A locking lock with a built-in motor

A locking structure and motor assembly technology, applied in the field of keys, can solve problems such as limited anti-theft performance, weak anti-theft performance, and hidden dangers, and achieve the effect of increasing anti-theft performance, improving the anti-theft level, and overall appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

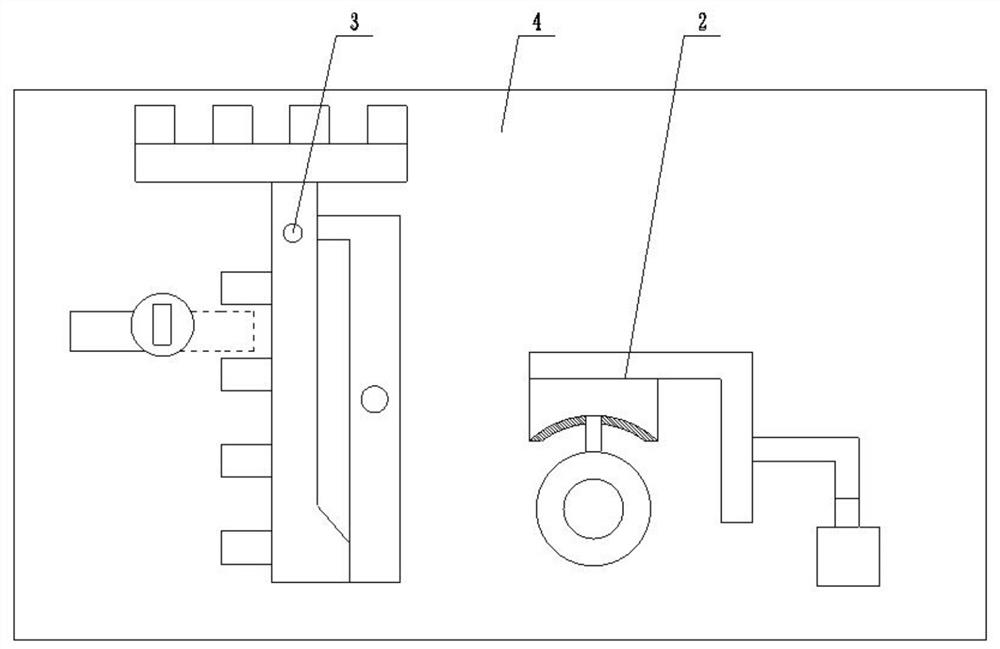

[0026] Such as Figure 1 to Figure 7 As shown, a locking lock with a built-in motor of the present invention includes a key 1, a motor assembly 2, a locking structure 3 and a lock body 4, the motor assembly 2 and the locking structure 3 are all arranged in the lock body 4, and the motor assembly 2 is used to lock or release the handle, the locking structure 3 can only be opened by the matching key 1; and the locking structure 3 can prevent the lock body 4 from being opened by turning the inner handle;

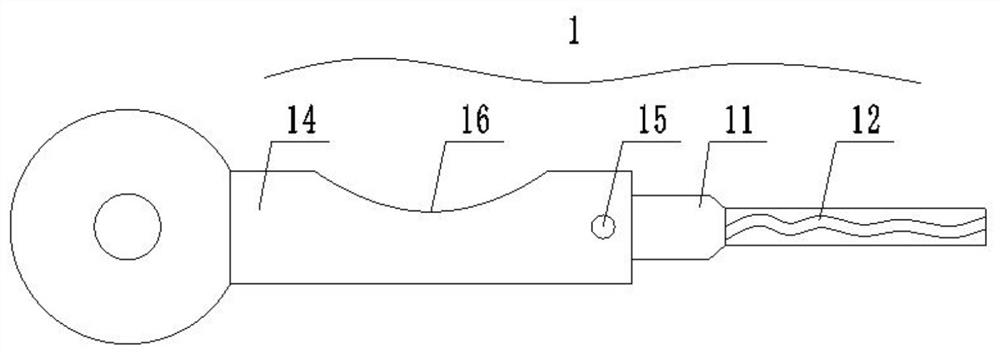

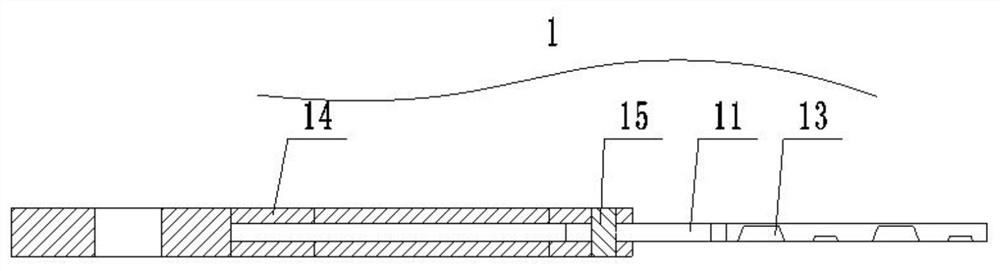

[0027] The structure of the key 1 includes a key body 11, the front and back of the key body 11 are provided with a first key slot 12, and both sides of the key body 11 are also provided with a second key slot 13;

[0028] The structure of the motor assembly 2 includes a lock handle linkage 22, the upper end of the lock handle linkage 22 is provided with a self-locking rod 23, and a self-locking block 24 is arranged above the self-locking rod 23, and the self-locking block 24 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com