Rotary tillage, ditch forming, front-position fertilizer applying, sowing and spraying combined operation machine

A technology of combined working machine and rotary tiller, which is used in fertilizer and seeding equipment, agricultural machinery and implements, excavation/covering of trenches, etc. , improve adaptability and reliability, simplify the structure of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

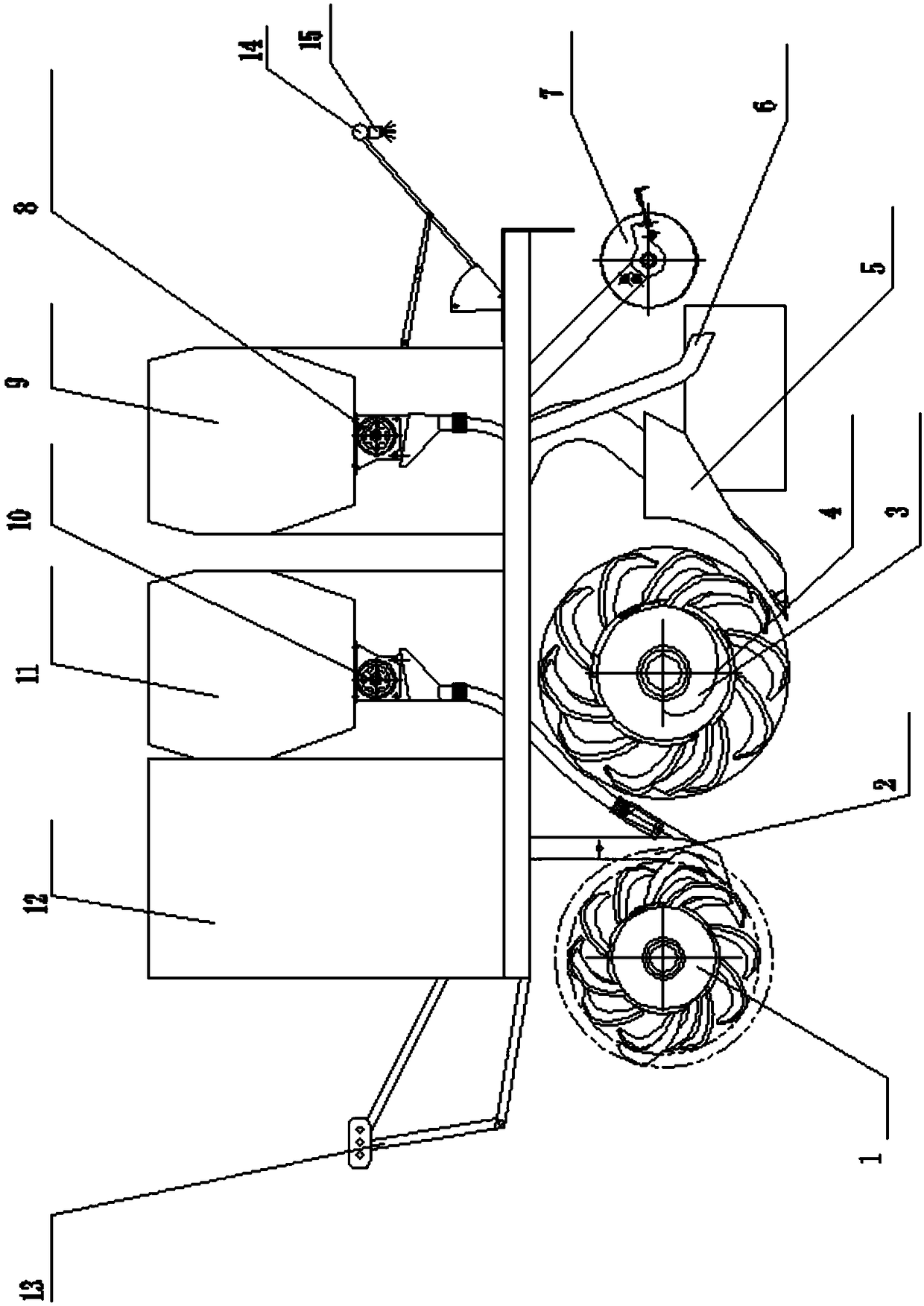

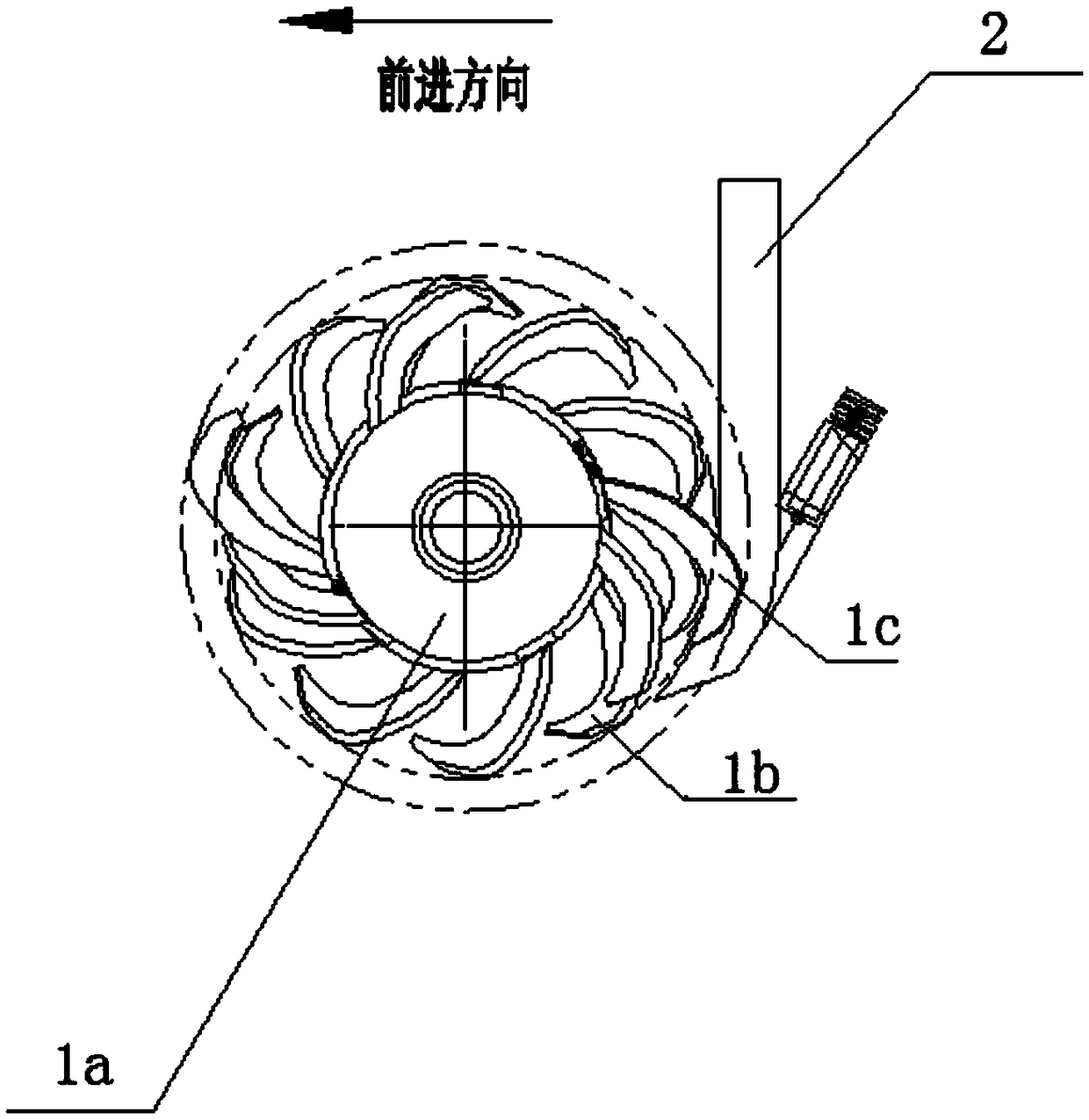

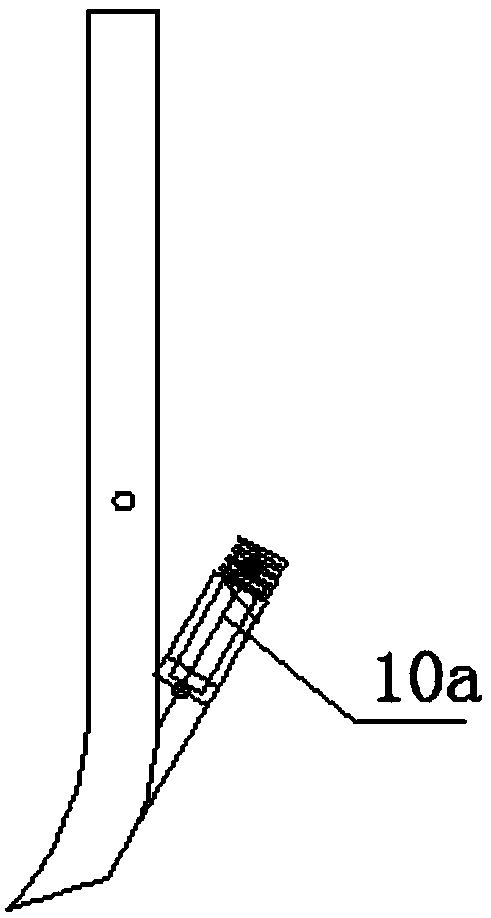

[0040] see Figure 1-Figure 7, a combined operation machine for rotary tillage, ditching, upright fertilization, sowing, and spraying, which is sequentially equipped with a rotary tiller 1, a fertilization ditch opener 2, a rotary cutting ditch opener 3, and a drainage ditch ditch. Pear 5, seeding ditch opener 6, pressing wheel 7; the rotary tiller 1 is arranged at the position close to the fertilization ditch opener 2, so that the end of the rotary tiller machete 1b of the rotary tiller 1 is close to the ditch opener The front of the lower part, but not in contact; on the rotating shaft of the rotary cultivator 1, several side clearing straight knives 1c are added, and the radius of rotation of the outermost end of the straight knives is greater than the outermost radius of rotation of the rotary scimitar, and the side clearing straight knives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com