A tri-gate component and an ion source containing the tri-gate component

A component and inner grid technology, applied in the field of low-energy and wide-beam extraction conditions, can solve problems such as increased equipment costs, grid deformation, and complex structures, and achieve the effects of reducing equipment manufacturing costs, reducing size, and avoiding deformation and short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

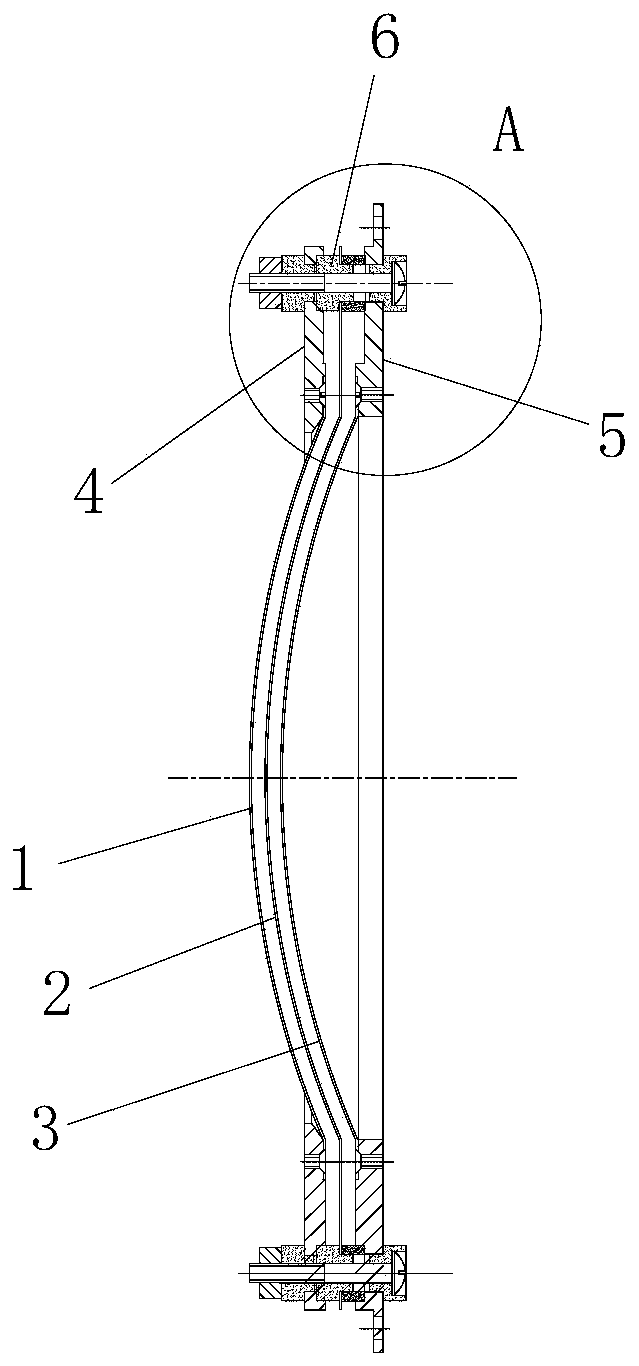

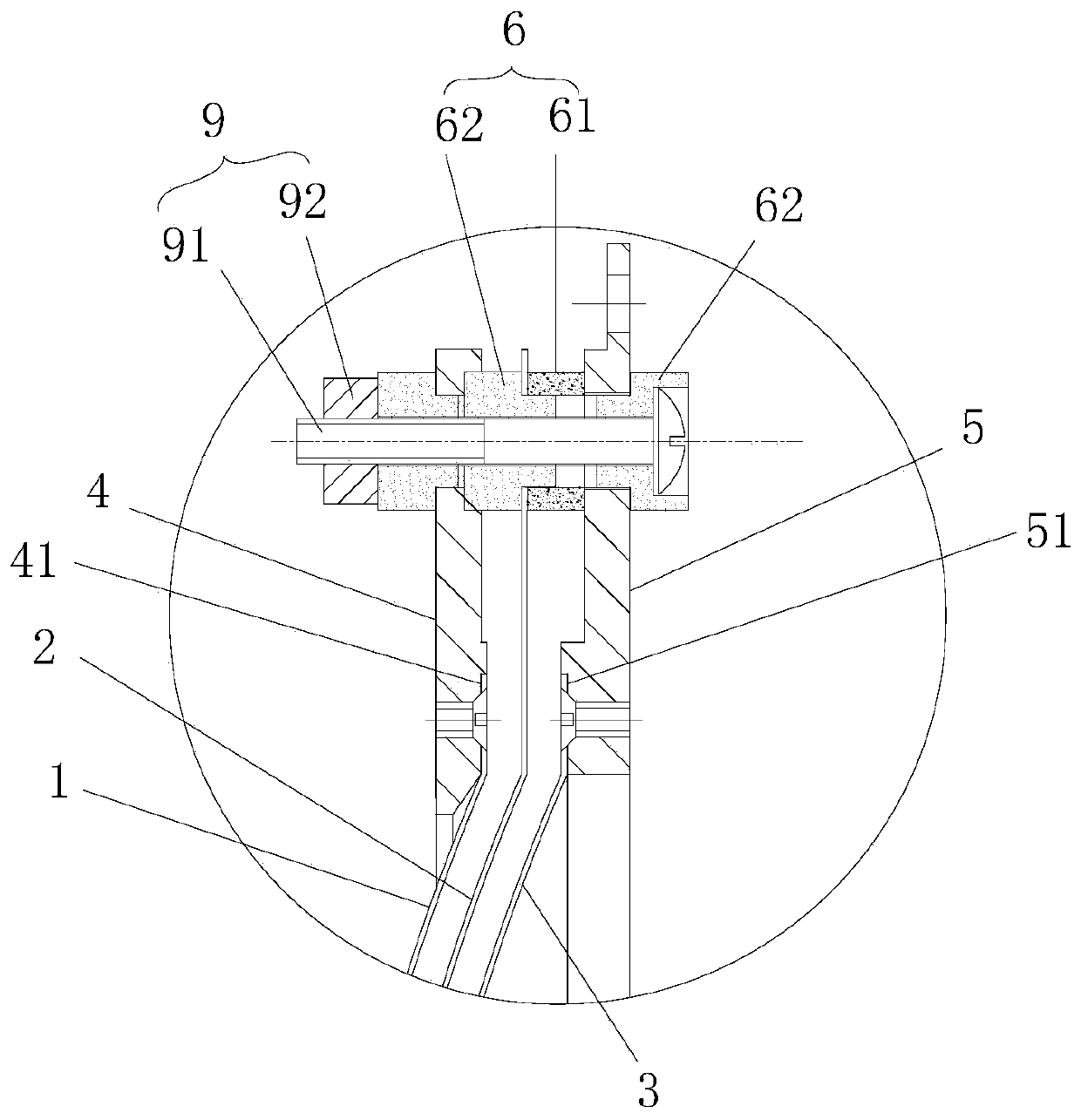

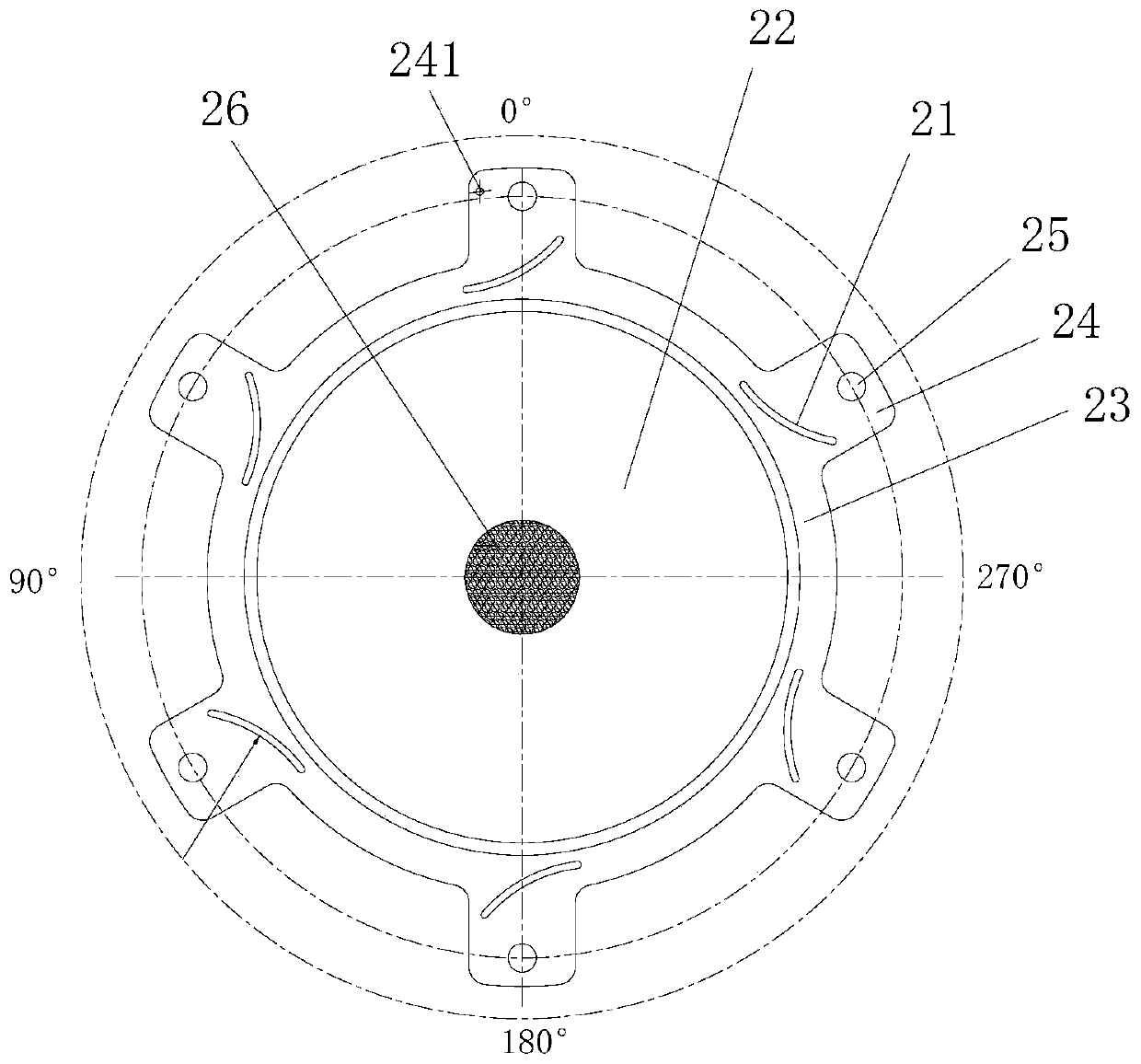

[0025] Figure 1 to Figure 3 An embodiment of the three-grid assembly of the present invention is shown. The three-grid assembly of the present embodiment includes an inner grid 1, a middle grid 2 and an outer grid 3 arranged in parallel in sequence, and the inside of the inner grid 1 (accompanying drawing) The left side in the middle) is provided with an inner flange 4, the inner grid 1 is installed on the inner flange 4, and the outer grid 3 (right side in the drawing) is provided with an outer flange 5, and the outer grid 3 is installed on the On the outer flange 5, between the inner flange 4 and the middle grid 2, and between the outer flange 5 and the middle grid 2, insulating spacers 6 are sandwiched, and the insulation spacers 6 are used to connect the gaps between the grids. Insulated and isolated, the grid 2 is provided with a stress absorbing groove 21 for absorbing thermal deformation. Preferably, the insulating spacer 6 can be a combination of a T-shaped insulatin...

Embodiment 2

[0033] Figure 4 An embodiment of the ion source of the present invention is shown. The ion source of this embodiment includes an inner cover 7, a discharge chamber 8 located inside the inner cover 7, and an anode 10 and a cathode 20 located in the discharge chamber 8, and also includes In the above-mentioned three-bar assembly, the inner flange 4 in the three-bar assembly is in close contact with the discharge chamber 8 to ensure that the inner grid 1 is at a high potential during operation, and the outer flange 5 in the three-bar assembly is connected to the inner cover 7 to ensure that the working , the outer flange 5 and the inner cover 7 are at ground potential.

[0034] The ion source of the present invention contains the above-mentioned tri-grid assembly, so it also has the above-mentioned advantages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com