Rapid analysis method of pulverizing and cutting degree of nitrocellulose

A nitrocellulose, rapid analysis technology, applied in the direction of analysis materials, measuring devices, instruments, etc., can solve the problems of large, burning in case of fire, large human operation error, large reading error, etc., to eliminate accidental errors and reduce power consumption. consumption, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

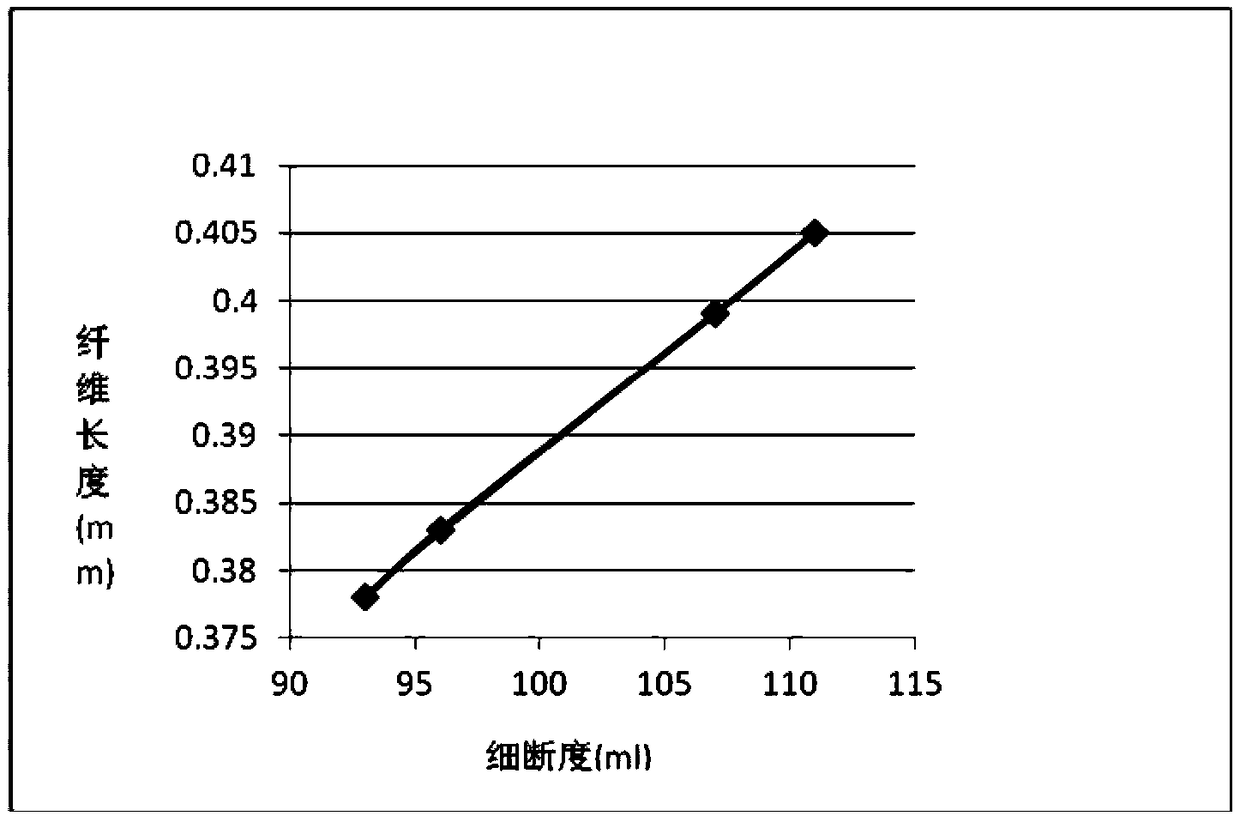

[0032] Select 4 groups of Class A nitrocellulose with different fineness for fiber test, use fiber quality analyzer to count the fiber length Lc(n) / mm value, and use existing standard method to obtain fineness, as shown in Table 1, figure 1 Shown:

[0033] Table 1

[0034]

[0035] Carry out linear fitting, obtain the relational formula of the cellulose fiber length and the degree of fineness to be fiber length=a* degree of fineness+b, wherein a is 0.0015, and b is 0.2399, by figure 1 It can be seen that the fiber length obtained from the analysis has a very good correlation with the degree of fineness, and the correlation coefficient R can reach 0.9997. Therefore, when analyzing the fineness of Class A nitrocellulose, it is only necessary to analyze and count the fiber length, and then enter the relational formula: fiber length = 0.0015 × fineness + 0.2399, to obtain the fineness of Class A nitrocellulose.

Embodiment 2

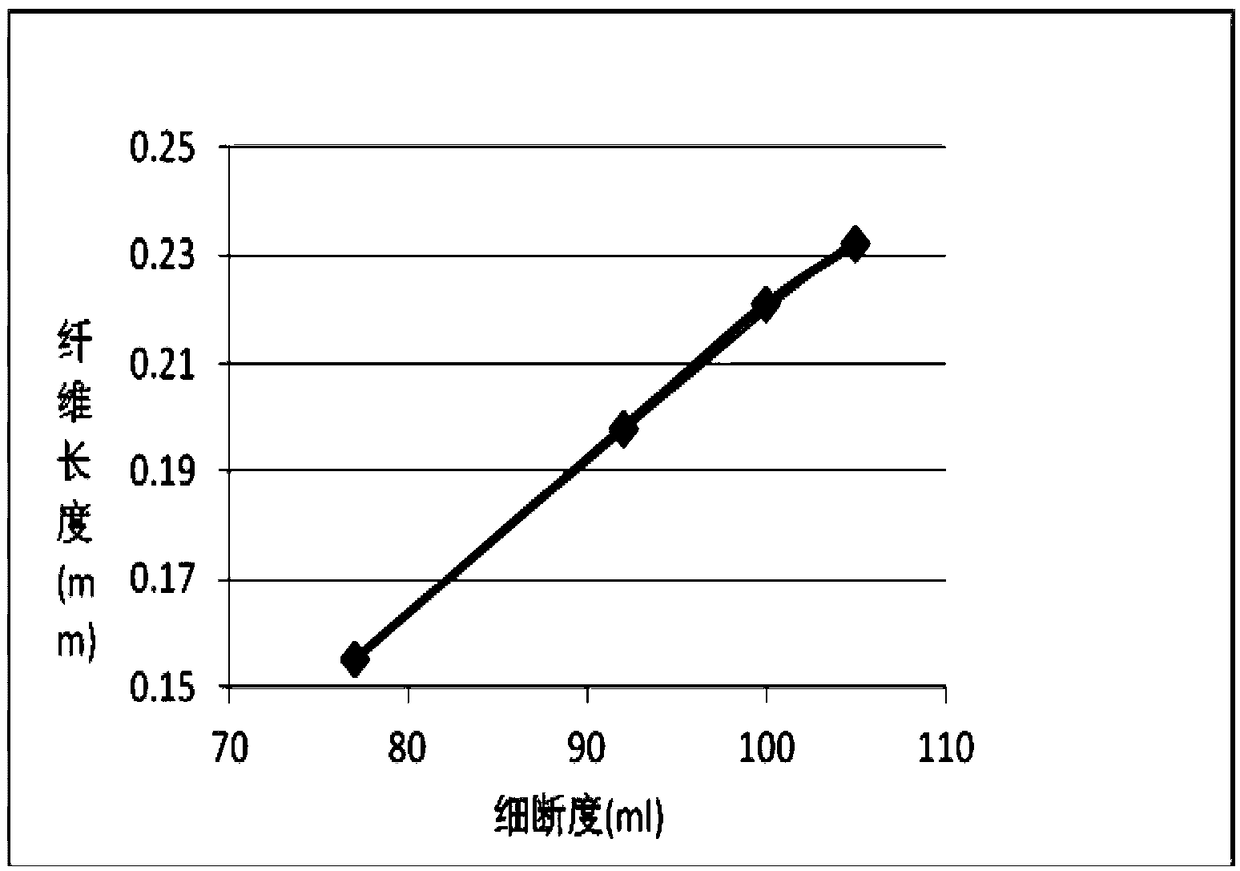

[0037] Select 4 groups of B-type nitrocellulose with different fineness for fiber test, use fiber quality analyzer to count the fiber length Lc(n) / mm value, and use existing standard method to obtain fineness, as shown in Table 2, figure 2 Shown:

[0038] Table 2

[0039]

[0040] Carry out linear fitting, obtain the relational formula of the cellulose fiber length and the degree of fineness to be fiber length=a* degree of fineness+b, wherein a is 0.0028, b is-0.0588, by figure 2 It can be seen that the correlation between the fiber length and the degree of fineness obtained by the analysis is very good, and the correlation coefficient R can reach 0.9986. Therefore, when analyzing the fineness of Class B nitrocellulose, it is only necessary to analyze and count the fiber length, and then enter the relational formula: fiber length = 0.0028 × fineness - 0.0588, to obtain the fineness of Class B nitrocellulose.

Embodiment 3

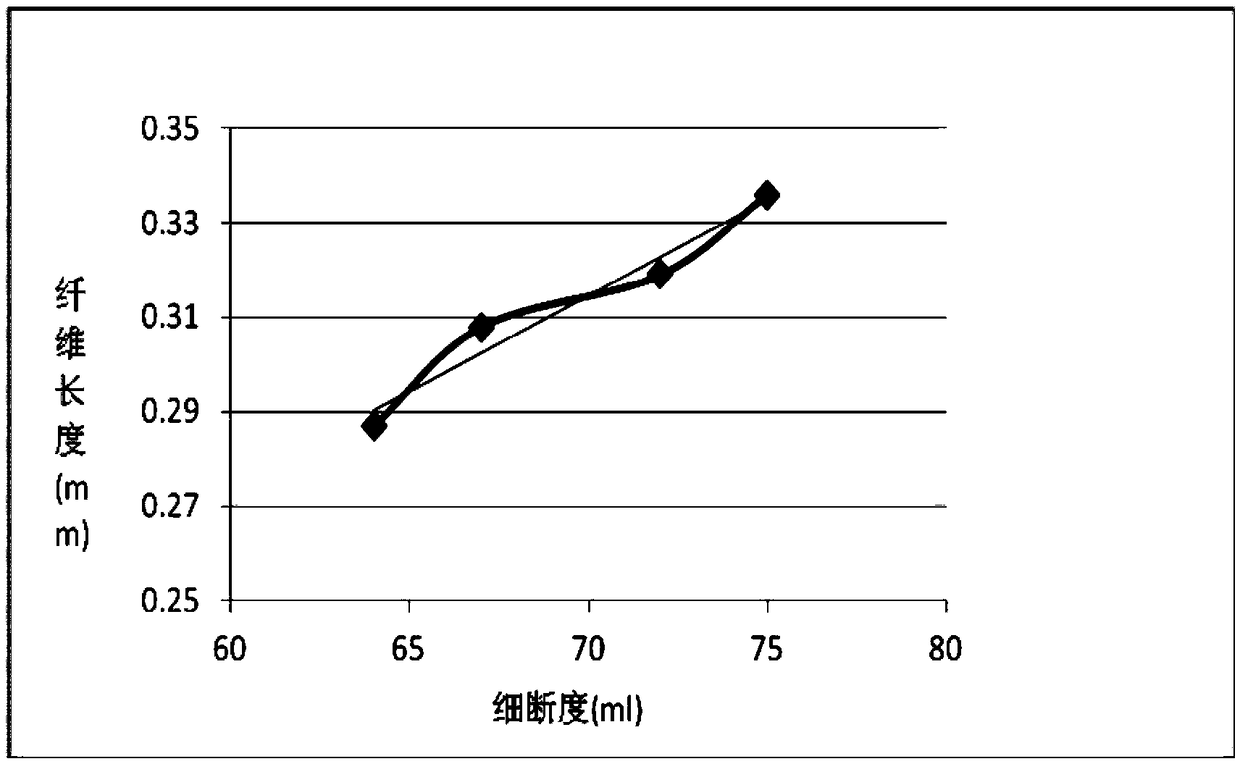

[0042] Select 4 groups of D-type nitrocellulose with different fineness for fiber test, use the fiber quality analyzer to count the fiber length Lc(n) / mm value, and use the existing standard method to obtain the fineness, as shown in Table 3, image 3 Shown:

[0043] table 3

[0044]

[0045] Carry out linear fitting, obtain the relational expression of chemical cellulose fiber length and fineness degree to be fiber length=a* fineness degree+b, wherein a is 0.0041, and b is 0.0297, by image 3 It can be seen that the correlation between the fiber length and the degree of fineness obtained by the analysis is very good, and the correlation coefficient R can reach 0.9552. Therefore, when analyzing the fineness of Class D nitrocellulose, it is only necessary to analyze and count the fiber length, and then enter the relational formula: fiber length = 0.0041 × fineness + 0.0297, to obtain the fineness of Class D nitrocellulose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com