Sphericity measuring device and method based on machine vision technology

A sphericity measurement and machine vision technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of easily damaged workpiece surface, large comprehensive error, limited by the measurement environment, etc., to achieve fast and flexible data processing and high precision. , The effect of strong anti-interference ability on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods. The steps involved in the present invention can all be realized according to the prior art unless otherwise specified.

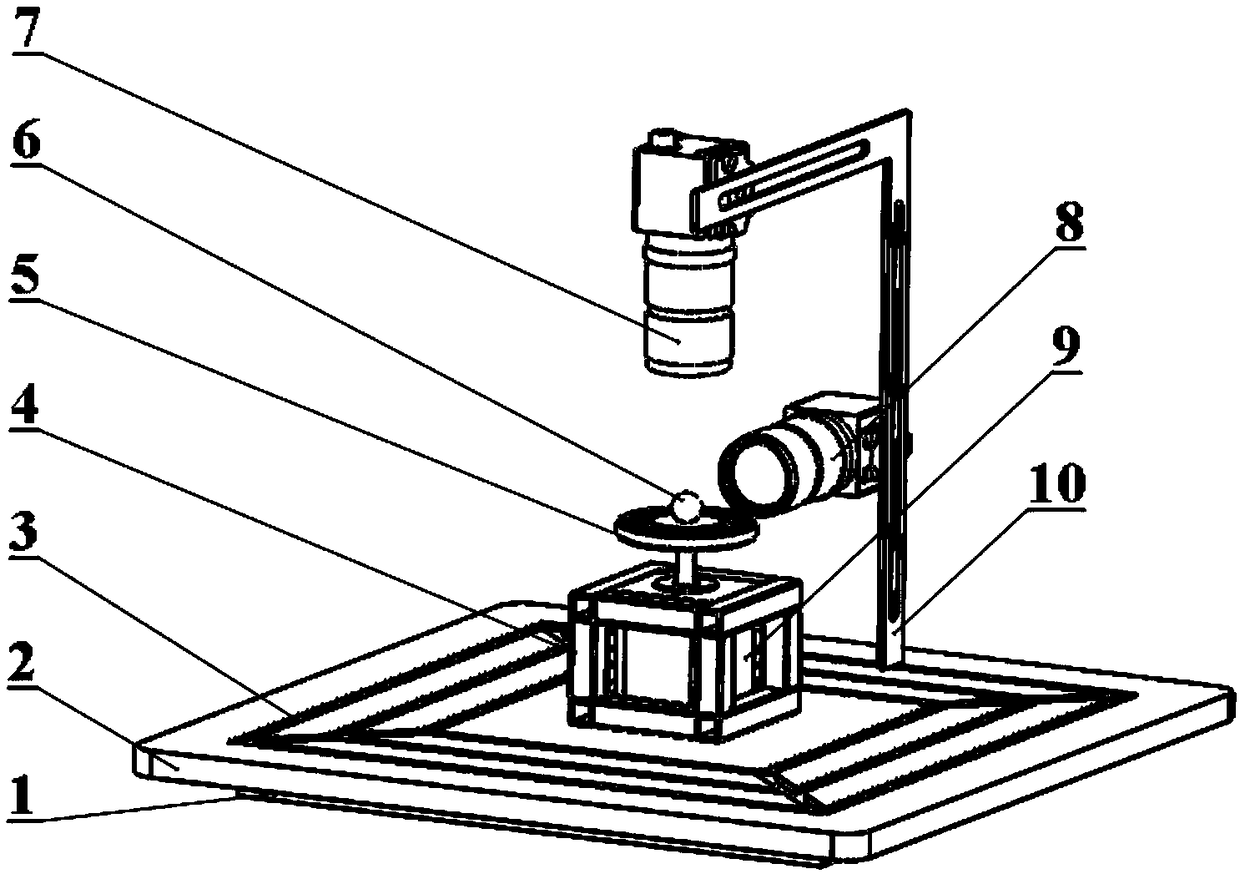

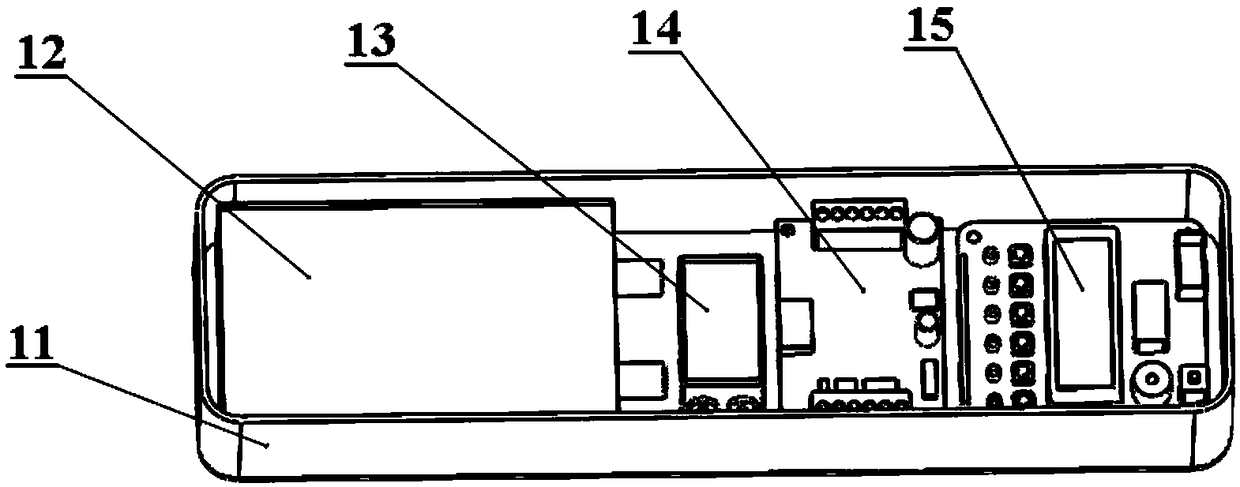

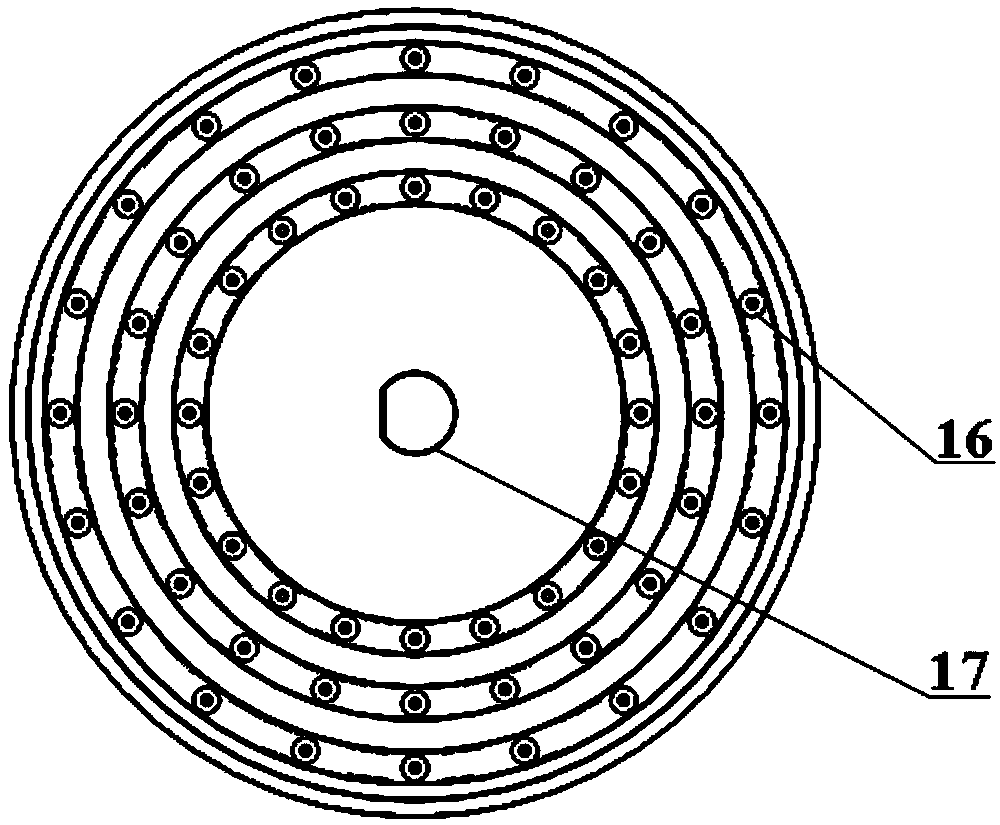

[0035] Such as Figure 1-Figure 6 As shown, a sphericity measurement device based on machine vision technology described in this embodiment includes a base, a storage table, a background box 18, a power module, a control mechanism and an image acquisition mechanism.

[0036] The base is composed of a support base 1, a base 2 and a track 3, the base 2 is a square thin plate, the support base 1 is a square, fixedly installed directly below the base 2, and the center of the support base is on the same line as the center of the base Above; the track 3 is fixedly installed directly above the base 2 according to the square structure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com