A hollow interlayer fabric with profiling function

A technology of outer layer fabric and inner layer fabric, applied in the direction of fabric, woven fabric, multi-strand fabric, etc., can solve the problems of poor height consistency, high fiber volume content, etc., achieve structural strength improvement, good uniformity, and improve positioning accuracy and the effect of the scan range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

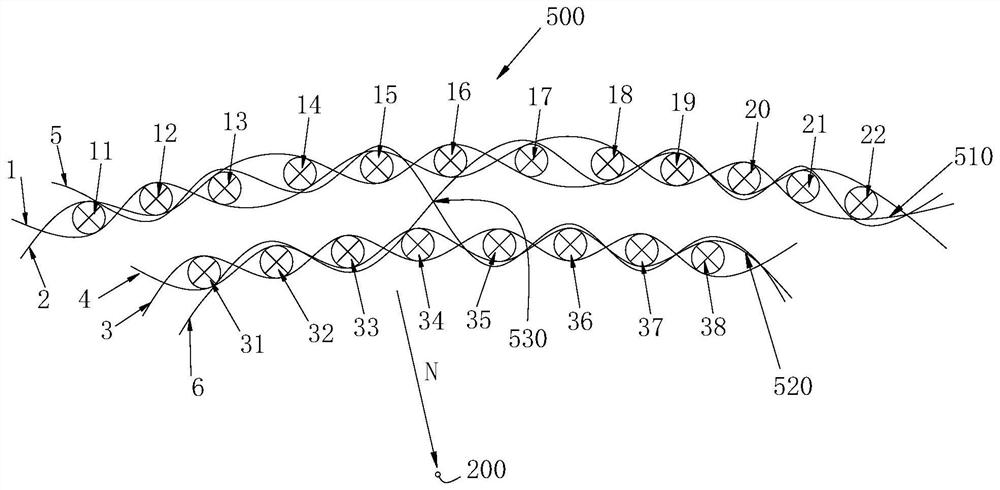

[0026] The present invention will be further described below in conjunction with accompanying drawing.

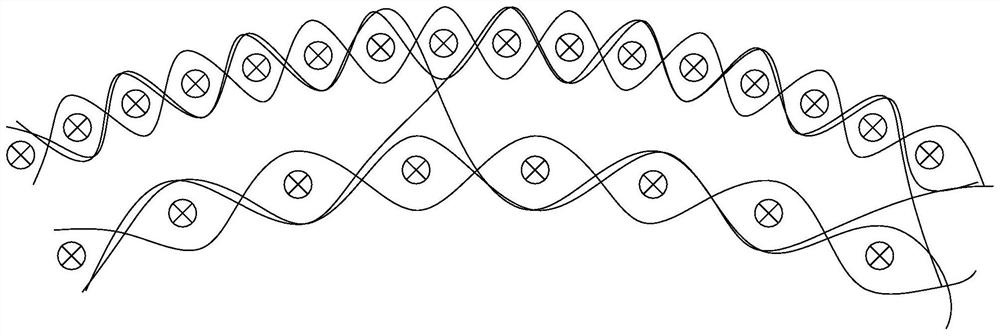

[0027] see figure 2 , a hollow interlayer fabric 500 with profiling function, having an axis 200, in figure 2 , the axis 200 is perpendicular to the paper, and for clarity, the axis is represented by a small circle. In this application, the direction toward the axis is referred to as the inner side. figure 2 In , the arrow N points to the inner side, and the direction opposite to the inner side is called the outer side, then the outer fabric of the hollow interlayer fabric is called the outer fabric, and the inner fabric is called the inner fabric.

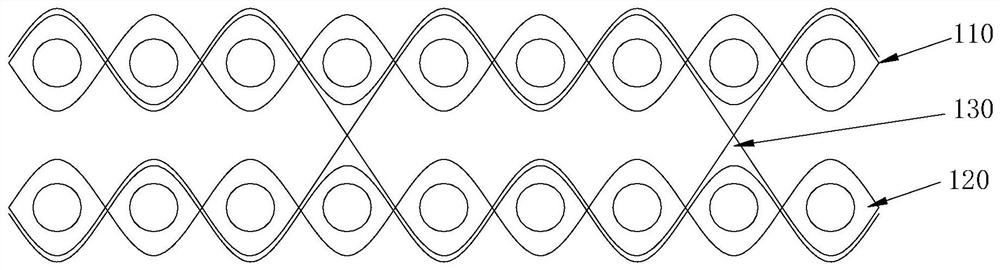

[0028] Relative to the axis 200, the hollow interlayer fabric 500 has a single curvature; the hollow interlayer fabric 500 has an outer fabric 510 and an inner fabric 520, and the inner fabric 520 and the outer fabric 510 have an asymmetric structure. The outer layer fabric 510 is formed by interweaving outer layer warp ya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com