Method for mounting force-bearing conversion layer of large-area roof truss

An installation method and transfer layer technology, applied in truss-type structures, girders, trusses, etc., can solve the problems of slow construction progress, difficult to guarantee the quality of high-altitude operations, and high construction costs, and achieve the effect of meeting installation needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

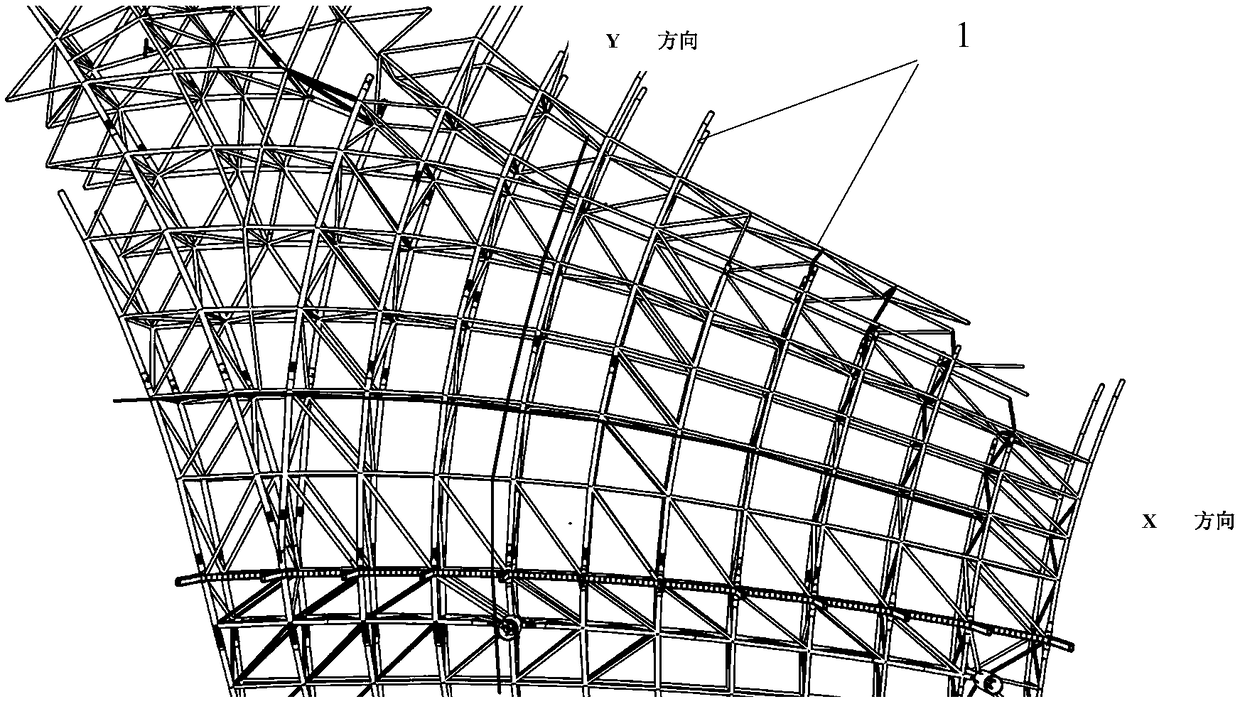

[0069] Such as image 3 As shown, the large-space roof frame mostly adopts steel truss structure, and most of them are hyperbolic shapes. Truss 1 mostly adopts the second force bar of the truss as a unit, and its force characteristics do not allow the suspenders of the later suspended ceiling to be directly connected to the middle of the two force bars of the truss. At the same time, the trend of the roof truss will not remain horizontal and vertical on the XY plane, and the elevation will not be uniform in the direction of the Z axis.

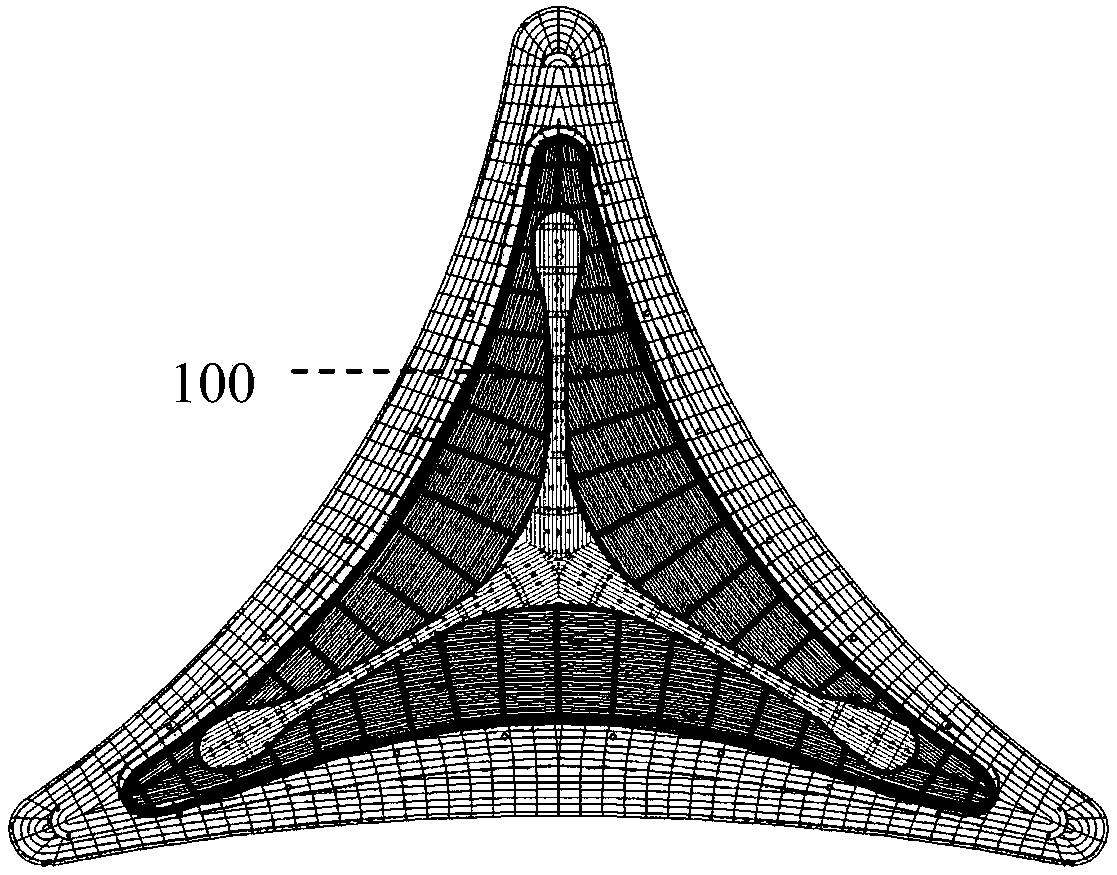

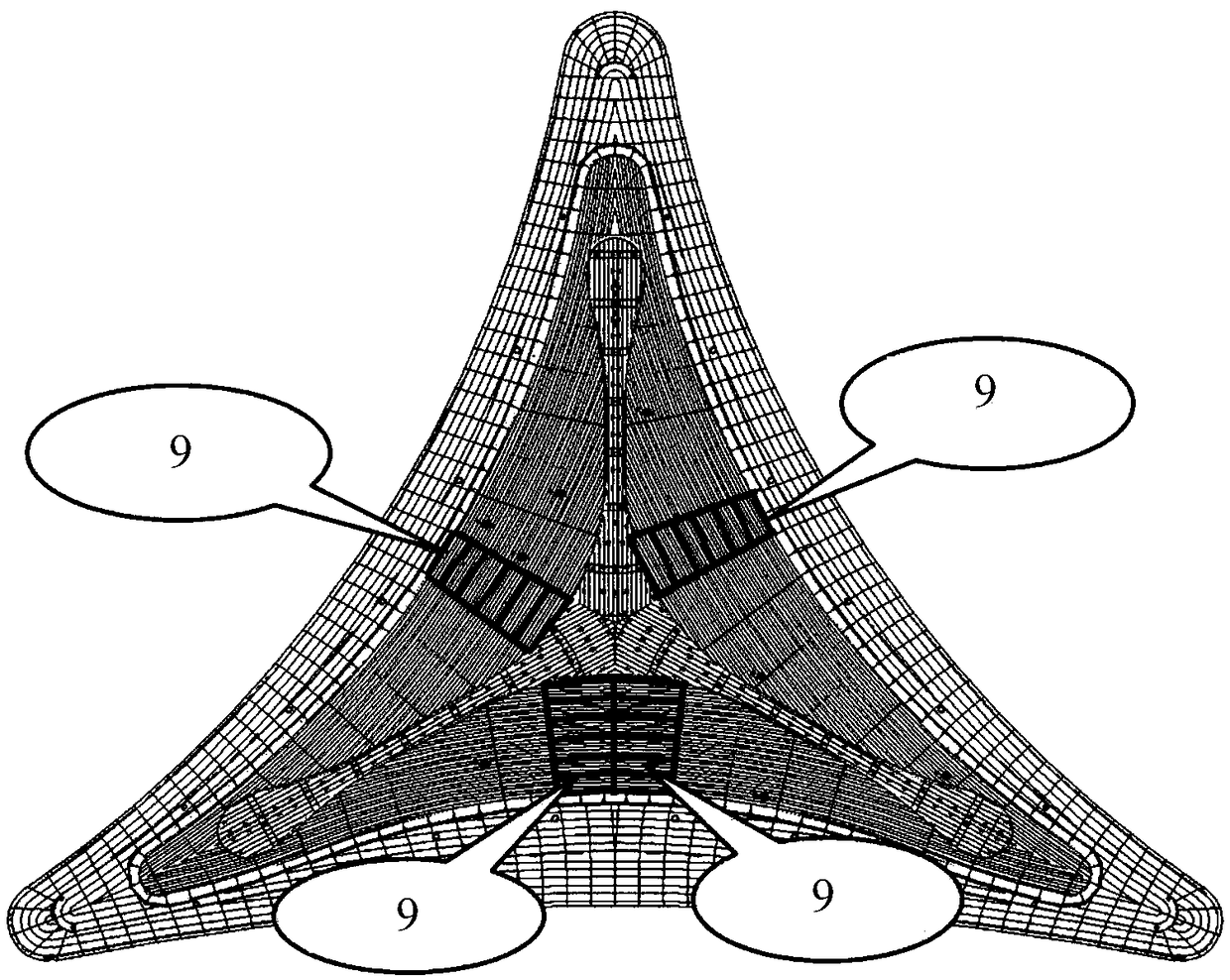

[0070] Such as Figure 1-35 As shown, the present invention provides a roof suspension system. The installation method of the large-area roof truss stress conversion layer includes a roof truss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com