Electromagnetic clutch coil automatic assembly system for compressor

An electromagnetic clutch and assembly system technology, which is applied in coil manufacturing and other directions, can solve the problems of accurately positioning the thread end under the crimping machine and uneven wire twisting and pinching, and achieve the effects of increasing production efficiency, improving product quality, and high linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

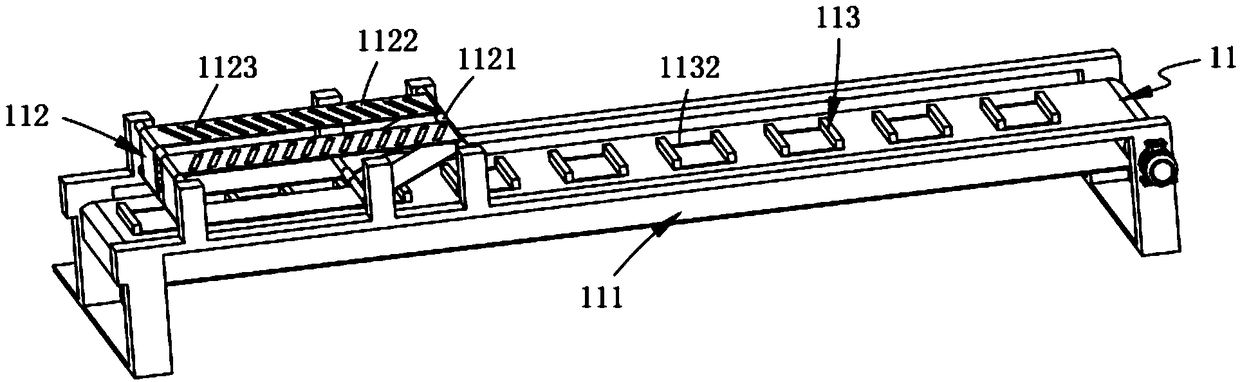

[0078] like figure 1 As shown, the fully automatic assembly system for electromagnetic clutch coils for compressors includes:

[0079] A first-level flattening mechanism 1, the first-level flattening mechanism 1 includes a straightening assembly 11 and an outlet assembly 12 located at the output end of the straightening assembly 11 and perpendicular to the transmission direction of the straightening assembly 11;

[0080] The epicyclic mechanism 2, the epicyclic mechanism 2 includes a frame 21 for installing the straightening assembly 11, a switching assembly 22 arranged on the frame 21 and located below the straightening assembly 11 and installed on the The drive mechanism 23 on the frame 21;

[0081] The two-level flattening mechanism 3, the two-level flattening mechanism 3 is arranged in several groups on the switching assembly 22, which includes a receiving assembly 31 installed on the switching assembly 22, a sliding set under the receiving assembly 31 The first tighteni...

Embodiment 2

[0131] like Figure 11 , Figure 12 and Figure 13 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0132] further, such as Figure 11 and Figure 12 As shown, the coil upper assembly 42 includes:

[0133] The supporting member 421, the supporting member 421 includes a frame platform 4211 arranged on one side of the crimping machine 41 and set on the same level as the workbench of the crimping machine 41, set on the frame platform 4211 and Two sets of slide rails 4212 and a feeding bucket 4213 fixedly arranged on the vehicle frame platform 4211 and provided with a gap between the upper surface of the vehicle frame platform 4211 are arranged along the width direction of the vehicle fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com