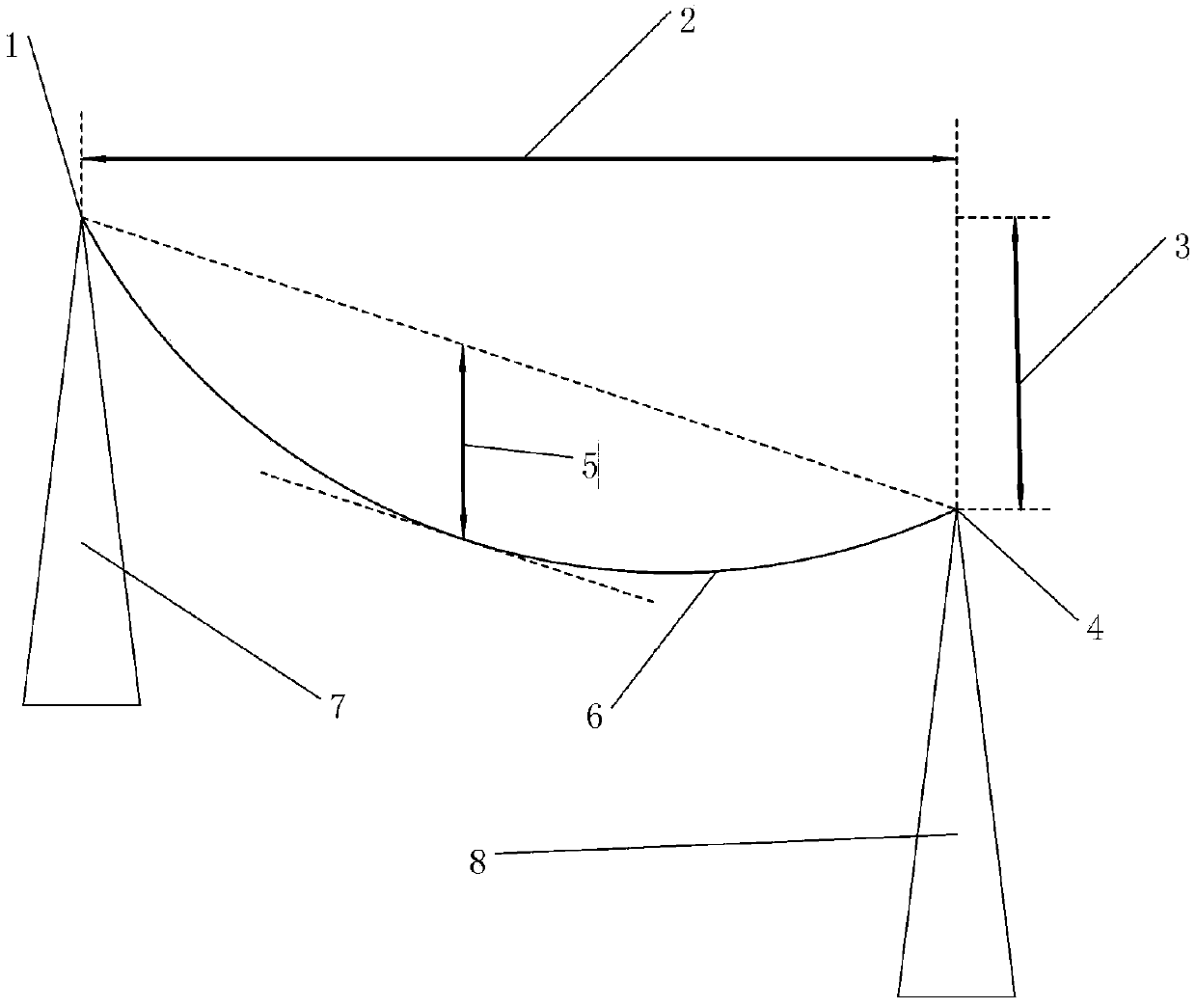

[0151] Such as figure 2 As shown, there is an existing wire model, and its specific data are, elastic modulus E=55GPa, diameter 26.81mm, and cross-sectional area 426.28mm 2 , with a self-weight of 1.18kg / m, it is now installed between two towers with a span of 300m and no height difference. The horizontal stress during installation is 30Mpa. Analyze and calculate the shape and internal force of the wire.

[0152] Detailed process:

[0153] Calculate the required parameters

[0154]

[0155] Among them, h 0 is the catenary equation parameter determined by the wire properties, σ 0 is the horizontal stress under the gravity of the conductor,

[0156] A is the cross-sectional area of the wire, p is the mass per unit length of the wire, and g is the acceleration due to gravity;

[0157] Calculate the curve left endpoint, right endpoint

[0158]

[0159] l b =l+l a =150

[0160] Among them, l a is the abscissa of the left endpoint of the wire, l b is the abscissa...

Embodiment 2

[0182] There is a wire model, the specific data is, elastic modulus E=55GPa, diameter 26.81mm, cross-sectional area 426.28mm 2 , with a self-weight of 1.18kg / m, it is now installed between two towers with a span of 300m and a height difference of 50m. The horizontal stress during installation is 55.1Mpa. Analyze and calculate the shape and internal force of the wire.

[0183] Detailed process:

[0184] Calculate the required parameters

[0185]

[0186] Among them, h 0 is the catenary equation parameter determined by the wire properties, σ 0 is the horizontal stress of the conductor under gravity, A is the cross-sectional area of the conductor, p is the mass per unit length of the conductor, and g is the acceleration due to gravity;

[0187] Calculate the curve left endpoint, right endpoint

[0188]

[0189] l b =l+l a =-186.6710

[0190] Among them, l a is the abscissa of the left endpoint of the wire, l b is the abscissa of the right end of the wire, l is th...

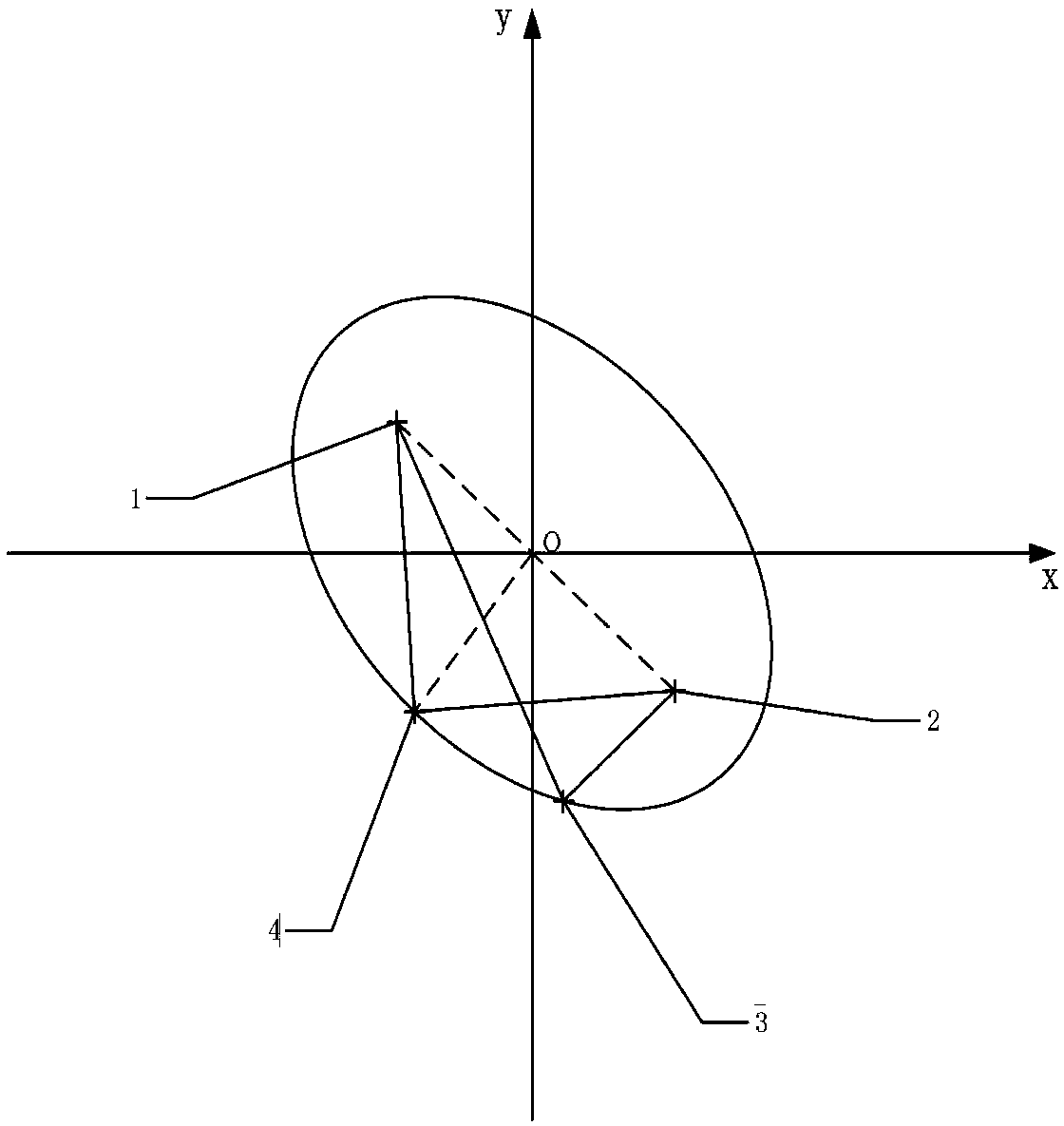

Embodiment 3

[0212] There is a wire model, the specific data is, elastic modulus E=55GPa, diameter 26.81mm, cross-sectional area 426.28mm 2 , with a self-weight of 1.18kg / m, it is now installed between two towers with a span of 300m and no height difference, and the horizontal stress during installation is 30Mpa. Analyzing and calculating the shape and internal force of the wire, this embodiment 3 is the same as the embodiment 1, but the coordinates of the inflection point are changed.

[0213] Detailed calculation process:

[0214] Calculate the required parameters

[0215]

[0216] Among them, h 0 is the catenary equation parameter determined by the wire properties, σ 0 is the horizontal stress of the conductor under gravity, A is the cross-sectional area of the conductor, p is the mass per unit length of the conductor, and g is the acceleration due to gravity;

[0217] Calculate the curve left endpoint, right endpoint:

[0218]

[0219] l b =l+l a =150

[0220] Among the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com