Sewing machine for automatically adjusting line taking for thickness of sewing material and line taking adjusting method thereof

A technology of automatic adjustment and sewing material thickness, applied in sewing machine components, sewing machine control devices, sewing equipment, etc., can solve the problem that the thread take-up mechanism cannot adapt to the thickness of the fabric, and achieve the effect of good sewing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

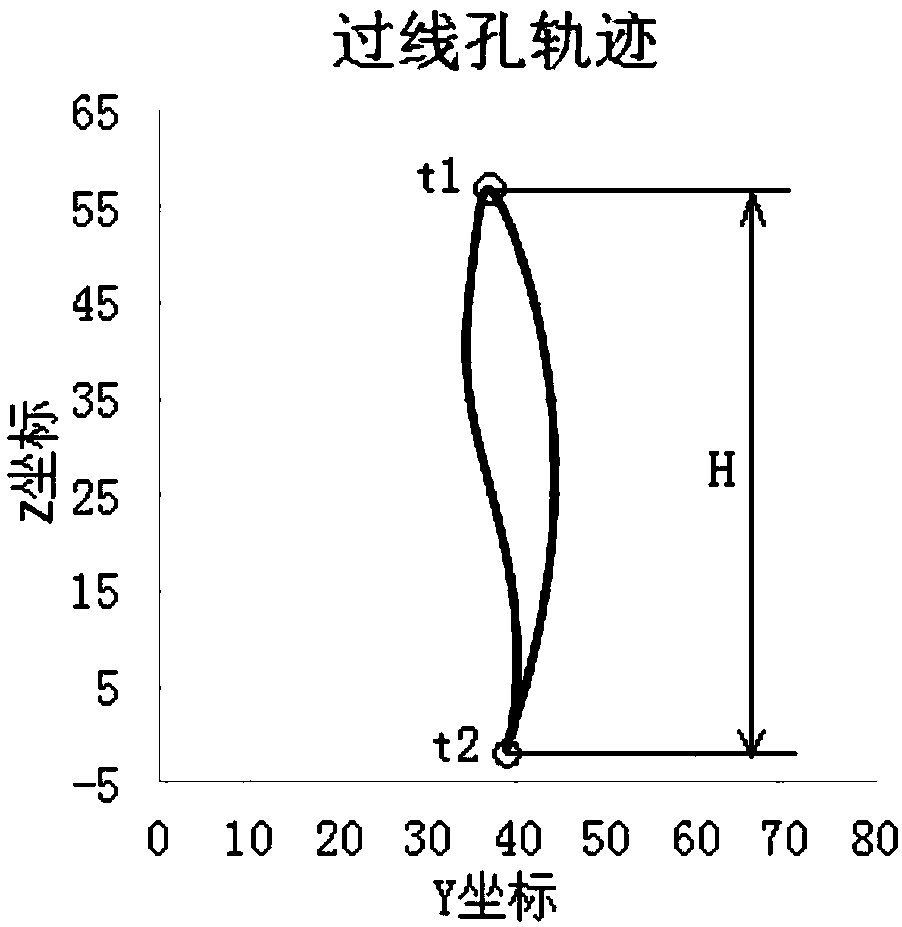

[0086] The thread take-up mechanism of this embodiment is identical in structure with embodiment one, and the difference is: see Figure 14 As shown, the fixed position of the above-mentioned driving member 2. In this embodiment, by adjusting the fixed position of the driving member 2, the above-mentioned connecting rod assembly can form three states, the first state (see Figure 15 shown) and the second state (see Figure 16 shown) symmetrically located in the third state (see Figure 17 shown) on both sides, and the third state is in a straight line state (see Figure 17 As shown), the first state and the second state respectively make the thread passing hole 51 of the thread take-up lever 5 be at the highest point, and the third state makes the thread passing hole 51 of the thread taking lever 5 be at the lowest point. In this embodiment, the timing of the thread take-up can be changed when the stroke of the thread-passing hole of the thread take-up lever 5 remains uncha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com