A fully automatic semiconductor wafer glue spraying mechanism and glue spraying equipment

A semi-conductive and fully automatic technology, applied in the direction of spraying device, can solve the problems of nozzle blockage, affecting the quality of spraying, unstable spraying situation, etc., to prevent nozzle blockage, improve spraying effect, and improve spraying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention more obvious and understandable, the detailed description is as follows in conjunction with the accompanying drawings.

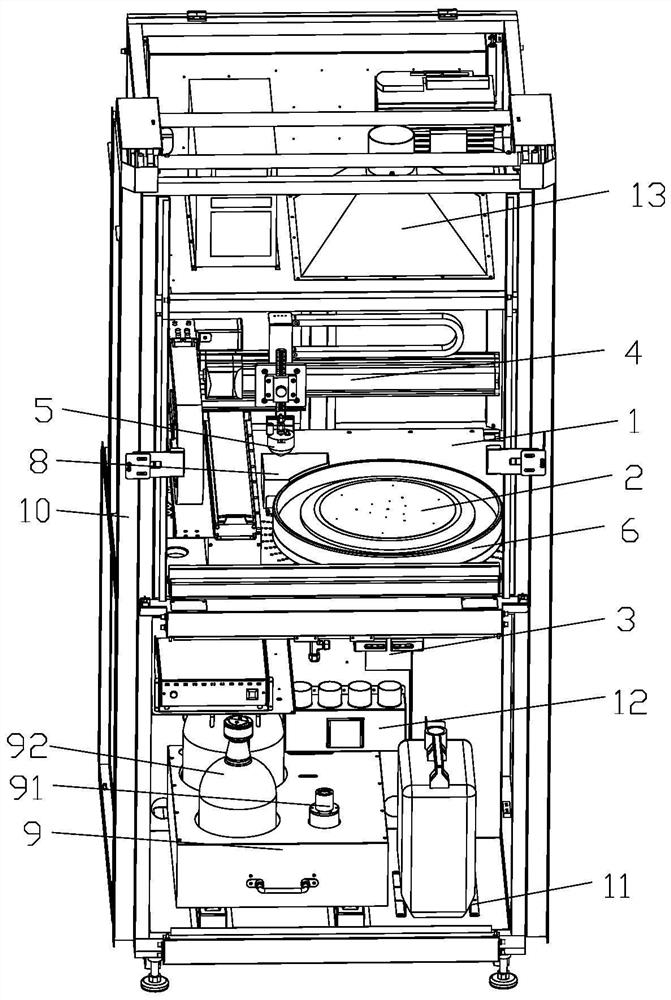

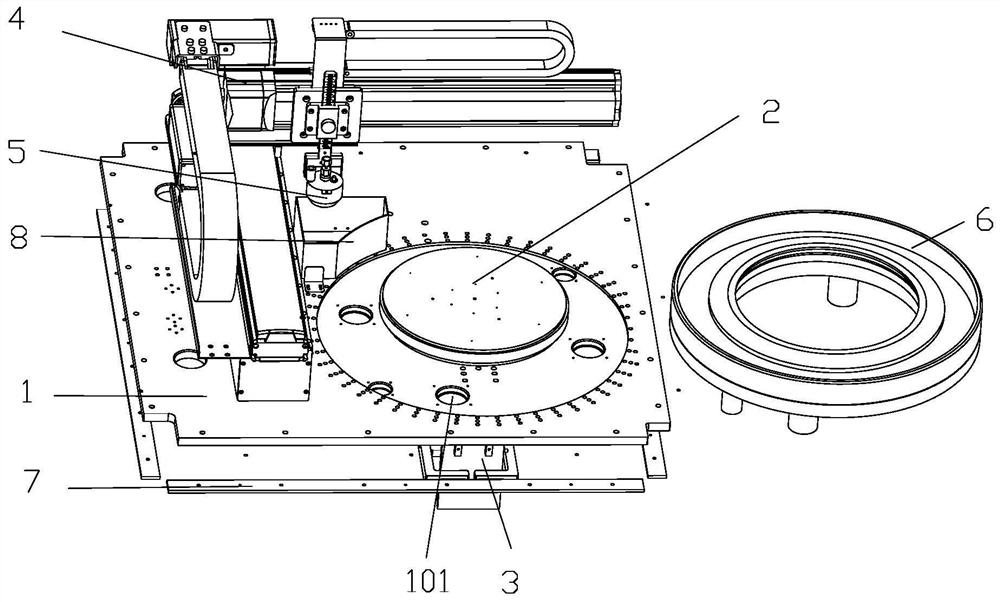

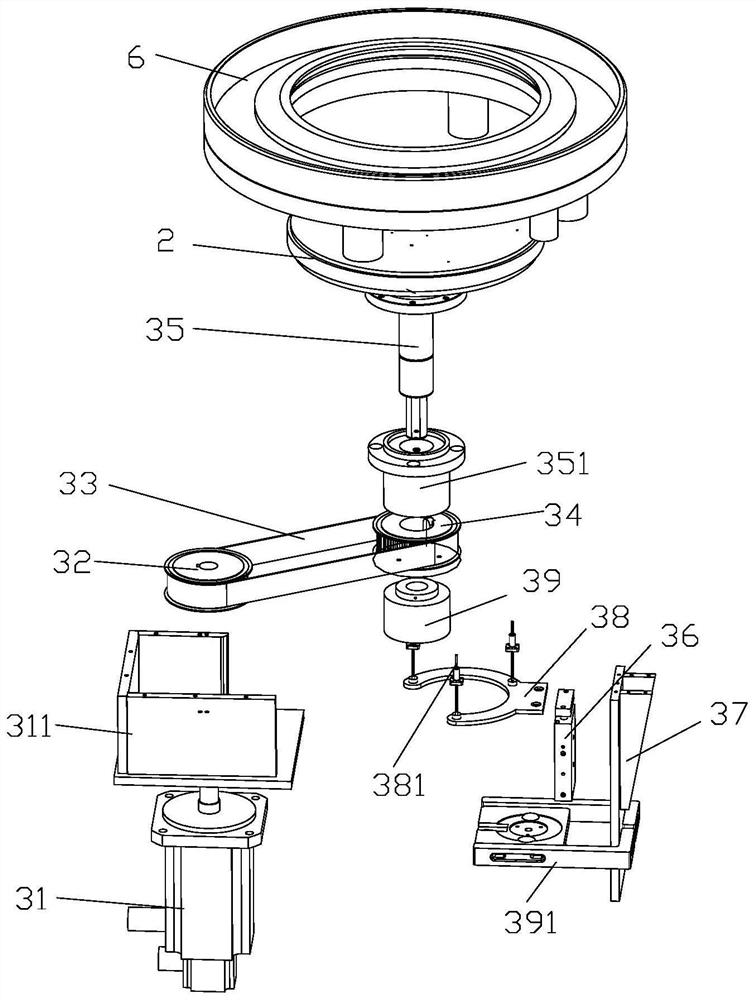

[0025] Such as figure 1 and figure 2 As shown, a fully automatic semiconductor wafer glue spraying equipment includes a frame 10, a glue spraying platform 1, a rotating disk 2, a rotary lifting drive device 3, a horizontal and vertical moving device 4, a nozzle 5 and a splash guard 6. The frame 10 is divided into upper, middle and lower layers, and the frame 10 is provided with an air suction port on the upper layer of the frame 10, and a suction cover 13 is provided on the air suction port. The suction hood 13 is arranged in a funnel shape. It can effectively absorb wind and prevent harmful substances from causing harm to the body. The upper layer of the rack 10 is also provided with an industrial computer and a driver. The glue spraying platform 1 is set on the middle layer of the frame 10, the rotating di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com