Food material full-automatic extrusion dehydration device

A extrusion dehydration, fully automatic technology, applied in the direction of dehydration preservation of fruits/vegetables, etc., can solve the problems of low efficiency, and achieve the effect of high efficiency, convenient operation, and stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

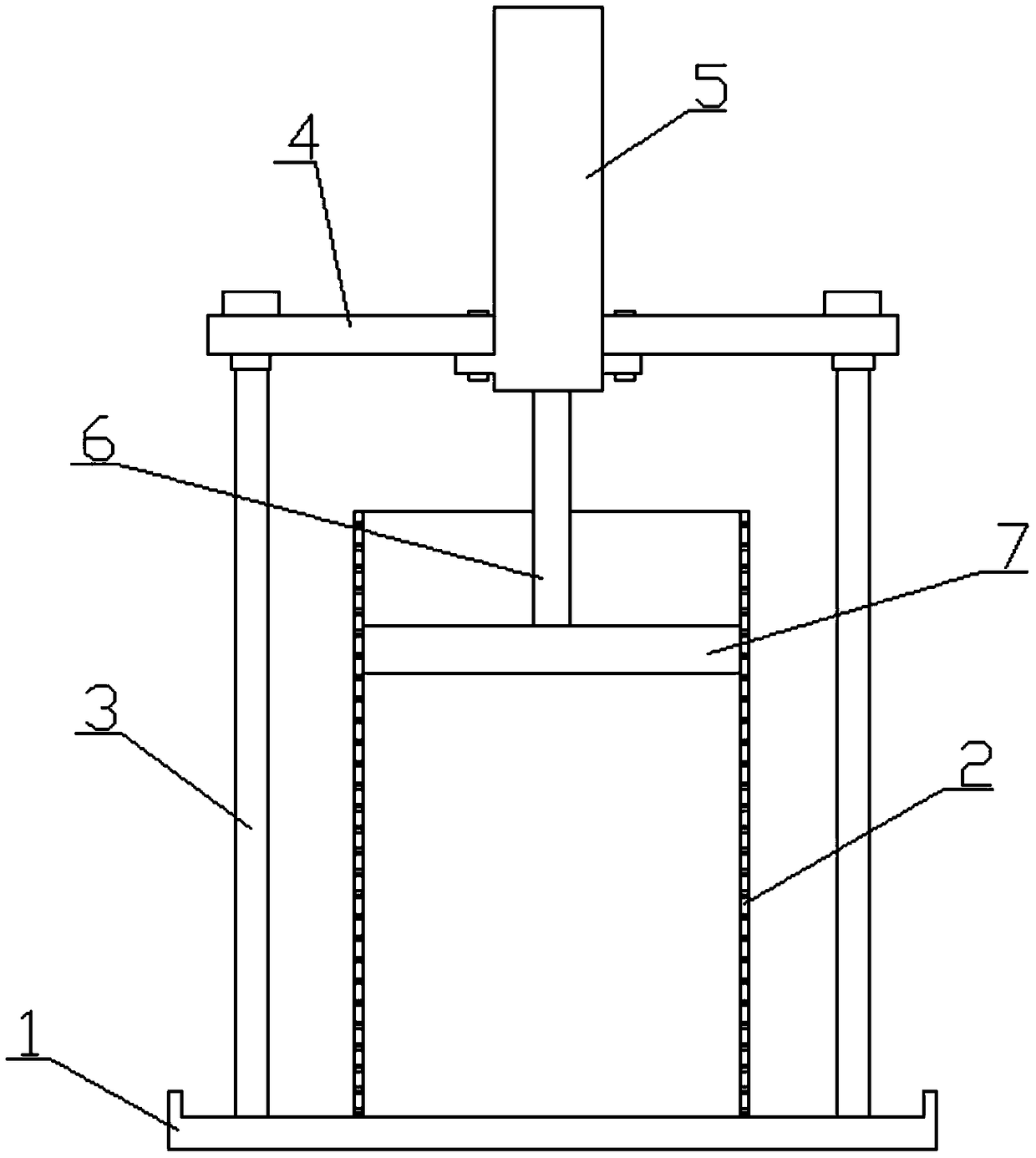

[0019] Such as figure 1 As shown, the automatic extrusion dehydration device for food materials includes a base 1, a dehydration barrel 2 extending upward is fixed on the upper middle of the base 1, and a number of through holes are arranged on the wall of the dehydration barrel 2. The circumferential direction of the dehydration barrel 2 on the base 1 is A support column 3 extending upwards is fixed, and the support column 3 supports a support plate 4. The middle part of the support plate 4 is vertically fixed with a hydraulic device 5. The piston 6 of the hydraulic device 5 extends into the dehydration bucket 2, and the hydraulic rod 5 A gland 7 is fixedly arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com