Factory-like procambarus clarkii breeding method

A Procambarus clarkii, industrialized technology, applied in the field of breeding, can solve the problems of uneven specifications and large individual differences, and achieve the effect of neat specifications, avoiding individual differences, and ensuring synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

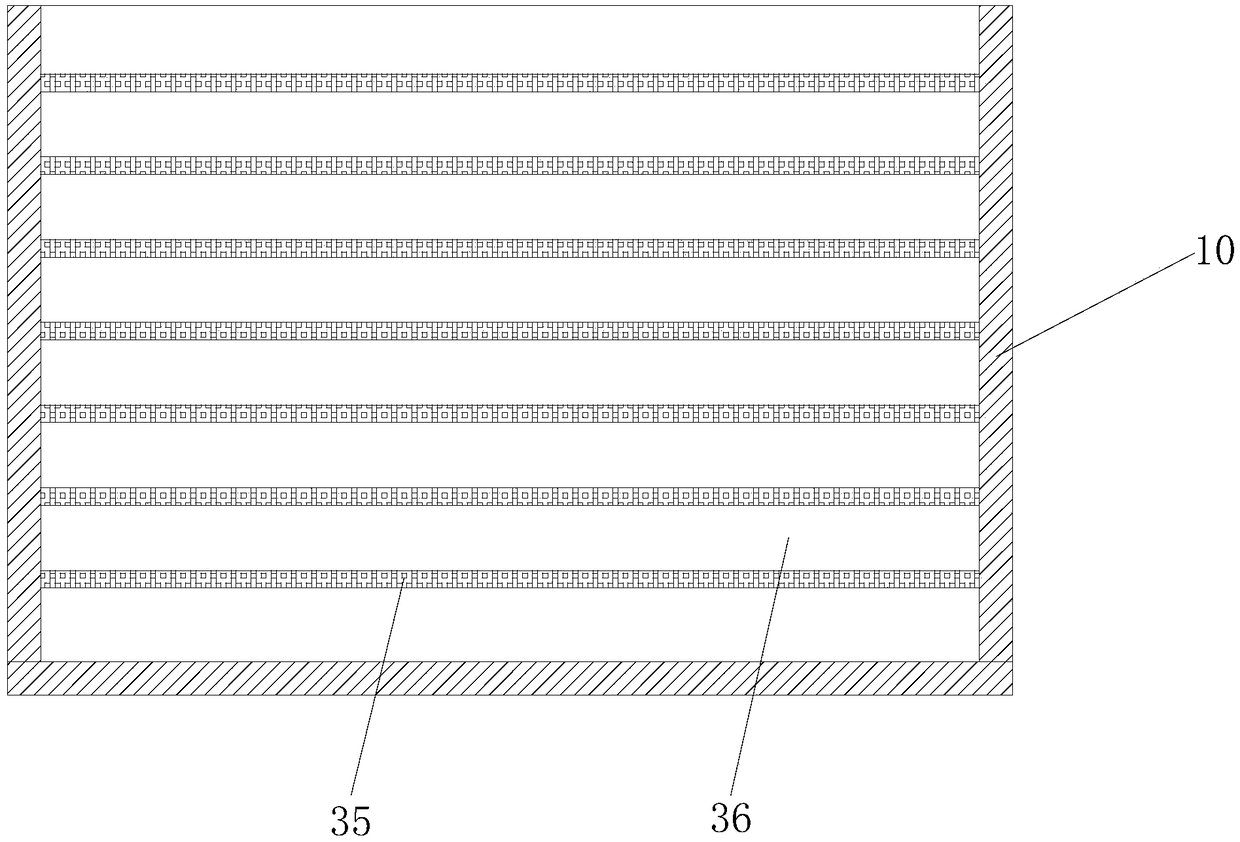

[0067] see figure 1 , the present embodiment provides an industrial Procambarus clarkii breeding method, which is applied in a culture system. The breeding system includes a breeding area, a sewage collection area and a mixing area. The mixing area is used to transport the liquid mixed with biofloc to one end of the breeding area. The sewage collection area is used to collect the sewage discharged from the breeding area and purify it and send it to the mixing area. The breeding area, the sewage collecting area and the mixing area are three areas separated in a breeding pond 10 . A plurality of isolation nets 36 arranged in parallel and at equal intervals are set in the breeding area, and the isolation nets 36 divide the breeding area into a plurality of breeding spaces 37 .

[0068] Wherein, the industrialized Procambarus clarkii breeding method of the present embodiment comprises:

[0069] Step 1, according to the male-to-female ratio of 1:1, put the Procambarus clarkii par...

Embodiment 2

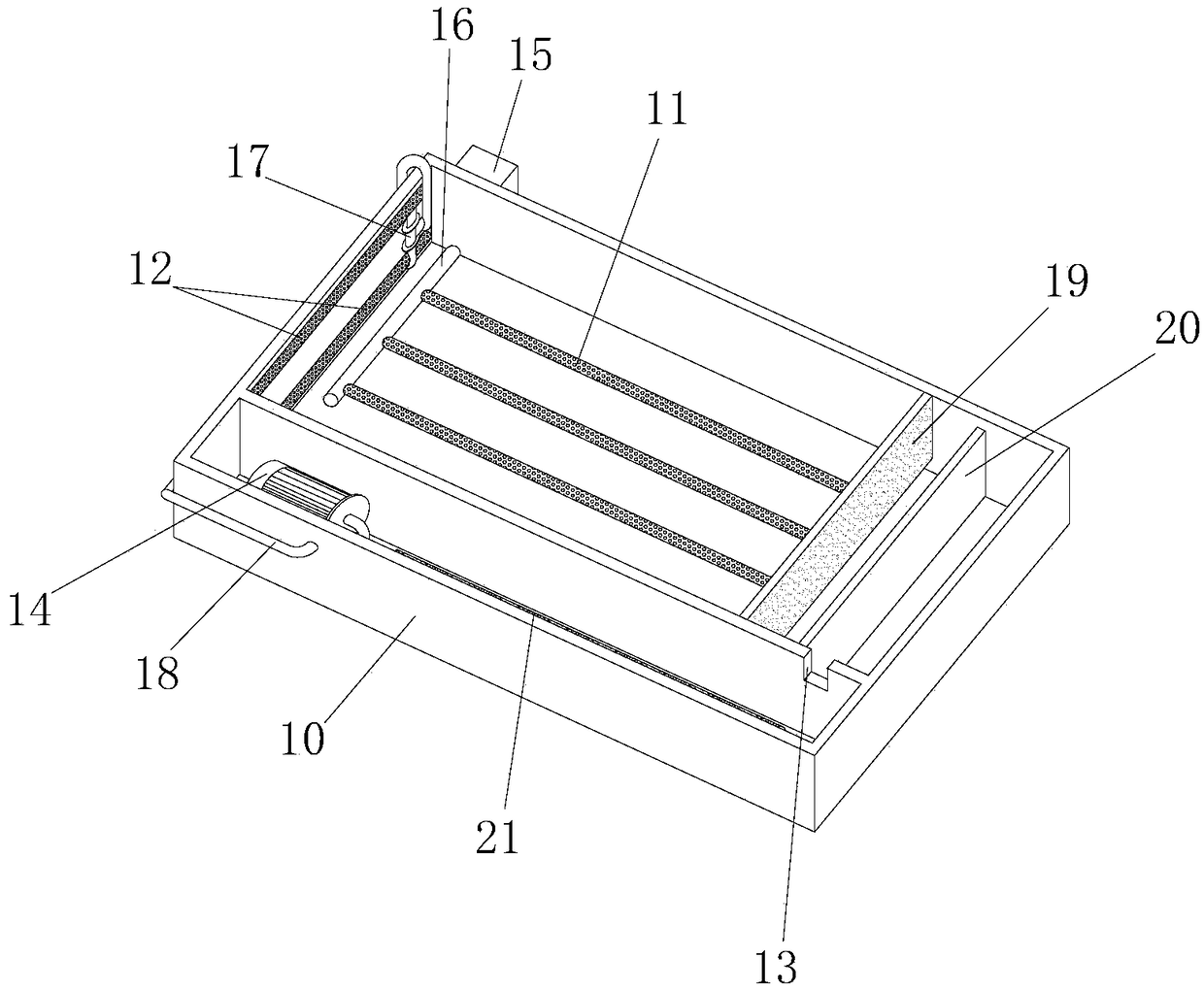

[0081] see figure 2 , the cultivation system applied in the industrialized Procambarus clarkii breeding method of the present embodiment is similar to the cultivation system in embodiment 1, the difference is:

[0082] A baffle is arranged in the culture pond 10, and the baffle is arranged along the length direction of the culture pond 10, and divides the culture pond 10 into two independent storage tanks. Among the two storage tanks, the storage tank with a smaller volume is a mixing area, and the storage tank with a larger volume is divided into a breeding area and a sewage collection area by a one-way overflow structure.

[0083] A plurality of aeration pipes 11 are arranged at the bottom of the breeding area, and at least one water inlet pipe 12 is arranged at the water inlet end of the breeding area. Specifically, the number of oxygen increasing pipes 11 may be three, and the three oxygen increasing pipes 11 are arranged in parallel and at equal intervals. The quantity...

Embodiment 3

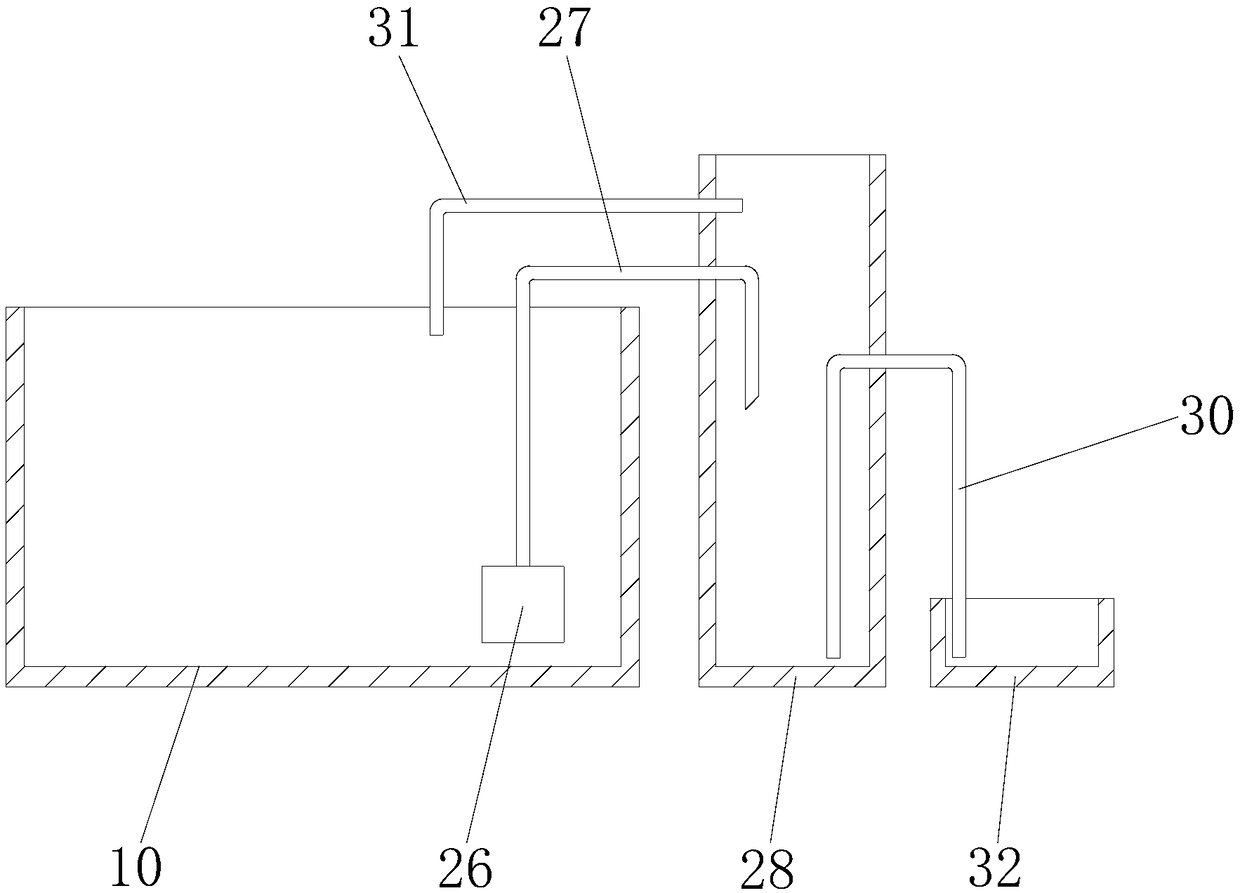

[0129] see Figure 4 The biofloc separation device used in the industrialized Procambarus clarkii culture method of this embodiment is based on the electronic valve 33 in Embodiment 1, and the electronic valve 33 is used to open or close the second delivery pipe 30 .

[0130] Moreover, the settling cavity of the settling separator 28 is a sealed cavity, and is sealed by a sealing cover 29 . The cross-sectional area of the other end of the first feed pipe 27 is S, and the cross-sectional area of one end of the second feed pipe 30 is S 1 , the cross-sectional area of one end of the return pipe 31 is S 2 ; where S=S 1 +S 2 , to ensure the balance of the ingress and egress of the aquaculture water body in the sedimentation separator 28. In this way, when the aquaculture water body in the sedimentation separator 28 is so large that the sealed cavity is filled, the aquaculture wastewater entering from the first feeding pipe 27 will press the larger biological flocs to be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com