Water spraying belt punching machine

A technology for punching machines and water spray belts, which is applied in the field of punching machines and can solve problems such as uneven punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

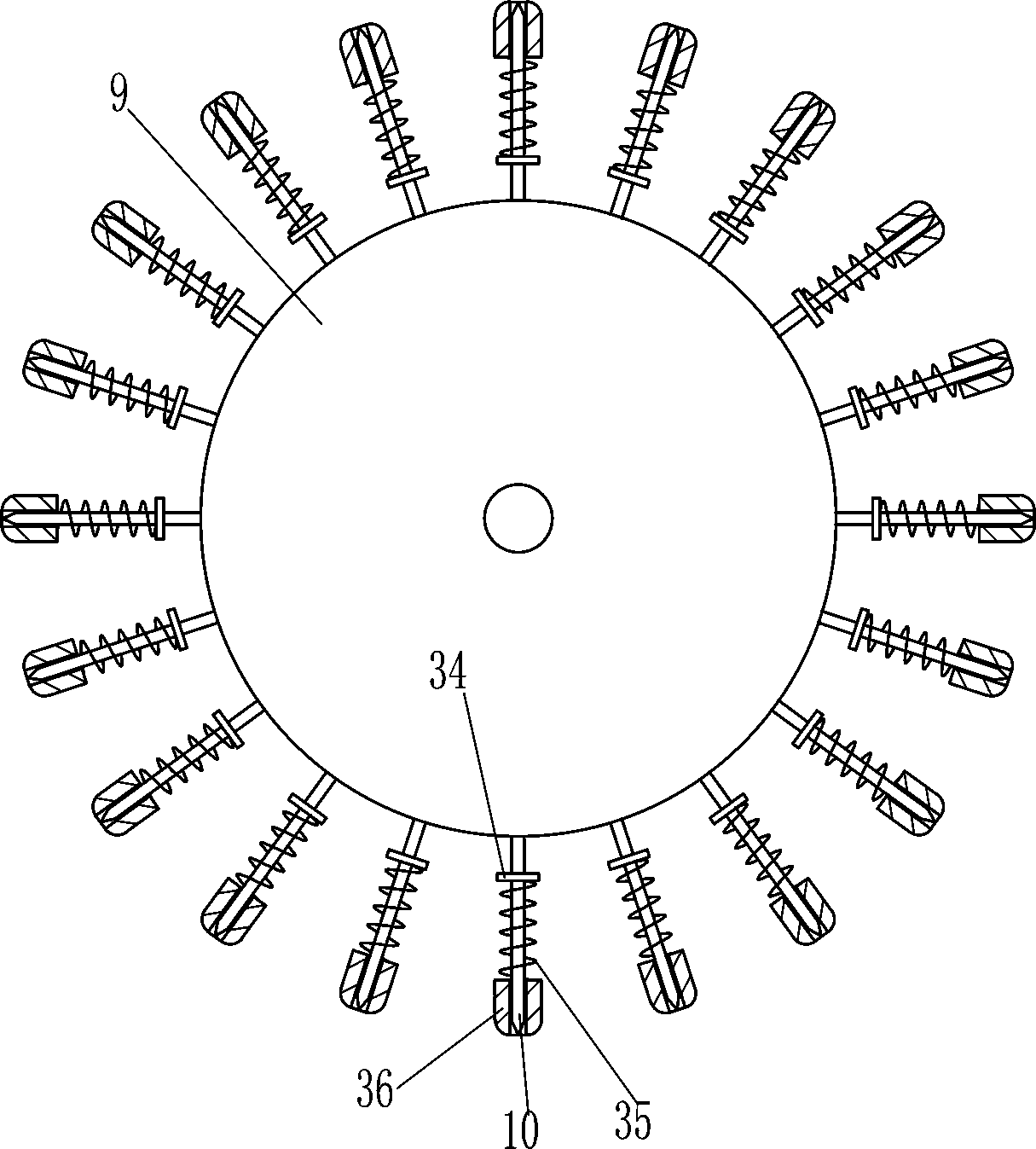

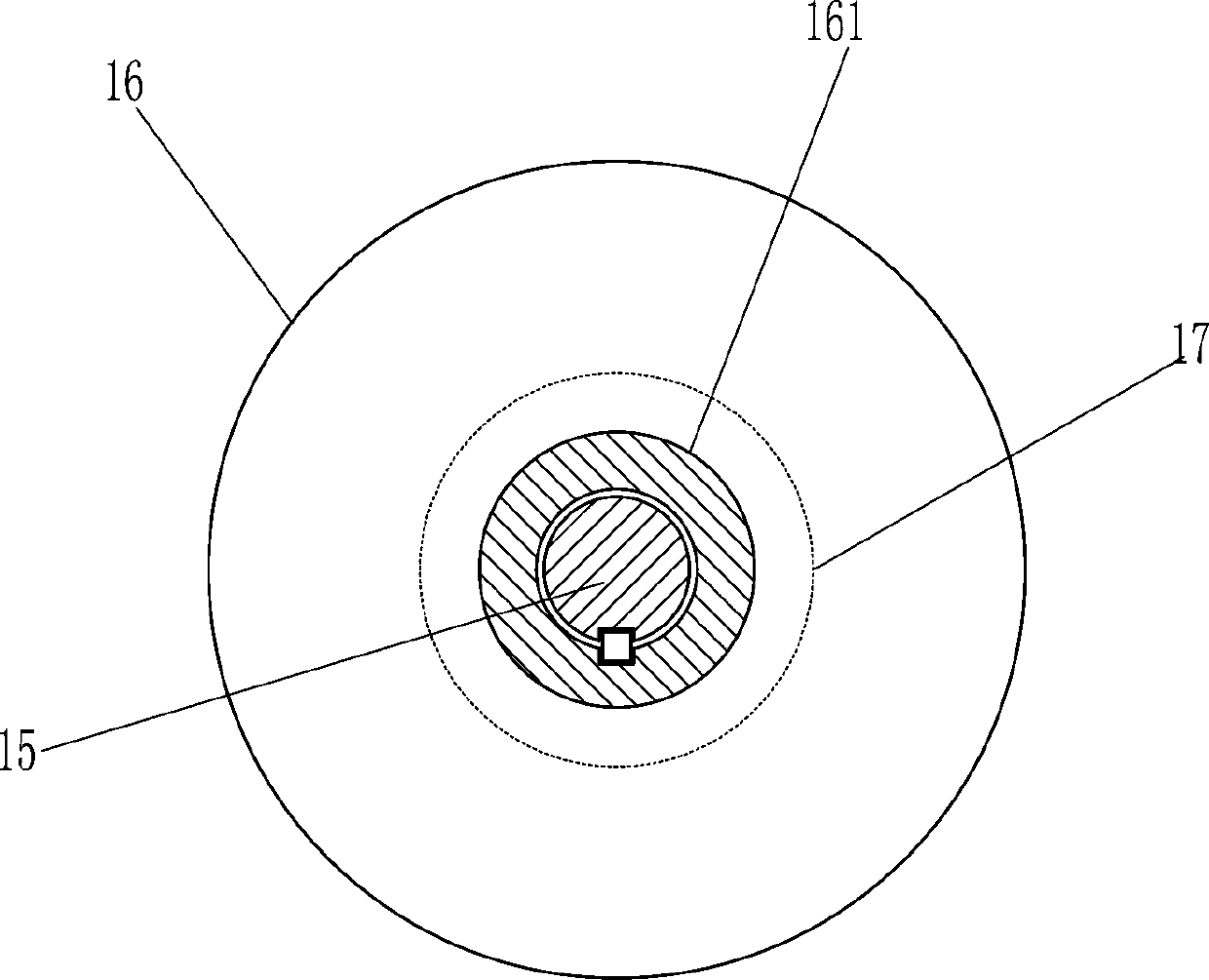

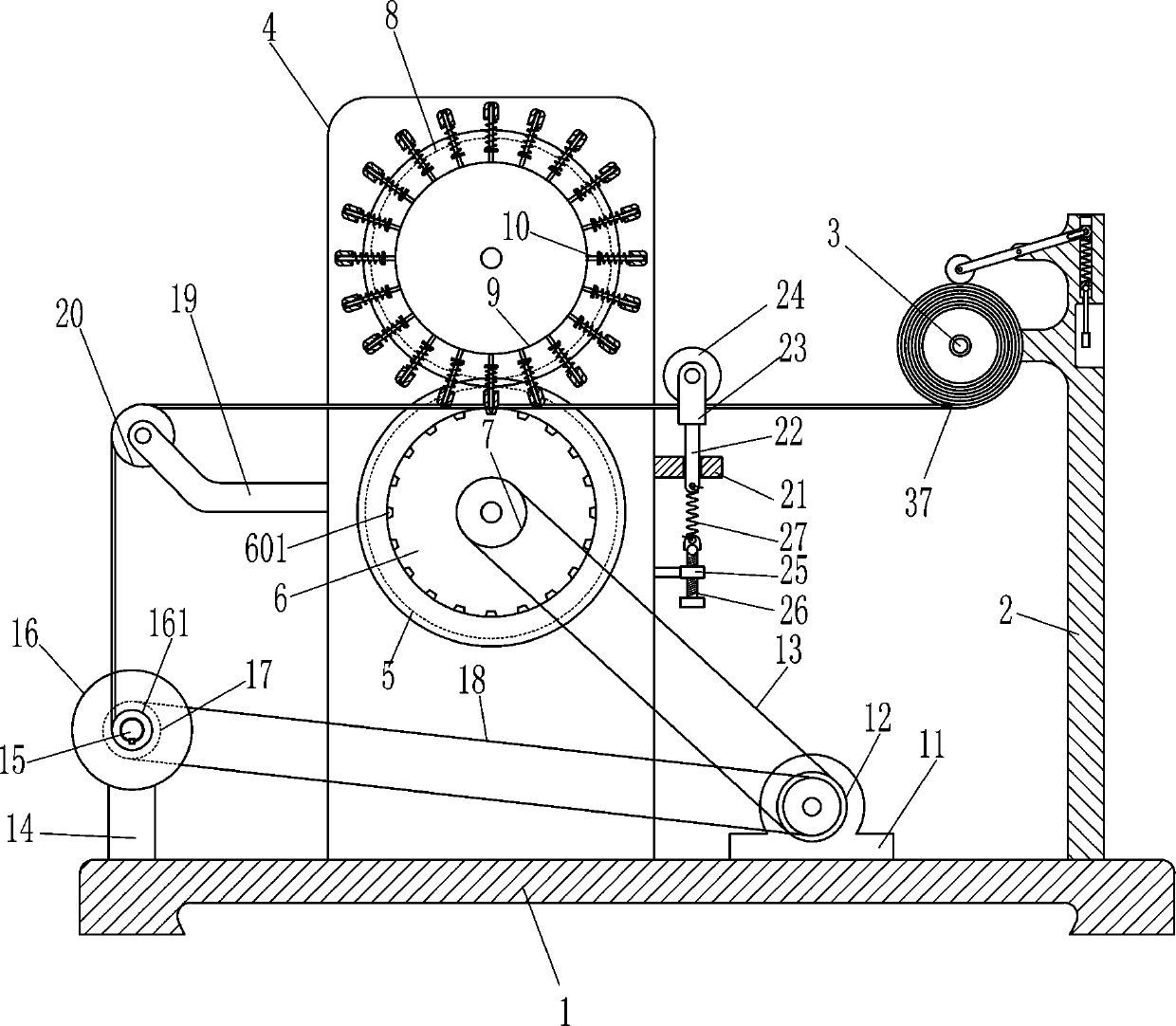

[0020] A sprinkler belt puncher such as Figure 1-4 As shown, it includes a base 1, a first frame 2, a first rotating rod 3, a mounting plate 4, a first gear 5, a first disc 6, a first pulley 7, a second gear 8, a second circle Disc 9, needle bar 10, motor 11, double groove pulley 12, first belt 13, second frame 14, second rotating rod 15, rotating disk 16, reel 161, second pulley 17, second belt 18. Arc-shaped struts 19 and first rollers 20, the top of the base 1 is provided with the second frame 14, the mounting plate 4, the motor 11 and the first frame 2 in sequence from left to right, and the left side of the first frame 2 The upper rotating type is provided with a first rotating rod 3, the first rotating rod 3 is wound with a water belt 37, and the front side rotating type of the mounting plate 4 is provided with a first gear 5 and a second gear 8, and the first gear 5 is located on the second gear 8, the first gear 5 meshes with the second gear 8, the first disc 6 is pr...

Embodiment 2

[0022] A sprinkler belt puncher such as Figure 1-4 As shown, it includes a base 1, a first frame 2, a first rotating rod 3, a mounting plate 4, a first gear 5, a first disc 6, a first pulley 7, a second gear 8, a second circle Disc 9, needle bar 10, motor 11, double groove pulley 12, first belt 13, second frame 14, second rotating rod 15, rotating disk 16, reel 161, second pulley 17, second belt 18. Arc-shaped struts 19 and first rollers 20, the top of the base 1 is provided with the second frame 14, the mounting plate 4, the motor 11 and the first frame 2 in sequence from left to right, and the left side of the first frame 2 The upper rotating type is provided with a first rotating rod 3, the first rotating rod 3 is wound with a water belt 37, and the front side rotating type of the mounting plate 4 is provided with a first gear 5 and a second gear 8, and the first gear 5 is located on the second gear 8, the first gear 5 meshes with the second gear 8, the first disc 6 is pr...

Embodiment 3

[0025] A sprinkler belt puncher such as Figure 1-4 As shown, it includes a base 1, a first frame 2, a first rotating rod 3, a mounting plate 4, a first gear 5, a first disc 6, a first pulley 7, a second gear 8, a second circle Disc 9, needle bar 10, motor 11, double groove pulley 12, first belt 13, second frame 14, second rotating rod 15, rotating disk 16, reel 161, second pulley 17, second belt 18. Arc-shaped struts 19 and first rollers 20, the top of the base 1 is provided with the second frame 14, the mounting plate 4, the motor 11 and the first frame 2 in sequence from left to right, and the left side of the first frame 2 The upper rotating type is provided with a first rotating rod 3, the first rotating rod 3 is wound with a water belt 37, and the front side rotating type of the mounting plate 4 is provided with a first gear 5 and a second gear 8, and the first gear 5 is located on the second gear 8, the first gear 5 meshes with the second gear 8, the first disc 6 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com