An all-round contact socket

A contact-type, all-round technology, which is applied in the direction of connecting and connecting parts of the device, and the device of joining/disconnecting the connecting parts, etc., can solve the problems of easy heat generation, disappearance, shrapnel wear, etc., so as to increase the contact area and make it difficult to contact Bad, the effect of reducing the difficulty of plugging and unplugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

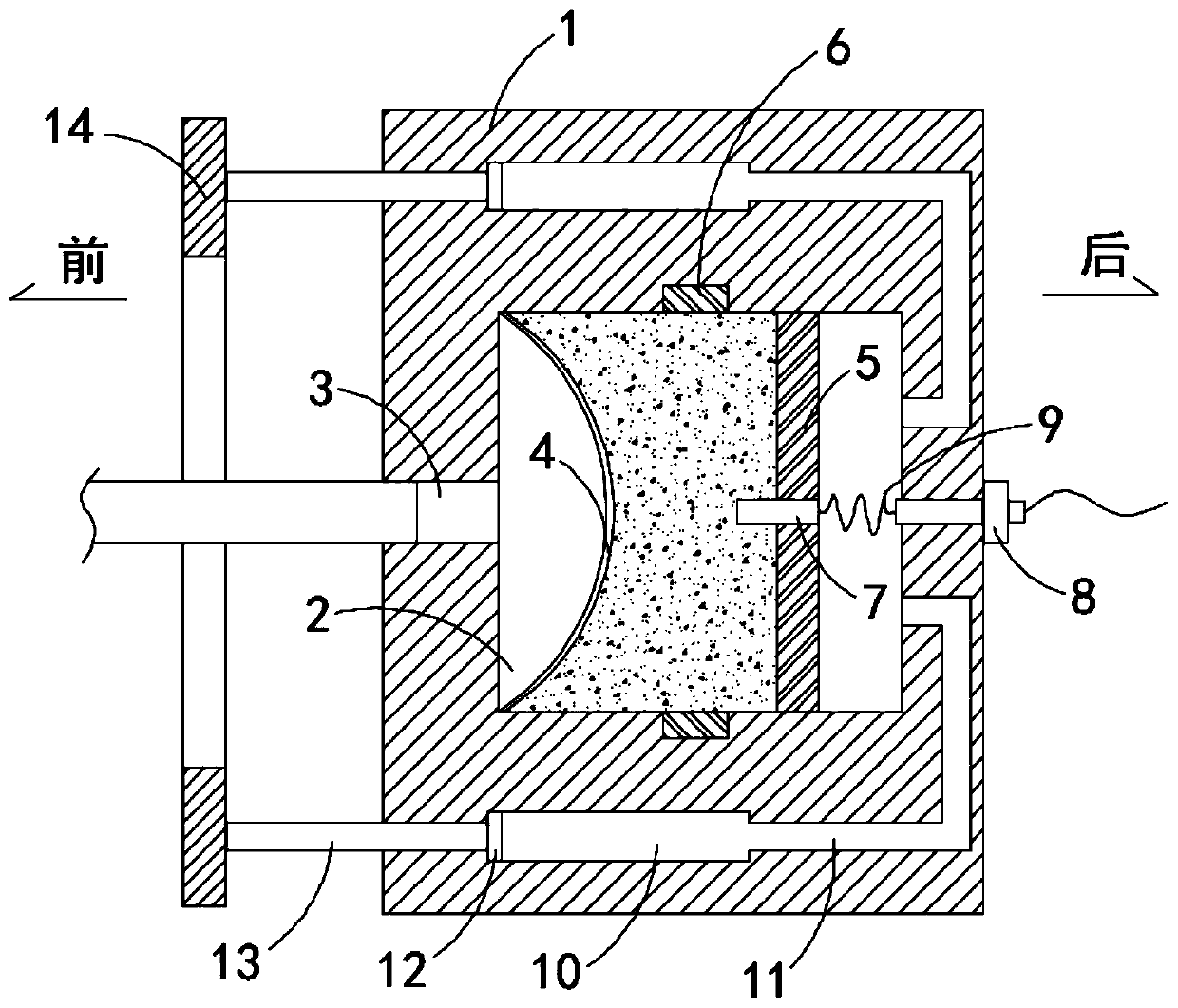

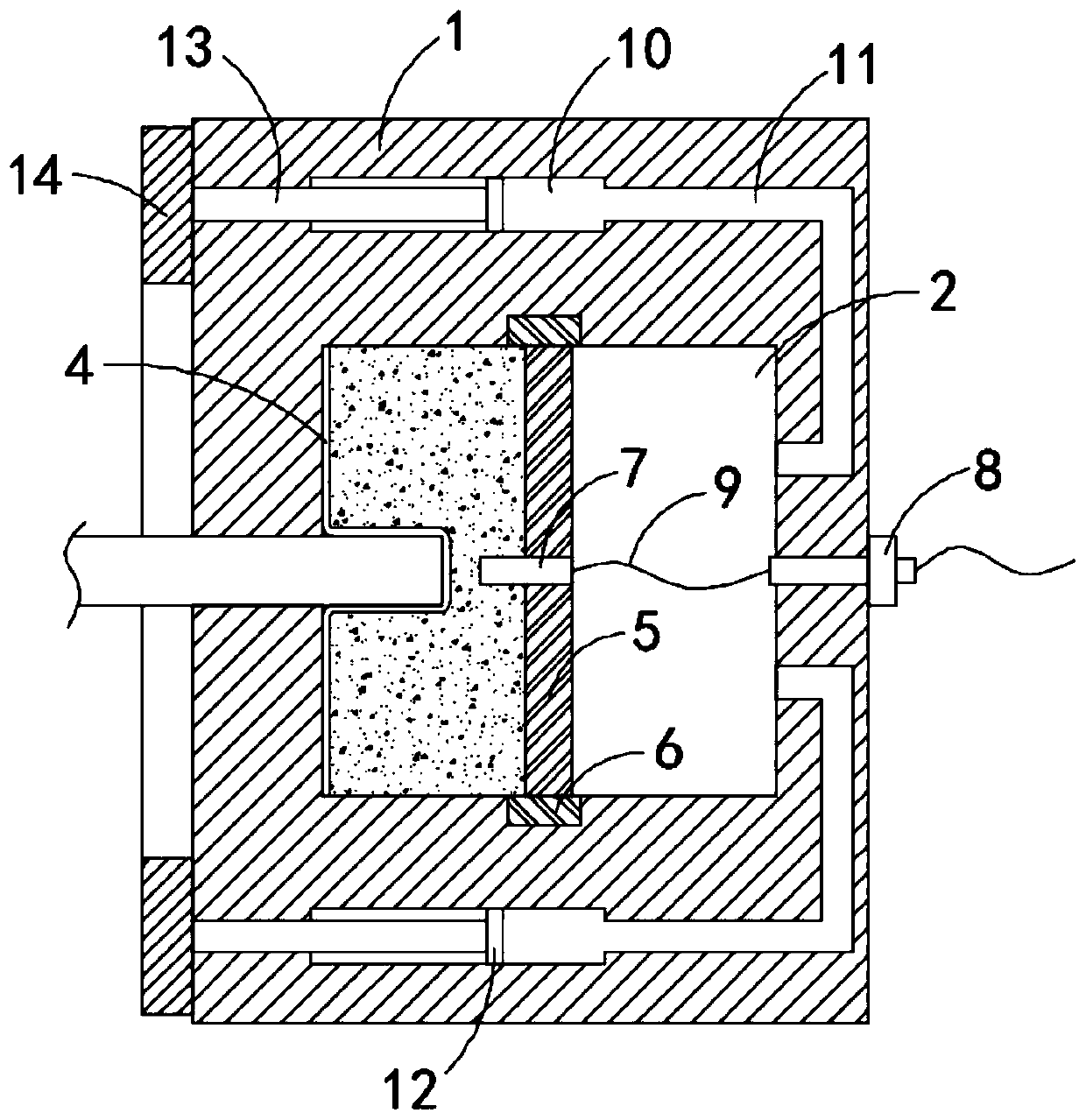

[0018] Such as Figure 1-2 As shown, an all-round contact socket includes a mounting block 1. Two conductive cavities 2 are arranged in the mounting block 1. Jacks 3 are arranged on the front side wall of the conductive cavity 2. The two jacks 3 are connected to the plug respectively. Corresponding to the two conductive insert rods, the outer cover of the jack 3 is provided with an elastic conductive film 4, the edge of the elastic conductive film 4 is fixedly connected with the side wall of the conductive cavity 2, and the rear side of the elastic conductive film 4 is provided. The airtight space surrounded by the sealed magnetic sealing plate 5, the elastic conductive film 4, the magnetic sealing plate 5 and the conductive chamber 2 is filled with mercury, and a permanent magnet ring 6 for positioning the magnetic sealing plate 5 is fixedly connected in the airtight space. The magnetic sealing plate 5 and the permanent magnet ring 6 attract each other.

[0019] In this embo...

Embodiment 2

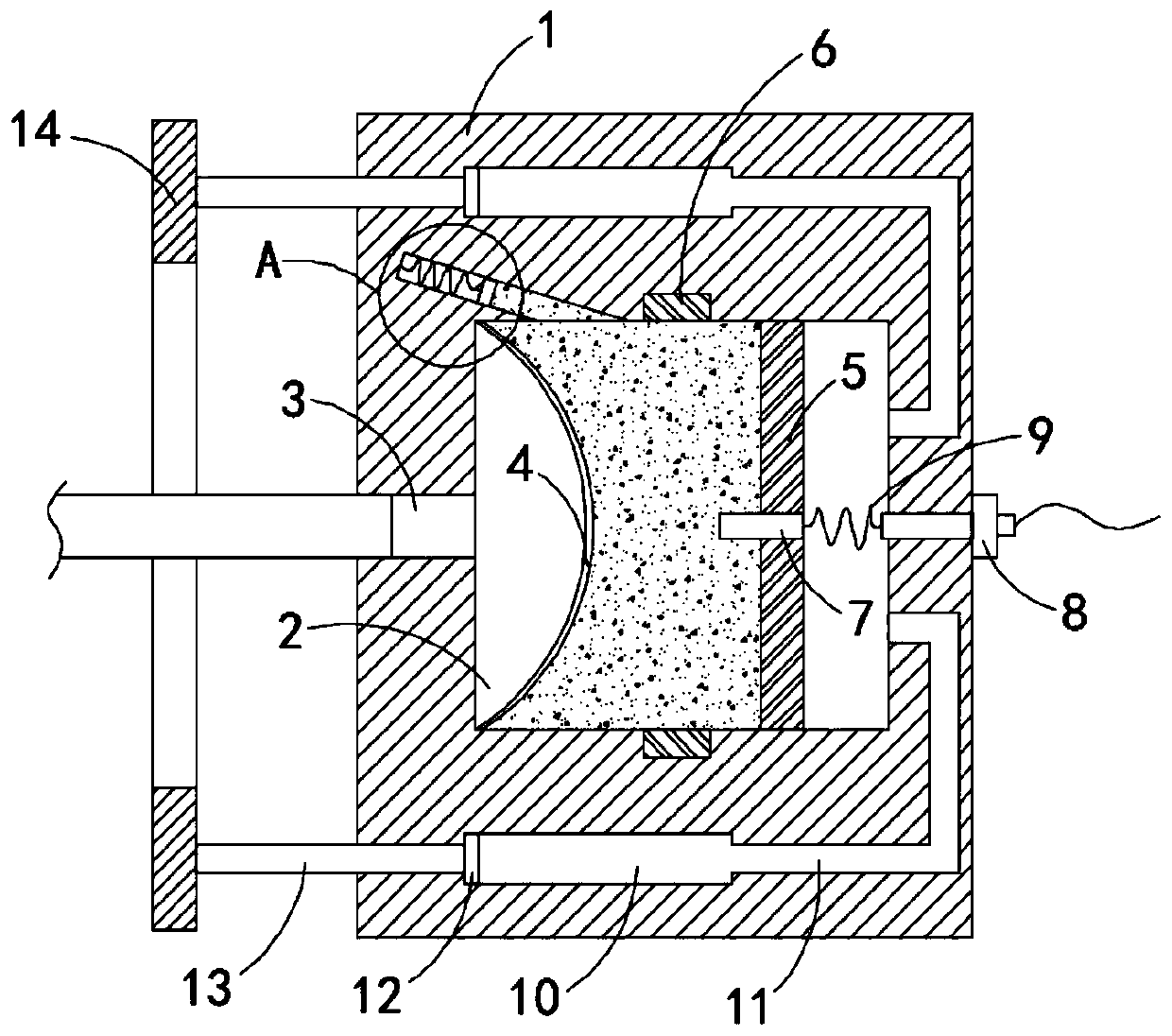

[0023] Such as Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 is that: the side wall of the closed space surrounded by the elastic conductive film 4, the magnetic sealing plate 5 and the conductive cavity 2 is provided with an adjustment groove 15, and the adjustment groove 15 is in the form of Slanted setting, the sliding seal in the adjustment groove 15 is connected with a sealing block 16, and a return spring 17 is fixedly connected between the sealing block 16 and the groove bottom of the adjustment groove 15, and the elastic force of the return spring 17 is greater than that of the elastic conductive film 4.

[0024] In this embodiment, when the mercury expands due to the influence of the ambient temperature or the heat generated by the socket for a long time, it will push the sealing block 16 to move, so that part of the mercury enters the adjustment groove 15 to play a buffering role. Under the action of the spring 17, the sealing block 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com