A three-way hydraulic four-link assembly platform

An assembly platform and four-link technology, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, difficult assembly, thick diameter, etc., and achieve reduced labor intensity, flexible and convenient operation, and Flexible and varied effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

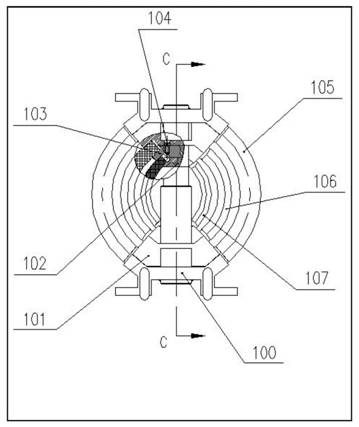

[0047] One embodiment: the liftable fine-leveling worktable includes a worktable, a sliding seat, and a guide plate; the worktable on the liftable fine-leveling workbench matches the sliding seat through a slope, and the dovetail of the sliding seat is aligned with the sliding seat. The dovetail groove structure of the guide plate is connected and guided by the dovetail groove of the guide plate, so that the sliding seat can slide in the horizontal direction; the movement of the sliding seat drives the adjustment of the tilting angle of the working table. The entire liftable micro-leveling workbench can realize vertical lifting movement and horizontal micro-leveling within a certain range, and has self-locking characteristics.

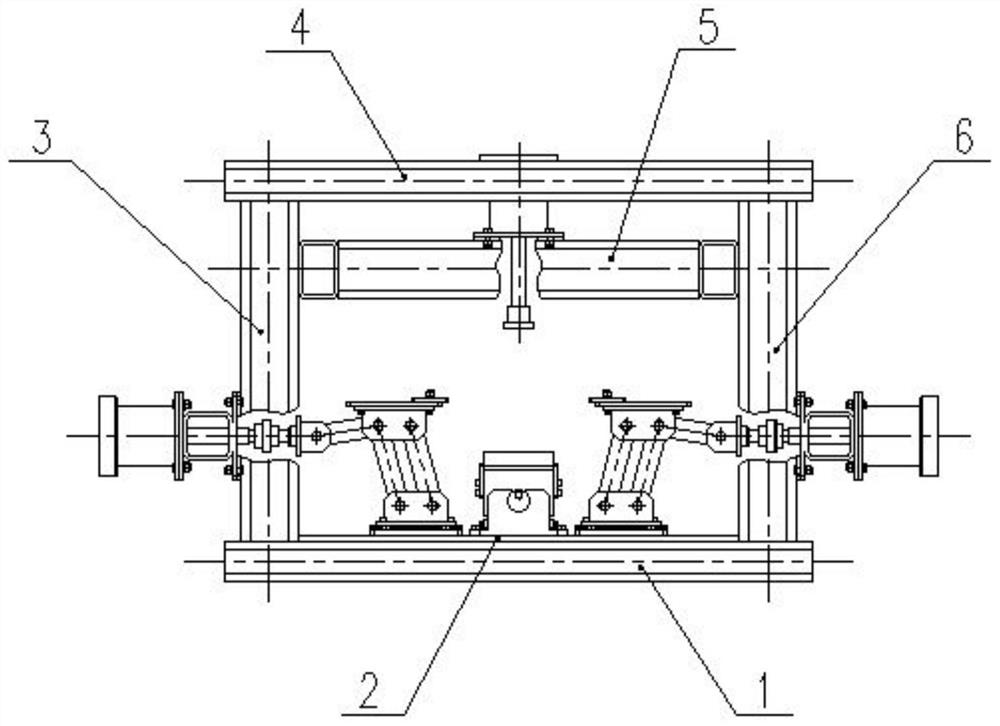

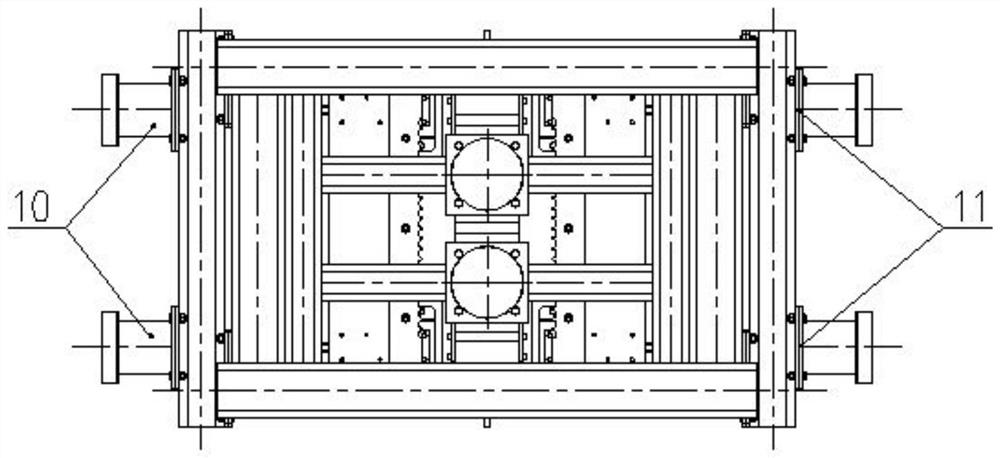

[0048] Further, the equipment body is welded by upper and lower ring beams, left and right columns, horizontal beams 5 and installation base plate 2 . The left and right columns include a left ear column 3 and a right ear column 6;

[0049] Weld the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com