Pneumatic suction head for baked biscuits

A technology of biscuits and suction cups, applied in baking, food ovens, food science, etc., can solve problems such as inability to filter, blockage of the start-up system, etc., and achieve the effects of preventing system blockage, increasing the suction area, and smoothing the suction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

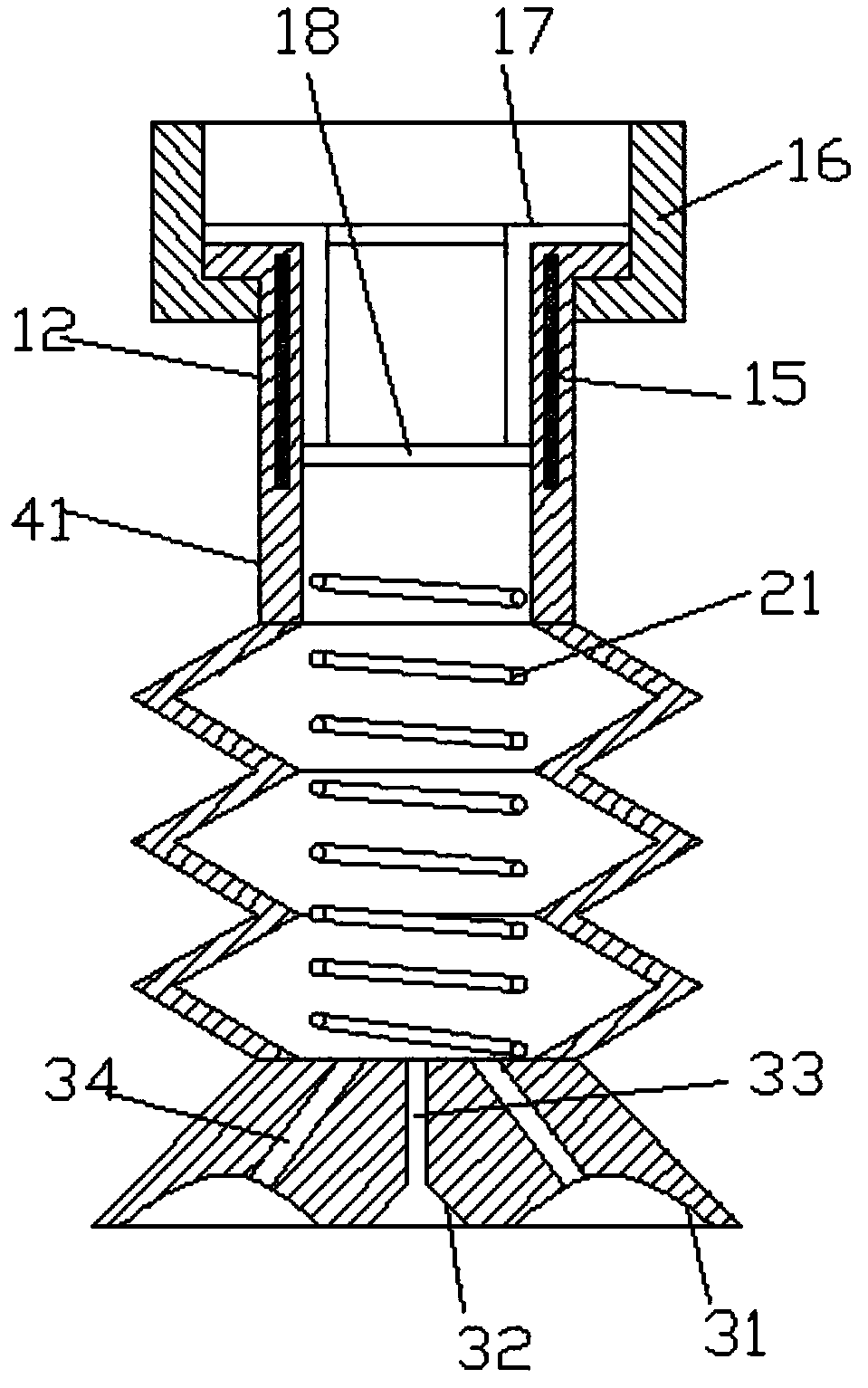

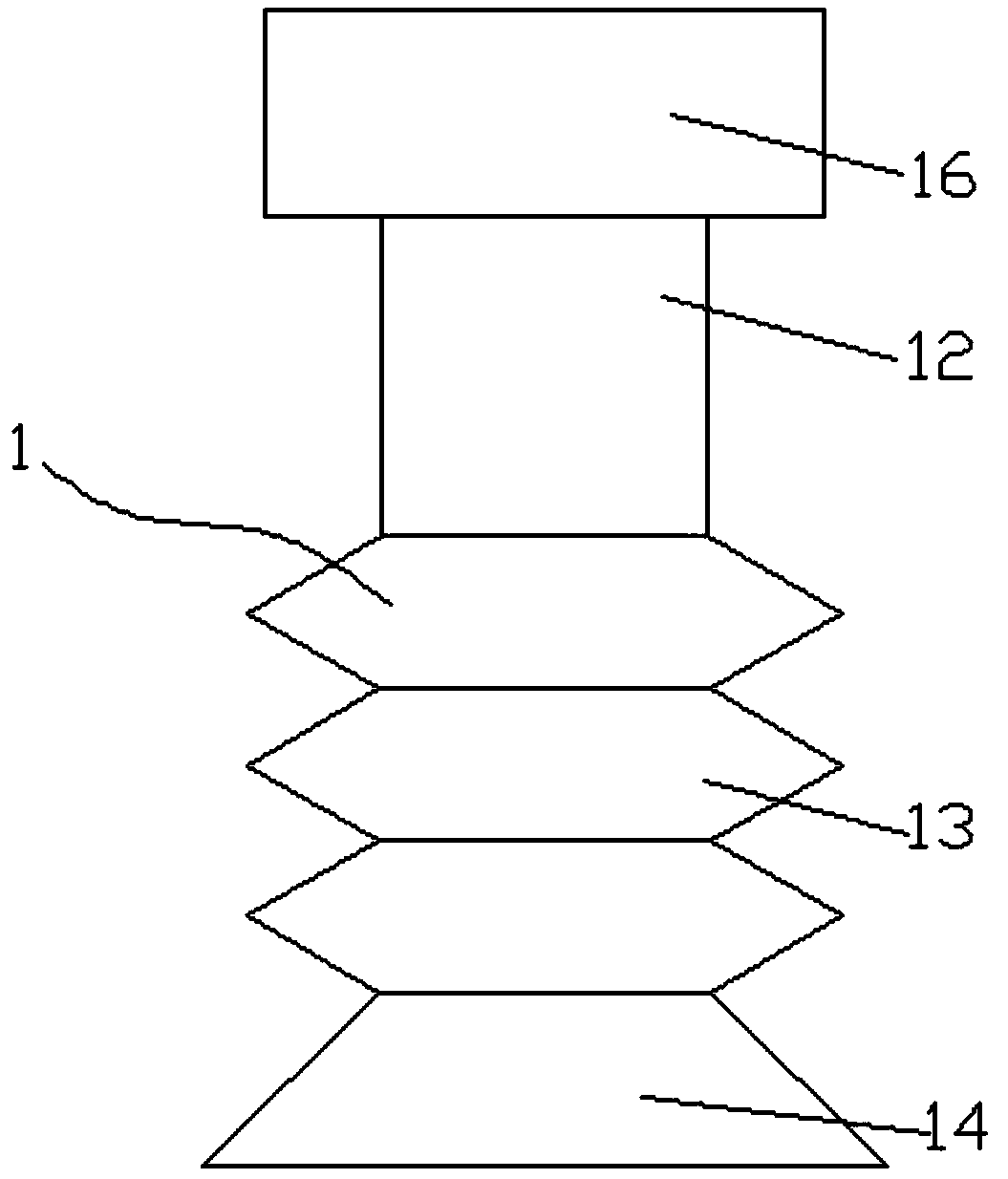

[0018] combine figure 1 , figure 2 As shown; a pneumatic suction head for baking biscuits, including a suction head body 1, the suction head body 1 includes a tailstock 12, a buffer section 13, and a suction head section 14, and an annular support plate 15 is embedded inside the tailstock 12, The outer ring of the tailstock 12 is installed with a fixed nut 16, and the end of the tailstock 12 is installed with a support frame 17. The end of the support frame 17 is located inside the sleeve where the tailstock 12 is installed, and a filter screen is installed at the end of the support frame 17. plate 18. When the suction head sucks the biscuit, the filter plate at the end of the support frame is used to filter the inhaled gas to prevent the residue on the surface of the biscuit from entering the interior of the pneumatic system and prevent the system from being blocked

[0019] A steel mesh structure is embedded inside the buffer section 13 , and a buffer spring 21 is install...

Embodiment 2

[0023] combine figure 1 , figure 2 As shown; a pneumatic suction head for baking biscuits, including a suction head body 1, the suction head body 1 includes a tailstock 12, a buffer section 13, and a suction head section 14, and an annular support plate 15 is embedded inside the tailstock 12, The outer ring of the tailstock 12 is installed with a fixed nut 16, and the end of the tailstock 12 is installed with a support frame 17. The end of the support frame 17 is located inside the sleeve where the tailstock 12 is installed, and a filter screen is installed at the end of the support frame 17. plate 18. When the suction head sucks the biscuit, the filter plate at the end of the support frame is used to filter the inhaled gas to prevent the residue on the surface of the biscuit from entering the interior of the pneumatic system and prevent the system from being blocked

[0024] A steel mesh structure is embedded inside the buffer section 13 , and a buffer spring 21 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com