Automatic film tearing machine and film tearing process thereof

A film machine and automatic technology, applied in the direction of layered products, lamination auxiliary operation, lamination, etc., can solve the problems of difficult film tearing, low film tearing efficiency, and affecting product quality, so as to reduce the damage of the substrate, Improve the efficiency of tearing film and increase the effect of tearing film production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing:

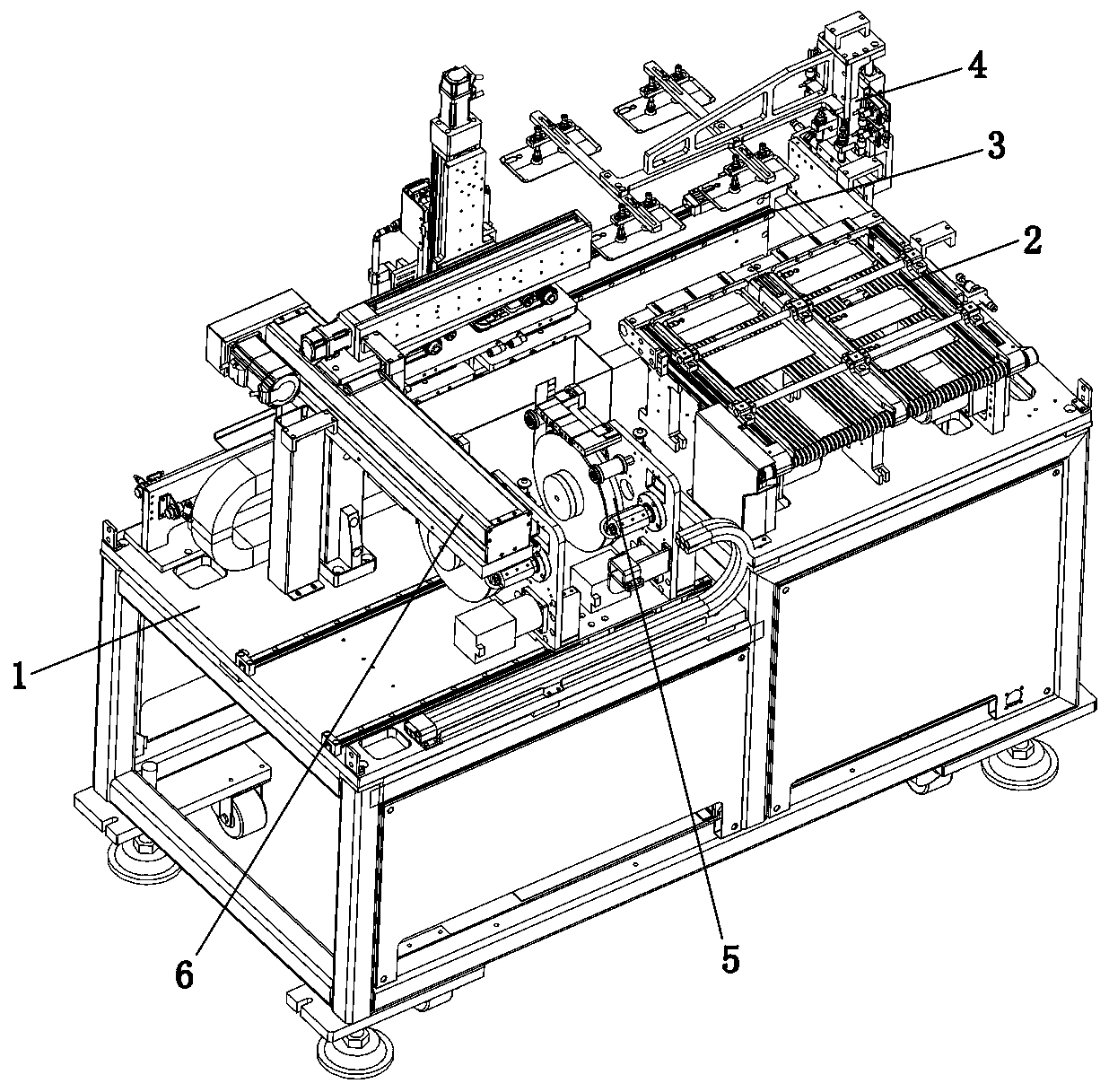

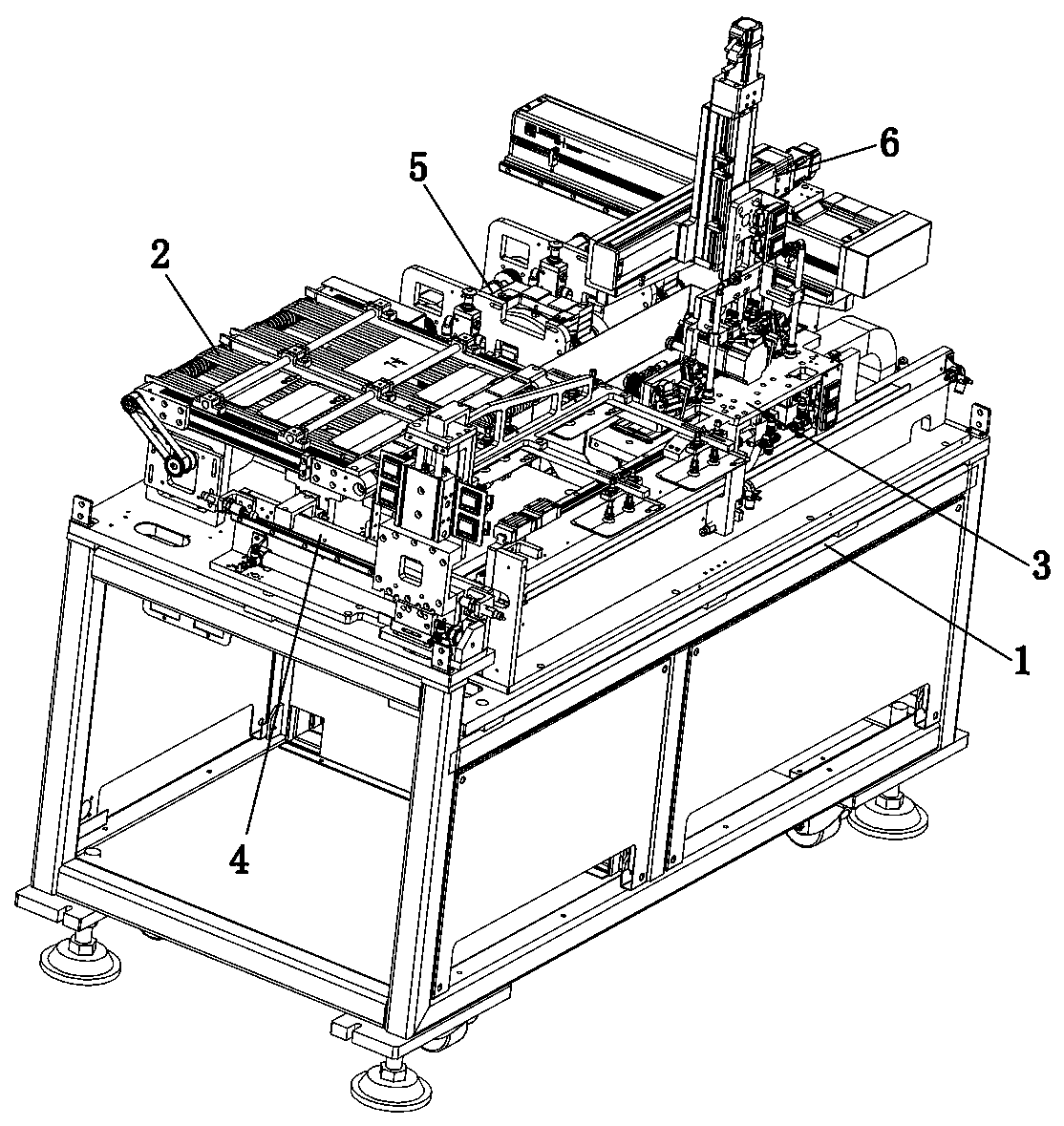

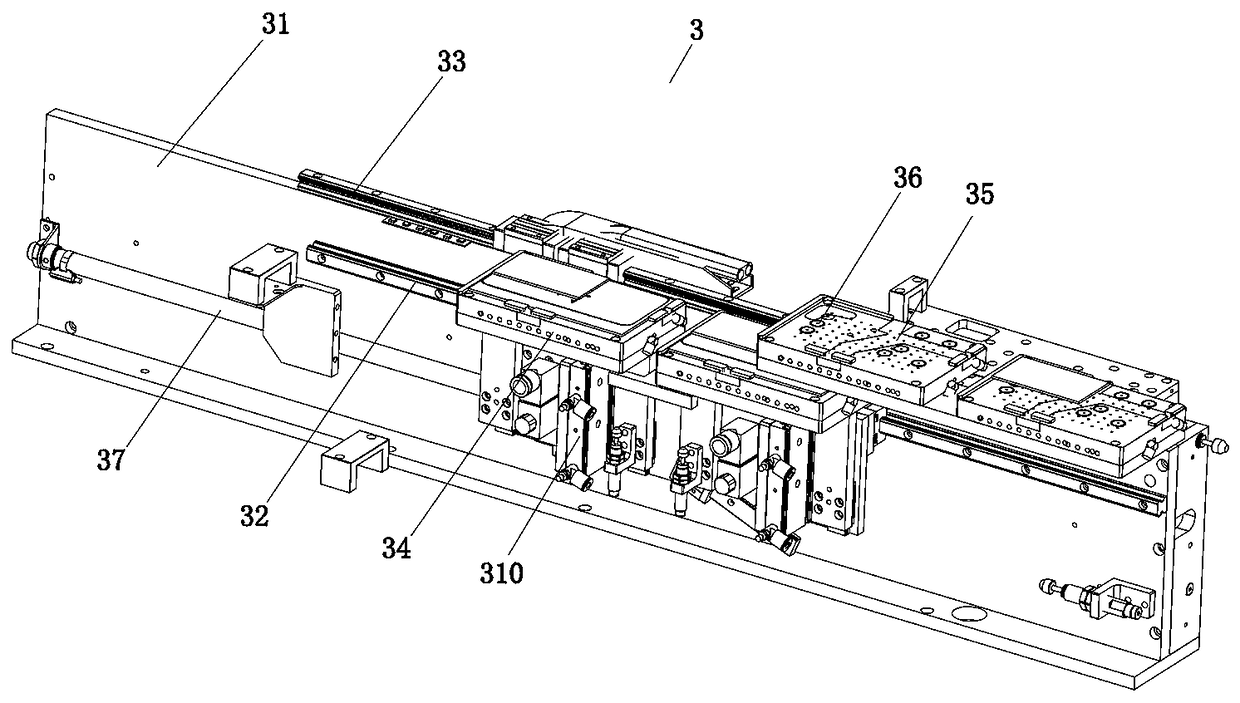

[0039] Such as Figure 1 to Figure 11 As shown, the technical scheme adopted by the present invention is as follows: an automatic film tearing machine and its film tearing process, including a conveyor belt 2, a lifting and sliding platform 3, a retrieving manipulator 4, an easy-to-tear sticker export mechanism 5 and a film tearing mechanism 6. Among them, the above-mentioned conveyor belt 2 is horizontally arranged on the frame 1, and the substrate to be torn off is placed on the conveyor belt 2, and the substrate is transported forward in a straight line; the above-mentioned lifting and sliding platform 3 is arranged on the conveyor belt 2, and extend horizontally to one side of the conveyor belt 2; The base material is taken out and placed on the lifting and sliding platform 3; the above-mentioned easy-to-tear sticker export mechanism 5 is set on one side of the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com