Tightening device for longitudinal travelling gear of flame cutter

A flame cutting machine and travel gear technology, applied in the direction of gas flame welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as jamming, poor running stability of the frame, and affecting cutting accuracy, and achieve stable longitudinal positioning accuracy, The effect of ensuring cutting accuracy and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

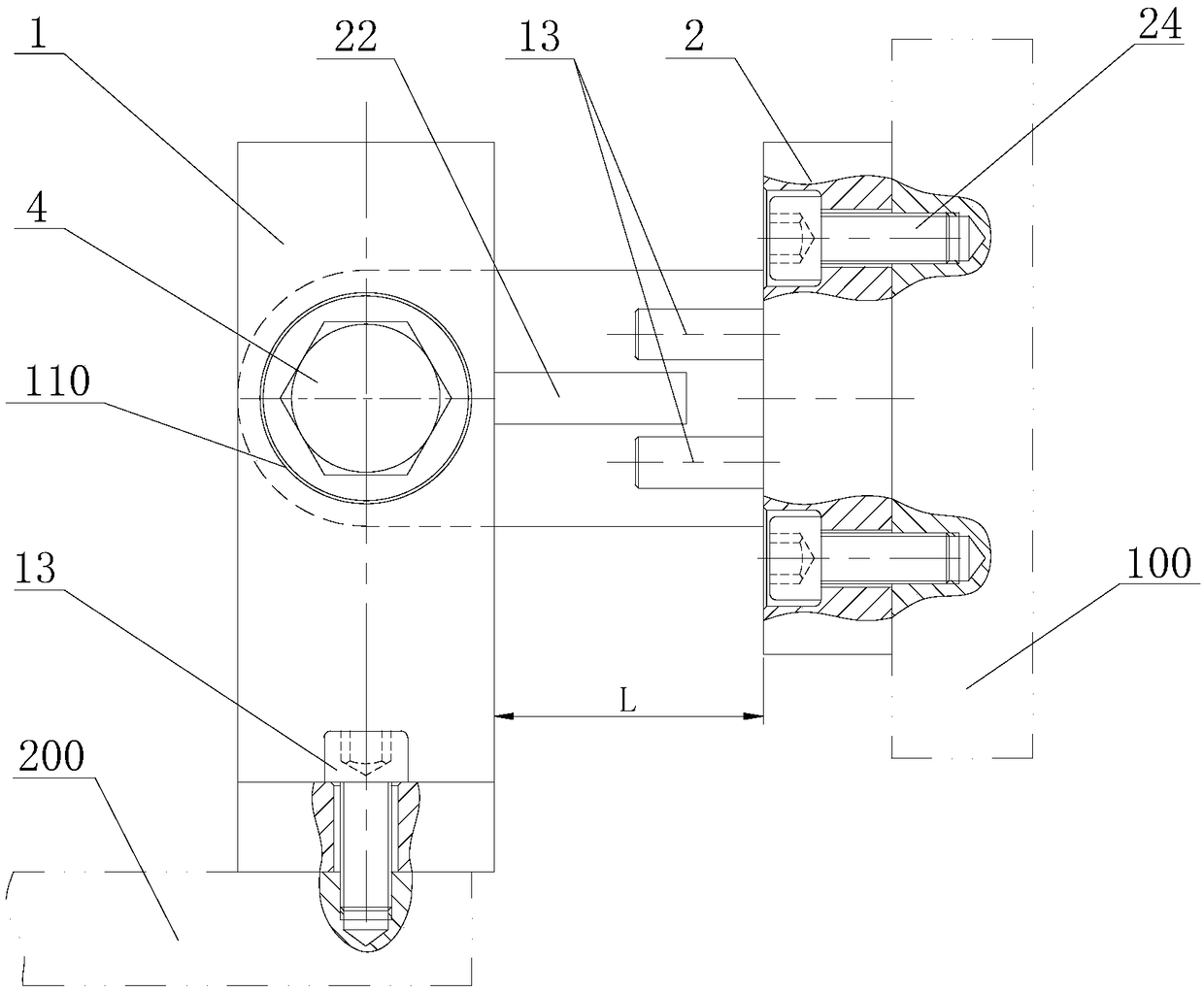

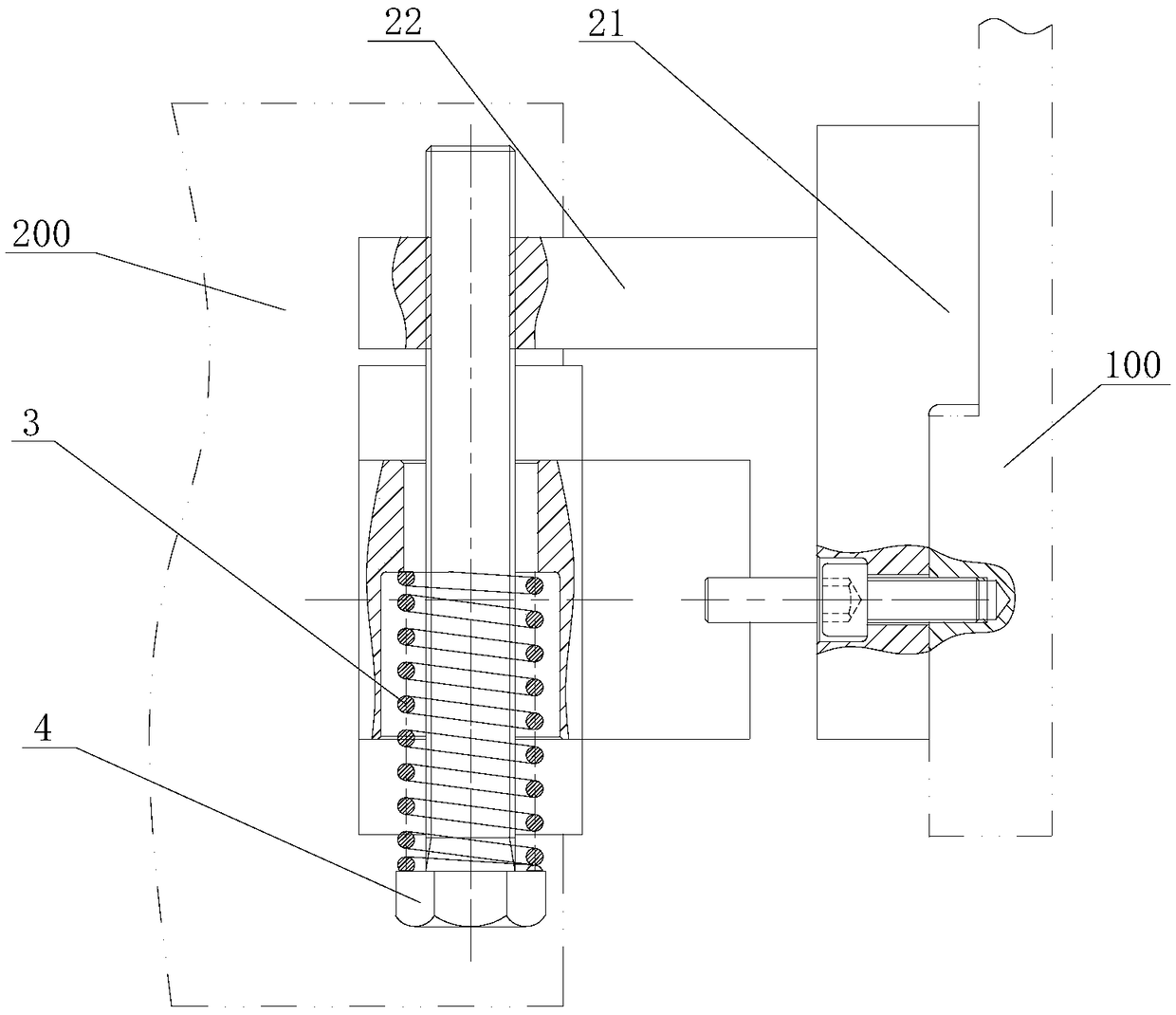

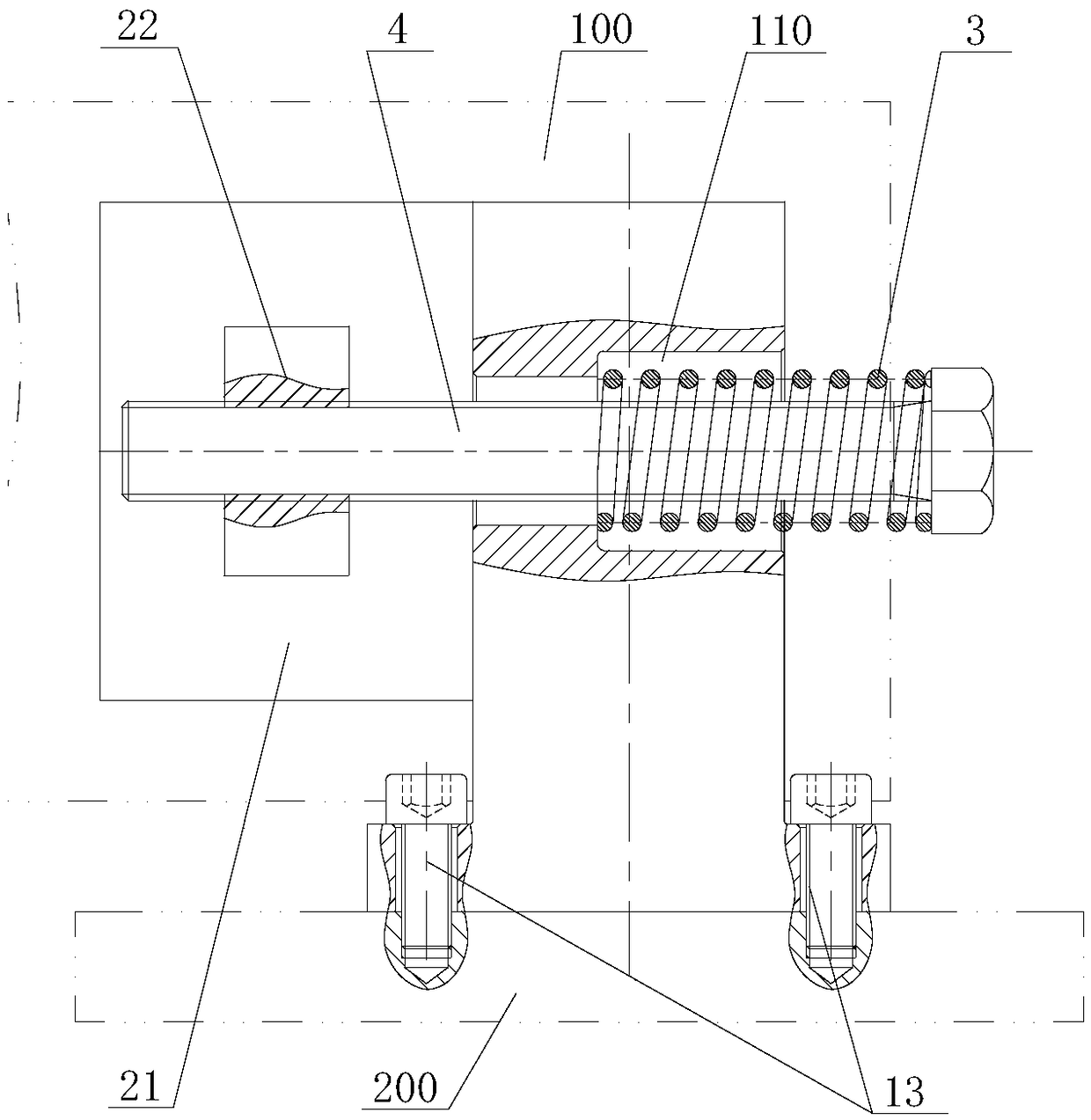

[0023] The frame of the flame cutting machine includes end beams on both sides and a beam connected to the end beams on both sides; the longitudinal traveling mechanism includes a longitudinal guide rail with an I-shaped cross section, and longitudinal teeth installed A motor frame 200 is respectively arranged at the afterbody of the end beams 100 on both sides, and a geared motor is installed on each motor frame 200, and a gear meshing with the longitudinal rack is installed on the rotating shaft of each geared motor.

[0024] see Figure 1 to Figure 5c , the abutting device of the longitudinal traveling gear of the flame cutting machine of the present invention comprises a first bracket 1, a second bracket 2, a spring 3 and a connecting bolt 4; wherein,

[0025] The first bracket 1 comprises a bracket body 11 that is a quadrangular prism and a limiting plate 12 that is h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com