A construction method of a flexible anchor rod

A construction method and bolt technology, which are applied in the installation of bolts, earthwork drilling, mining equipment, etc., can solve problems such as the inability to reinforce the anchor cable anchorage area, the inability to meet the geological environment, and the inability to apply pre-tightening force, etc., to achieve improved anchorage The speed of pole support, the realization of quality standardization, and the effect of efficient installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

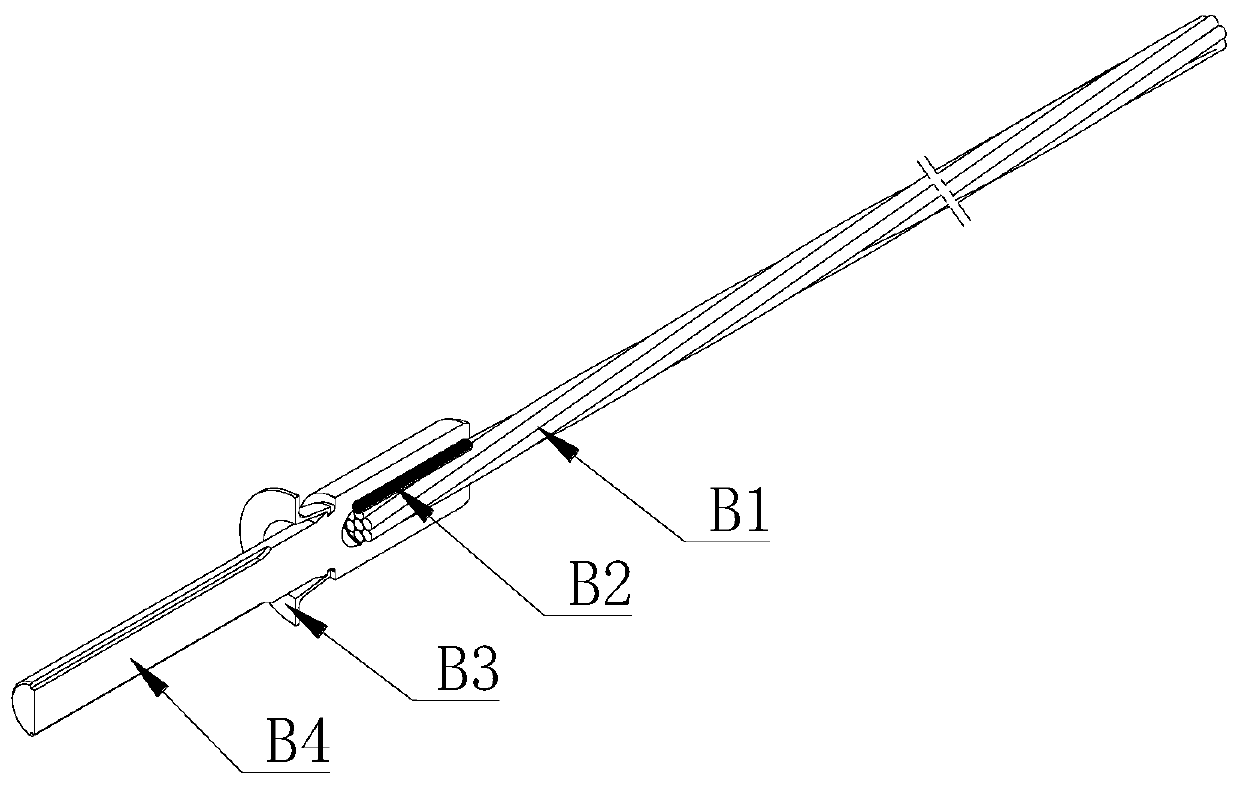

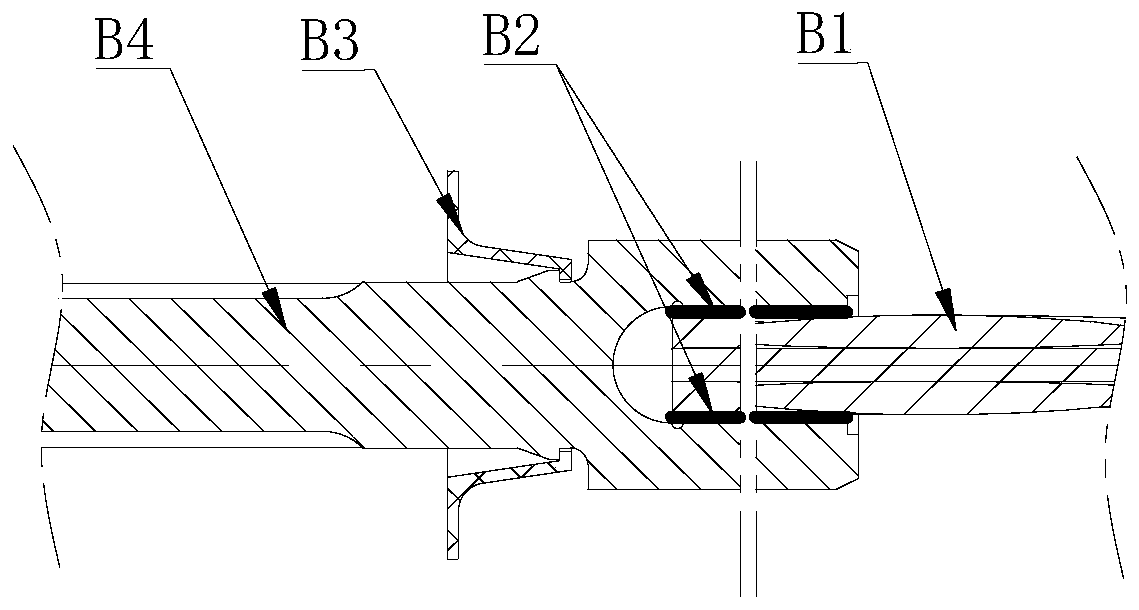

[0034] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a flexible anchor rod of the present invention includes a flexible anchor rod body B, a tray C, a fixed torque nut D, an anti-friction washer E and an anti-twist self-aligning ball head F, wherein the tray C is arranged on the flexible anchor rod body At the tail of B, the fixed torque nut D fixes the pallet C, and an anti-friction washer E and an anti-rotation self-aligning ball head F are arranged between the pallet C and the fixed torque nut D;

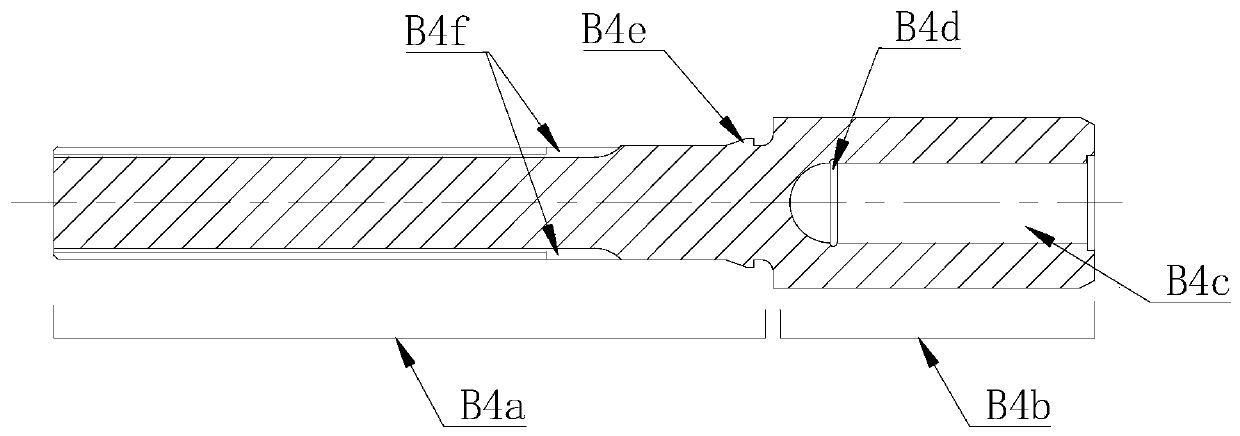

[0035] The flexible anchor body B includes a steel strand B1, and the tail end of the steel strand B1 is arranged in a connecting sleeve B4, and the connecting sleeve B4 includes a tail end B4a and a head end B4b, and a connection between the tail end B4a and the head end B4b The transition section is provided with a ring-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com