Multi-channel optical cable bundling tube

A bundled tube and multi-channel technology, applied in the field of bundled tubes, can solve the problems of poor lubrication effect, large friction between optical cables and pipes, etc., and achieve the effects of preventing offset, enhancing the ability to resist stretching, and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

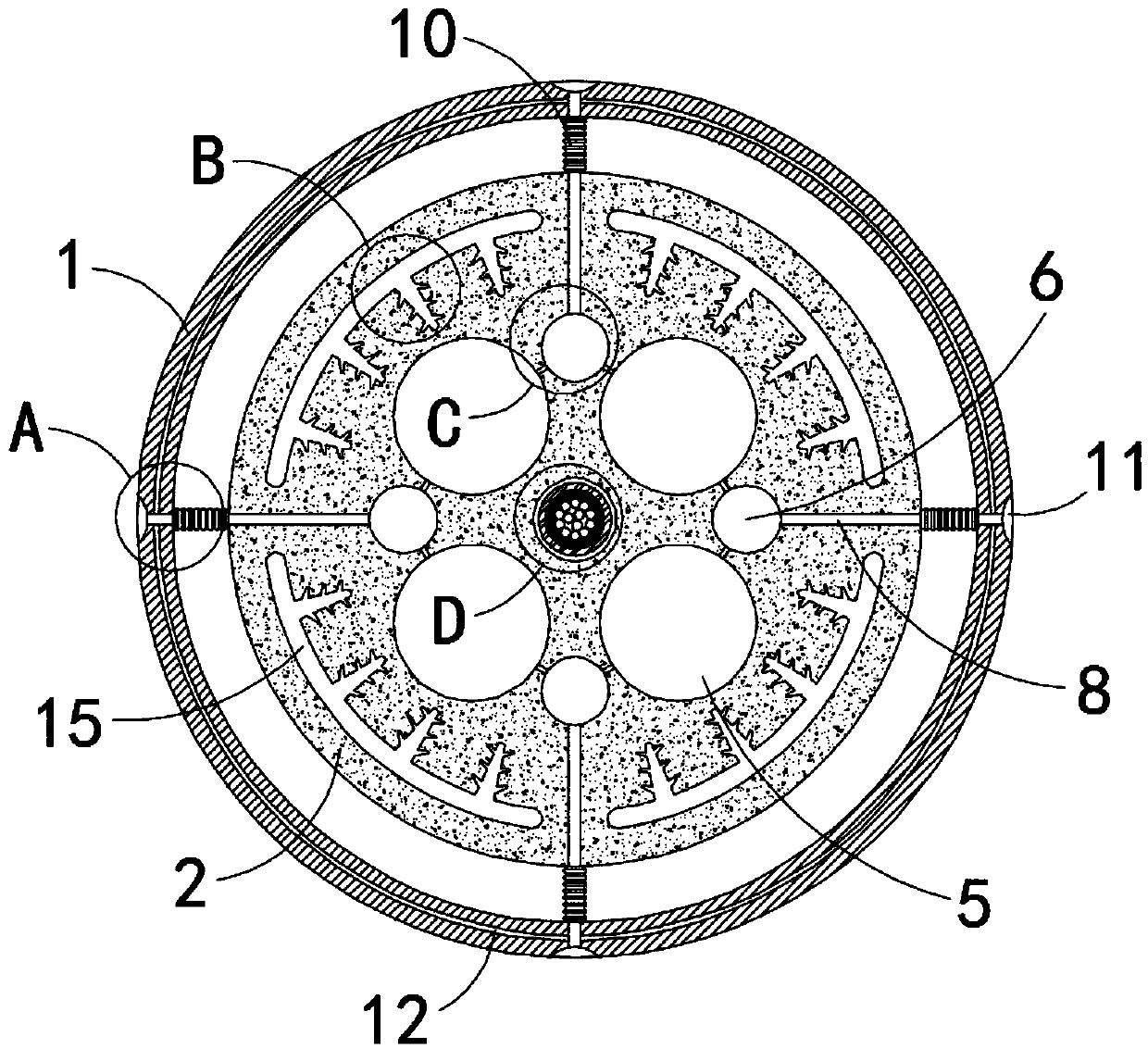

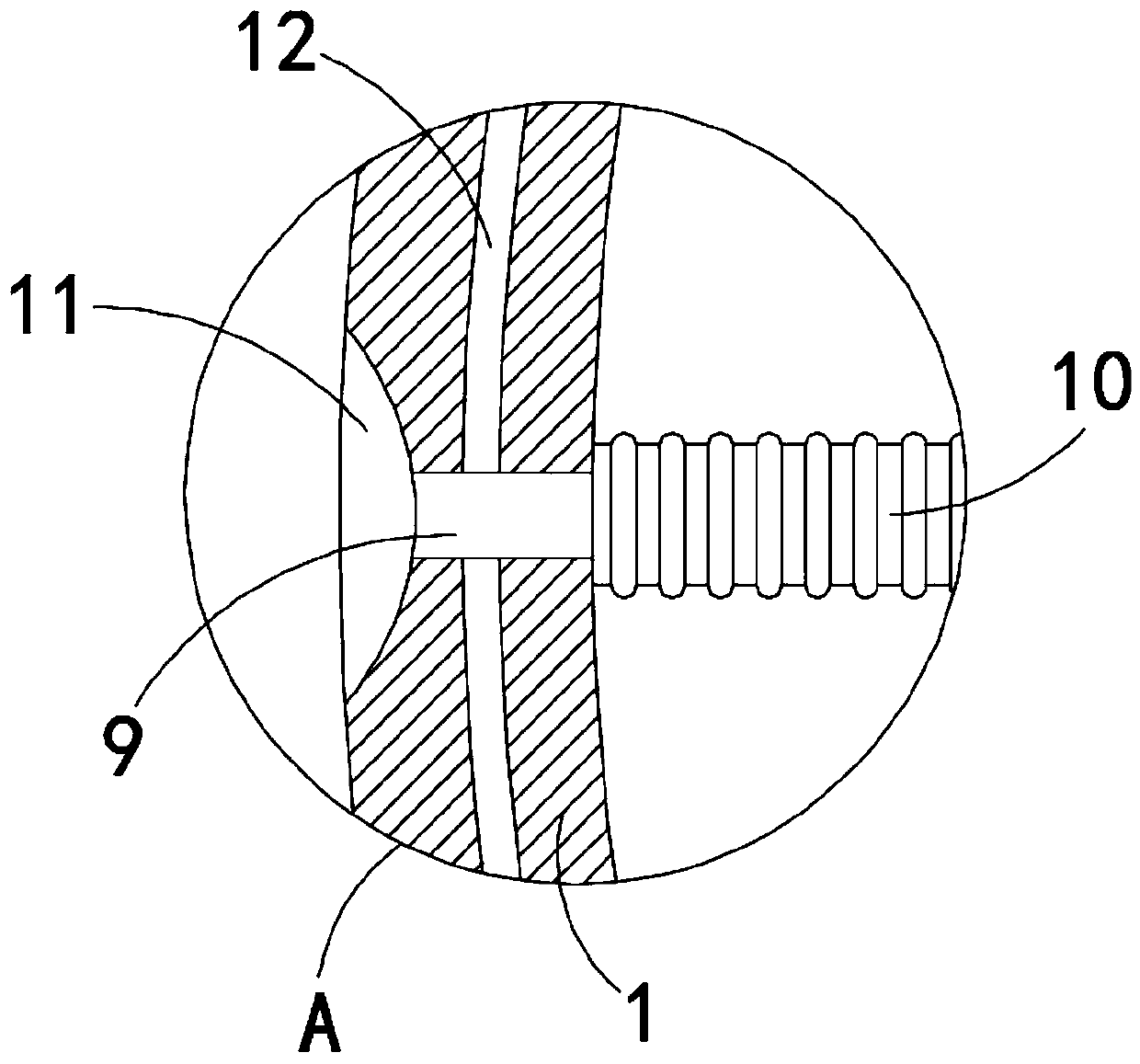

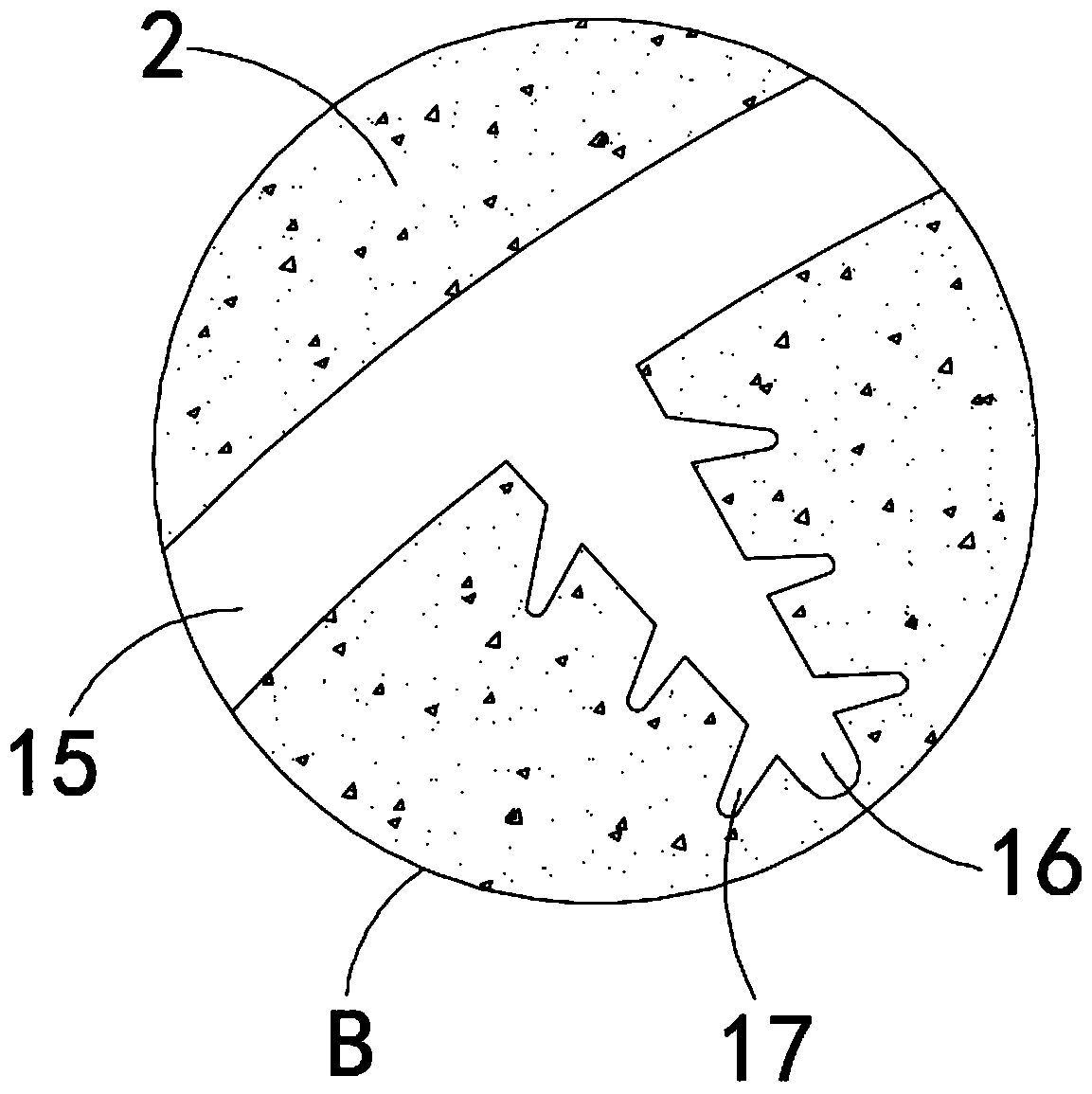

[0031] Such as Figure 1-7 As shown, a multi-channel optical cable bundle tube includes a protective cover 1, and a solid cylindrical body 2 is arranged inside the protective cover 1. Both the protective cover 1 and the solid cylindrical body 2 can be made of rubber, and the center of the solid cylindrical body 2 is along its A reinforcement cavity 3 is provided in the axial direction, and the reinforcement cavity 3 is arranged coaxially with the columnar body 2. A tensile tube 4 is provided in the reinforcement cavity 3. The outer wall of the tensile tube 4 is in contact with the inner wall of the reinforcement cavity 3, and the reinforcement cavity 3 is reinforced. A plurality of optical cable placement cavities 5 are evenly distributed around the cavity 3, and the plurality of optical cable placement cavities 5 take the reinforcement cavity 3 as a uniform part of the center. An infusion channel 7 communicates with the optical cable placement cavity 5, the diameter of the in...

Embodiment 2

[0042] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that: the gap between the solid columnar body 2 and the protective cover 1 is filled with a non-Newtonian liquid 18, and the non-Newtonian liquid 18 is a fluid that does not satisfy a linear relationship. It has the characteristics of "when you meet the strong, you are strong, and when you meet the weak, you are weak".

[0043] By filling the gap between the solid cylindrical body 2 and the protective sheath 1 with a non-Newtonian liquid 18, when the optical cable is hit or beaten by an external force, it will produce a relatively strong hardness and improve the compression and impact resistance of the bundle tube. The cluster tubes play a protective role.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com