Novel practical anchor rod pile

An anchor pile, a practical technology, applied in sheet pile walls, protection devices, buildings, etc., can solve the problems of deformation anchor piles, insufficient self-weight, limited self-weight, etc., and achieve increased stability and great practical value. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

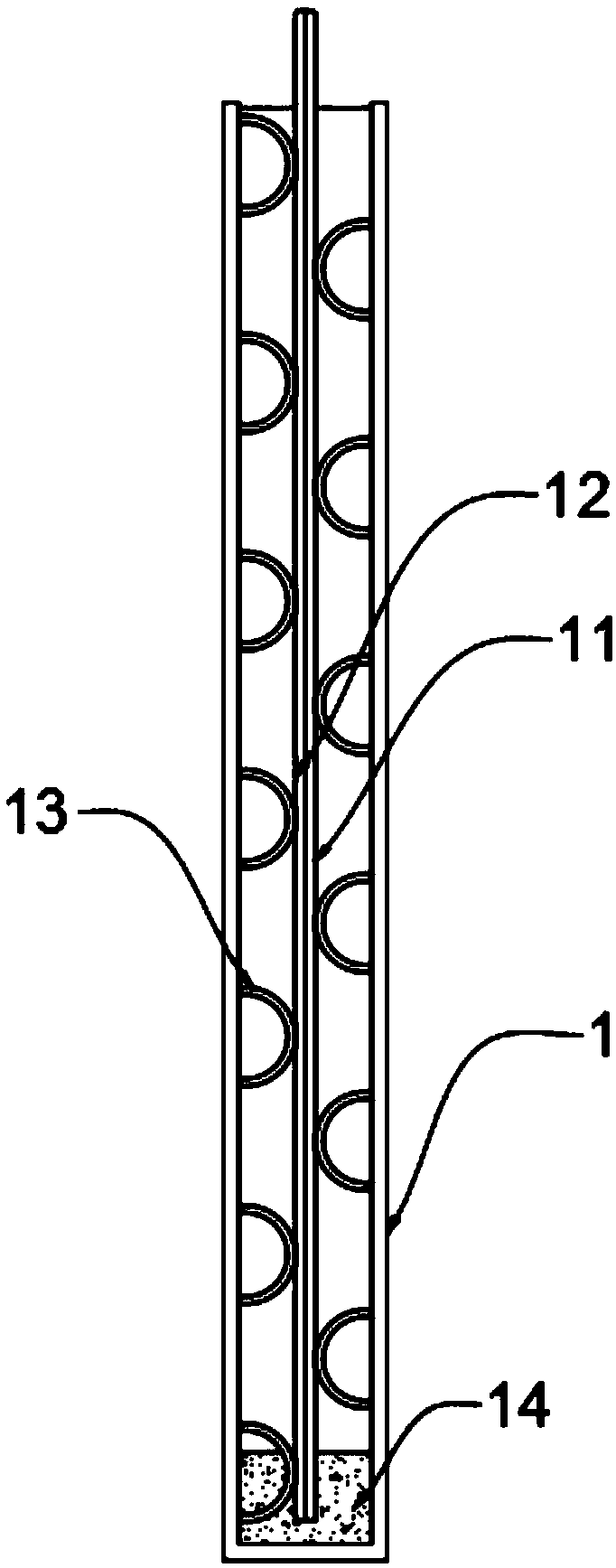

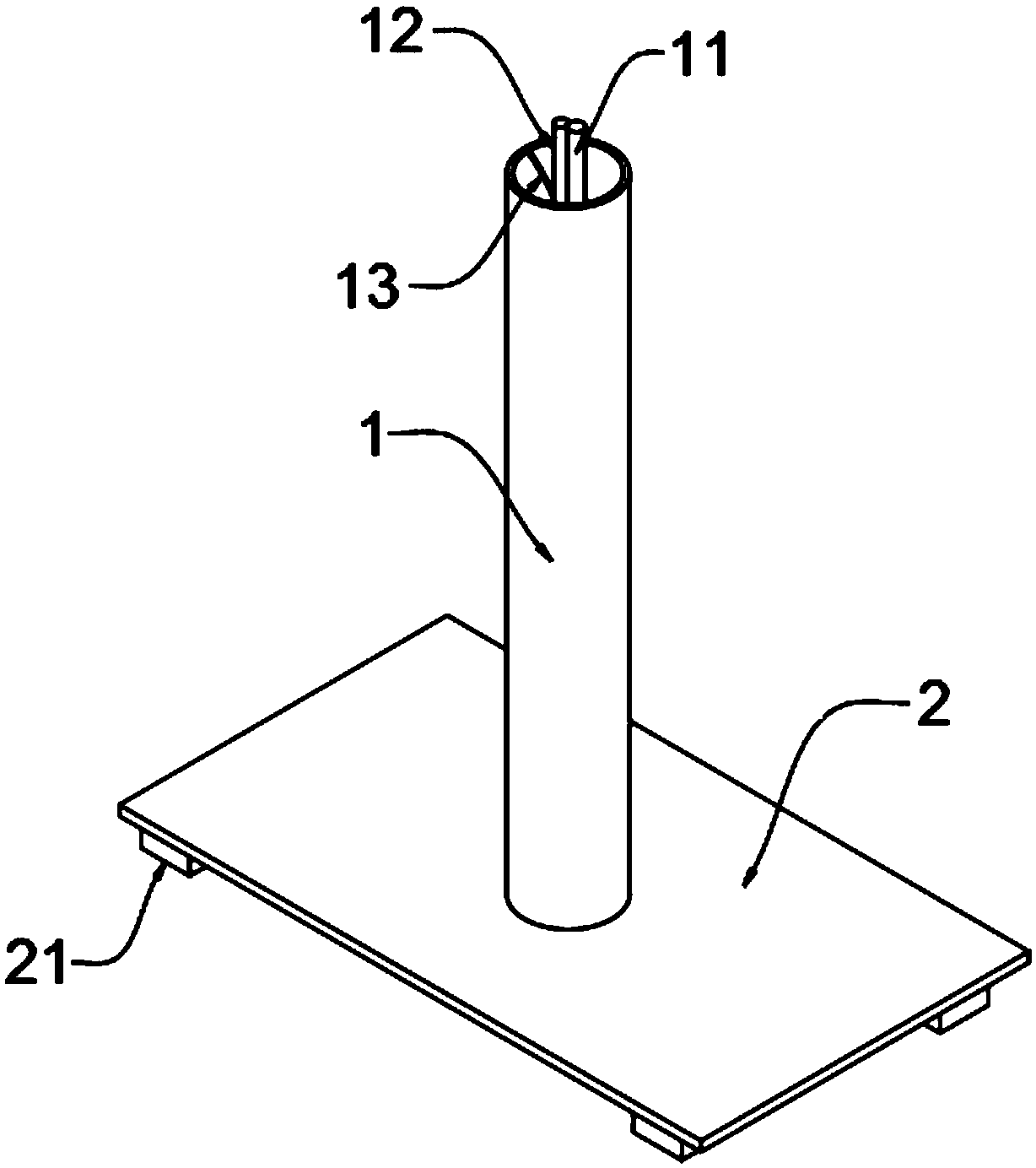

[0029] A new practical anchor pile, such as figure 1 and figure 2 As shown, the anchor pile body 1 is included, and the inside of the anchor pile body 1 is vertically provided with a first steel bar 11, and one side of the first steel bar 11 is provided with a water pipe 12, and the top of the first steel bar 11 and the water pipe 12 Both pass through the top opening of the anchor pile body 1, the anchor pile body 1 is a hollow tubular structure with an opening at the top, and the inner walls on both sides of the anchor pile body 1 are provided with a number of second reinforcement bars 13, the second reinforcement bars 13 It is a semi-circular arc structure, the upper and lower ends of the second steel bar 13 are tightly welded with the inner wall of the anchor pile body 1 respectively, the inner bottom surface of the anchor pile body 1 is provided with a grouting filling area 14, and the bottom of the anchor pile body 1 A bottom plate 2 is provided, and the bottom plate 2 ...

Embodiment 2

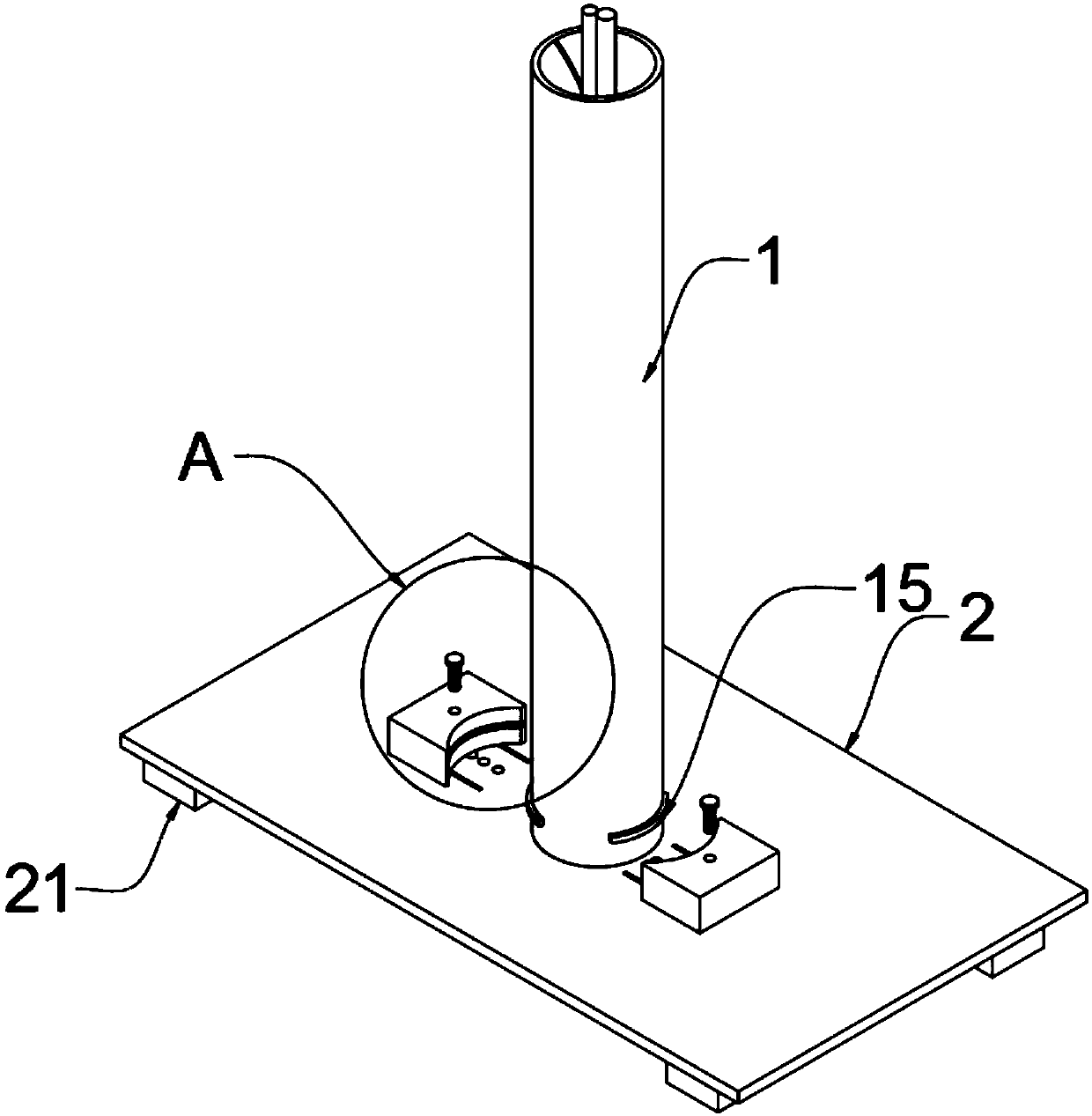

[0036] In specific use, the bottom of the anchor pile body 1 is easily subject to the buoyancy of groundwater when it is fixed and moves upward in the morning. Therefore, we make improvements to the anchor pile body 1 on the basis of Embodiment 1, as image 3 and Figure 4 As shown, the outer walls on both sides of the bottom of the anchor pile body 1 are symmetrically and tightly welded with clamping strips 15, and the outside of the clamping strips 15 is provided with a movable block 3, and the side of the movable block 3 close to the anchor pile body 1 is provided with a concave Groove 31 , the inside of the groove 31 is provided with a clamping groove 311 , and the clamping groove 311 is engaged with the clamping bar 15 by clamping.

[0037] Further, the top of the bottom plate 2 is provided with two chute 22 near the movable block 3, and the bottom of the movable block 3 is provided with a slider 34 near the chute 22, and the slider 34 is slidably connected with the chute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com